Optical fiber connector assembly and its optical fiber plug and optical fiber receptacle

A technology of optical fiber connectors and plug pins, which is applied in the direction of optical components, instruments, optics, etc., can solve the problem of poor alignment of connector holes, poor alignment accuracy of connectors, and failure to meet the requirements of optical fiber contacts. Alignment requirements and other issues to achieve the effect of meeting the alignment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

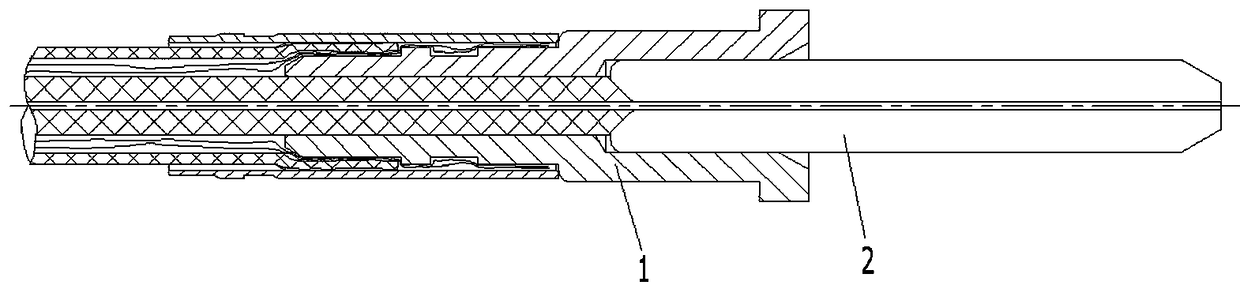

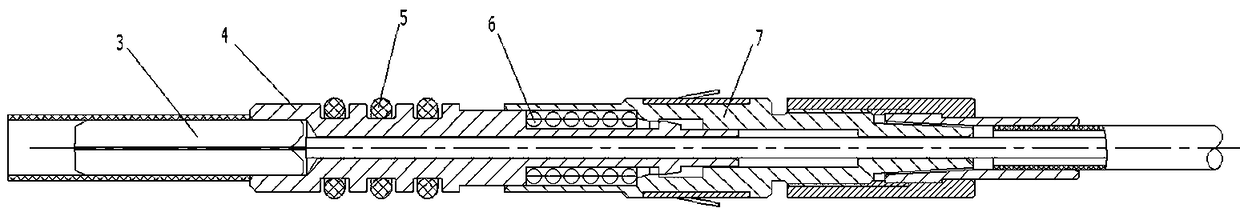

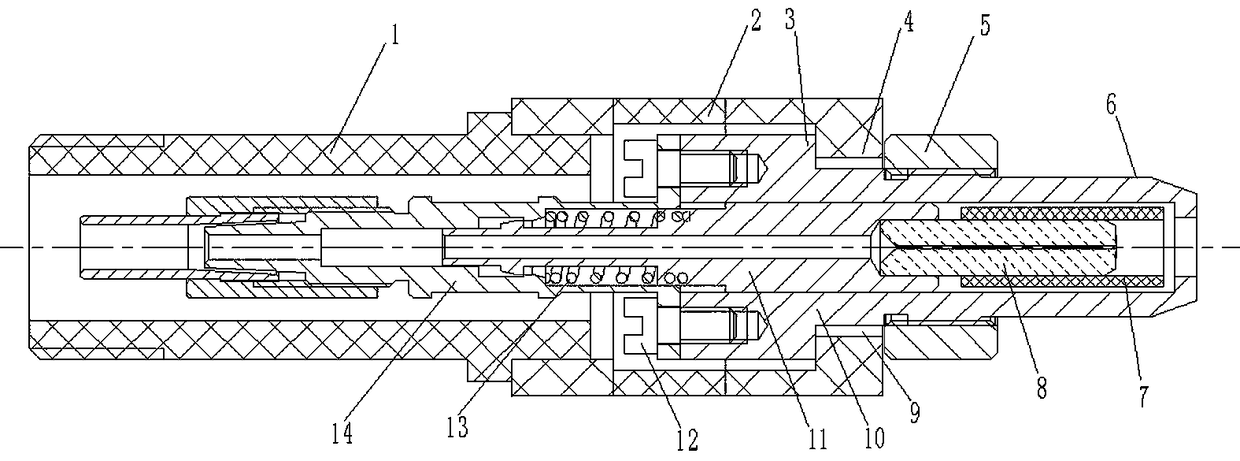

[0022] Examples of optical fiber connector components Figure 3~4 As shown: the optical fiber connector assembly includes an optical fiber plug and an optical fiber socket extending in the front and rear directions in the insertion direction. The optical fiber plug includes a plug housing 1 and a plug contact set in the plug housing 1, and the optical fiber socket includes a socket housing 16 and A socket contact set in the socket housing 16.

[0023] The plug contact includes a plug contact rear housing 14 and a plug that is floating and assembled on the front end of the plug contact rear housing 14 by a spring 13 to contact the front housing 11, and the plug pins 8 are arranged on the front housing 11 of the plug contact. The front end of the pin 8 is fixedly sleeved with a ceramic sleeve 7. The plug pin 8 can be floated in the front and rear direction with the plug contact front housing 11 through the setting of the spring 13, and the floating stroke of the plug contact front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com