Special thermostat for online transformer oil detection chromatography columns

A technology for transformer oil and chromatographic column, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult heating temperature control, low safety factor, and difficulty in meeting product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

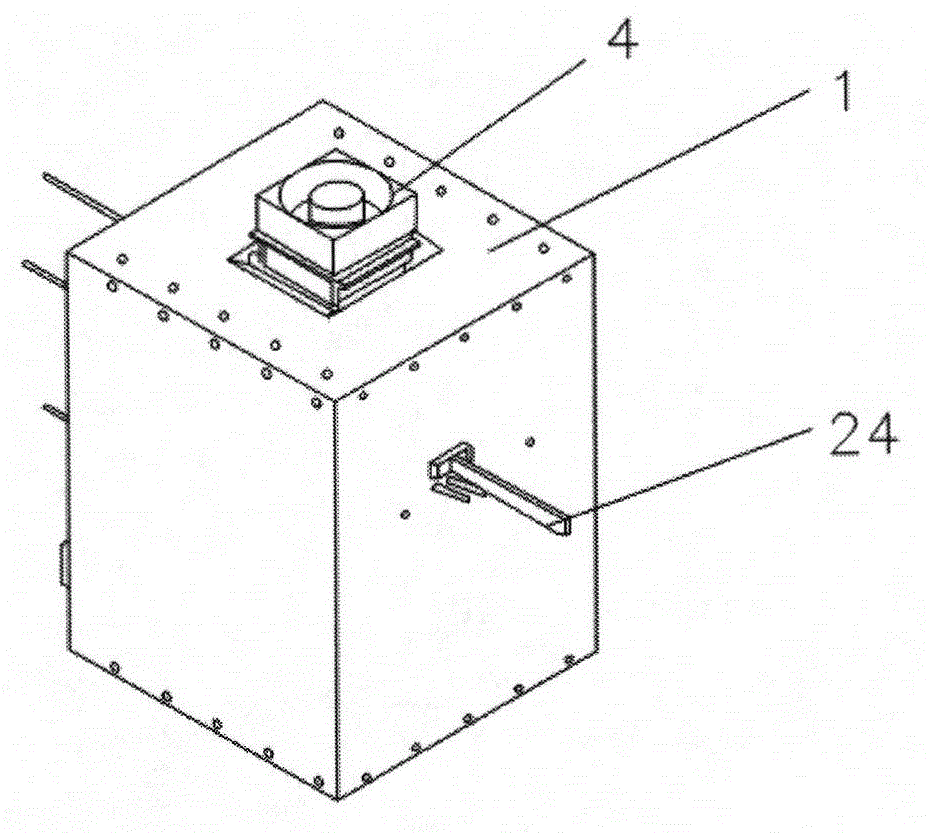

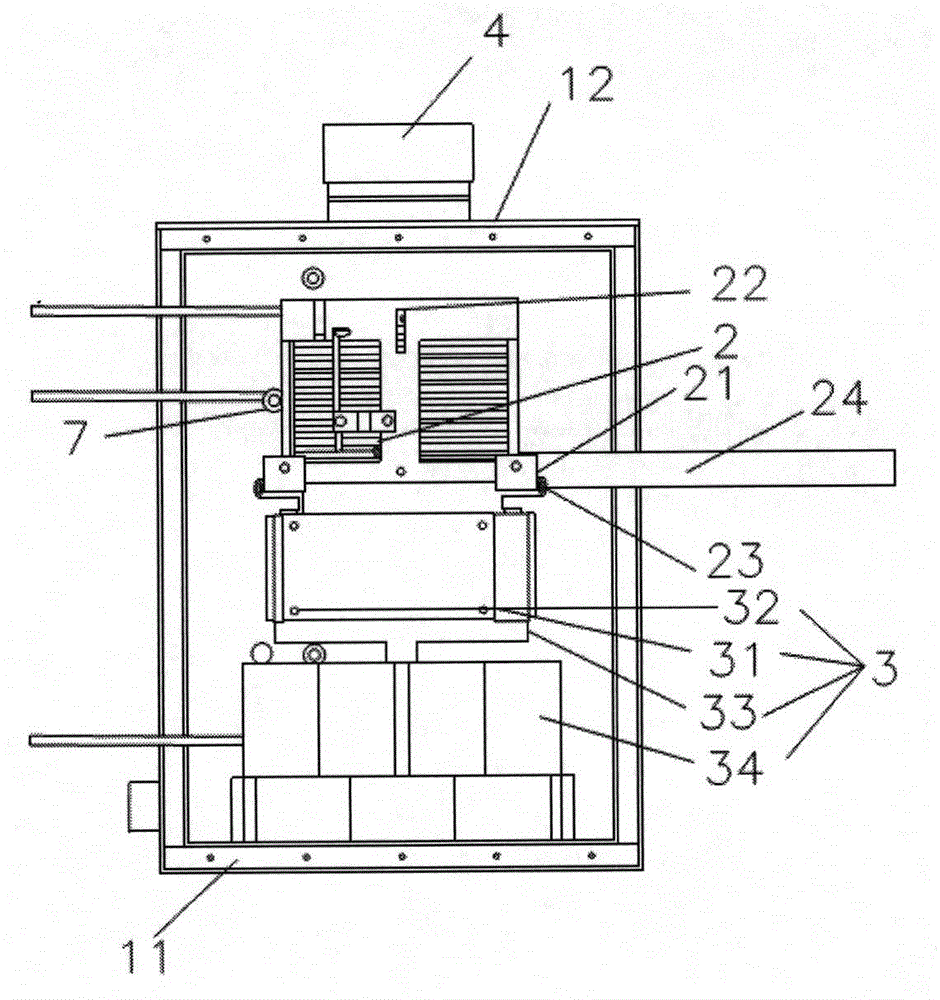

[0014] Such as figure 1 and figure 2 As shown, a special constant temperature box for on-line detection of transformer oil chromatographic column, including a box body 1, the box body 1 is divided into an inner box 11 and an outer box 12, and a central processing unit, an oil chromatographic column 2 and a heating device are installed in the inner box 11 3. The back of the outer box 12 is provided with binding posts, the top of the outer box 12 is provided with a cooler 4, the cooler 4 is connected to the inner box 11, the oil chromatography column 2 is set on the oil chromatography column base 21, and the oil chromatography column base 21 Connected with the support ring 22, the oil chromatographic column base 21 is provided with an oil chromatographic column support base 23, and the oil chromatographic column support base 23 is connected with the heating device 3, and the heating device 3 includes a finned radiator 31, a heating plate 32 , Heating device base 33 and high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com