Three-dimensional flow field test method based on single light-field camera

A technology of light field camera and three-dimensional flow field, which is applied in the direction of full-field flow measurement, fluid velocity measurement, and measurement devices, which can solve the problems of unsatisfactory calculation accuracy and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

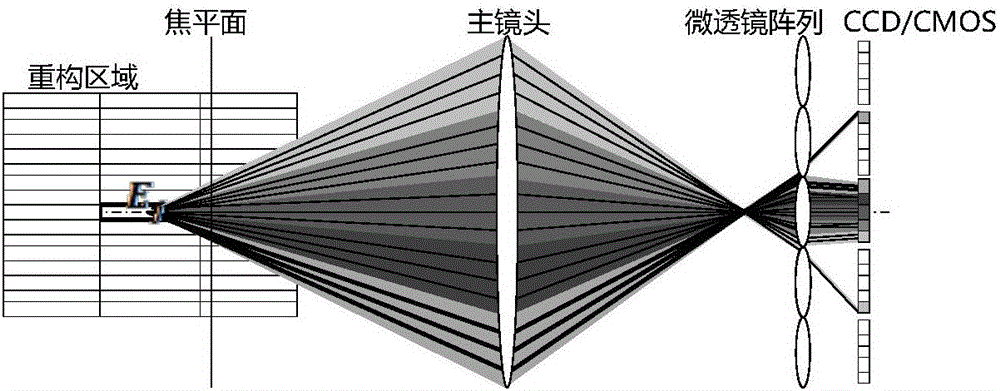

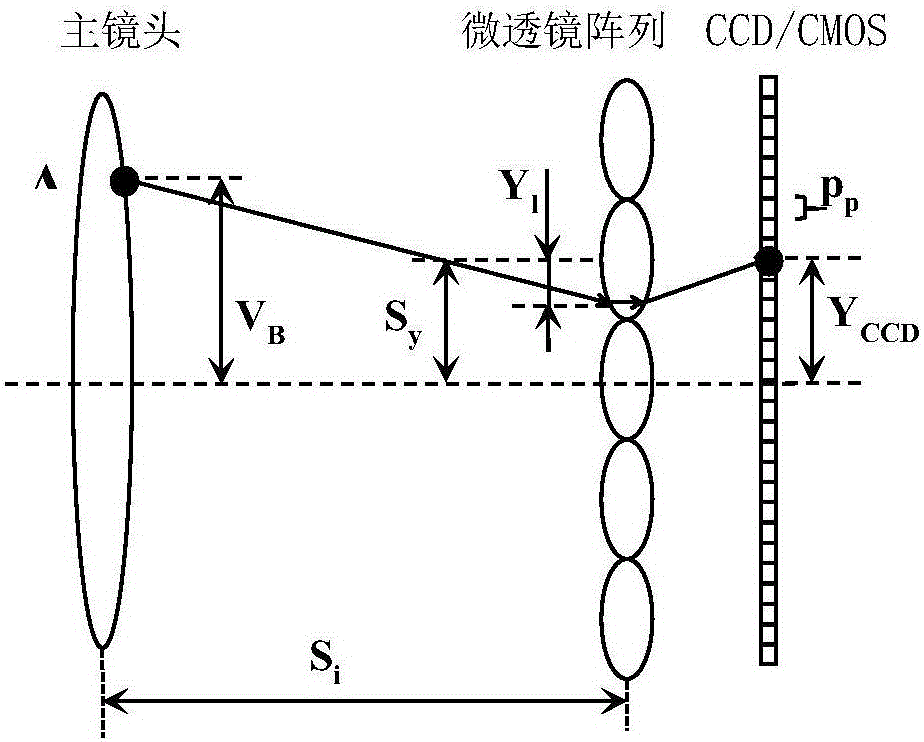

[0057] A method for testing a three-dimensional velocity field of a flow field based on a single light field camera of the present invention obtains the three-dimensional velocity field distribution of the flow field through a single viewing angle measurement. Contains the following steps:

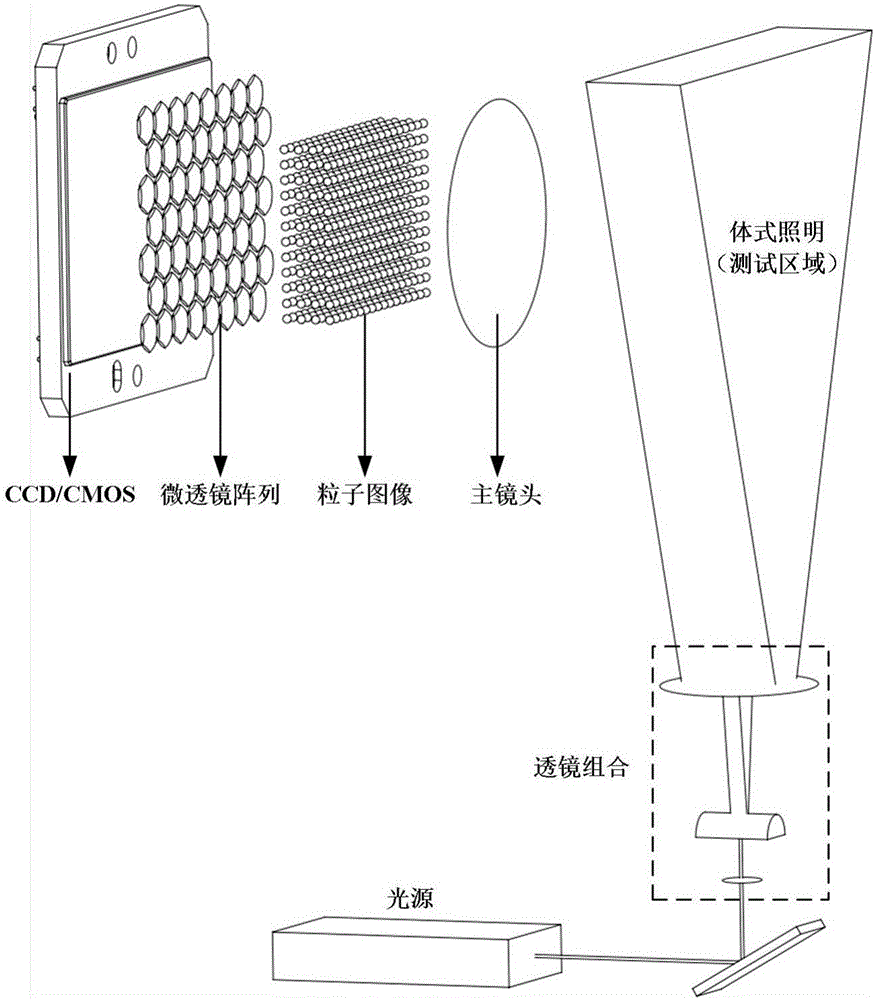

[0058] 1) Sprinkle tracer particles in the flow field to be measured (hollow glass beads of 20-30 microns are generally used in water; liquid droplets of about 1 micron or titanium dioxide particles of several hundred nanometers are generally used in air), according to figure 1 In the way of high-brightness light sources (laser, LED or high-brightness projectors) to provide body lighting; then use high-resolution or high-speed image sensors (CCD or CMOS) and micro-lens arrays (MLA) precision packages (ie light field cameras) , hereinafter referred to as a single light field camera) to capture time-series light field pictures of tracer particles.

[0059] 2) Perform preprocessing on the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com