How to fix graphics

A pattern and to-be-repaired technology, which is applied in the field of correction of the key dimensions of the mask pattern and the field of correction patterns, can solve the problems such as the inability to guarantee that the key dimensions of the mask can meet the predetermined value range, the success rate is low, and the scrapping and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

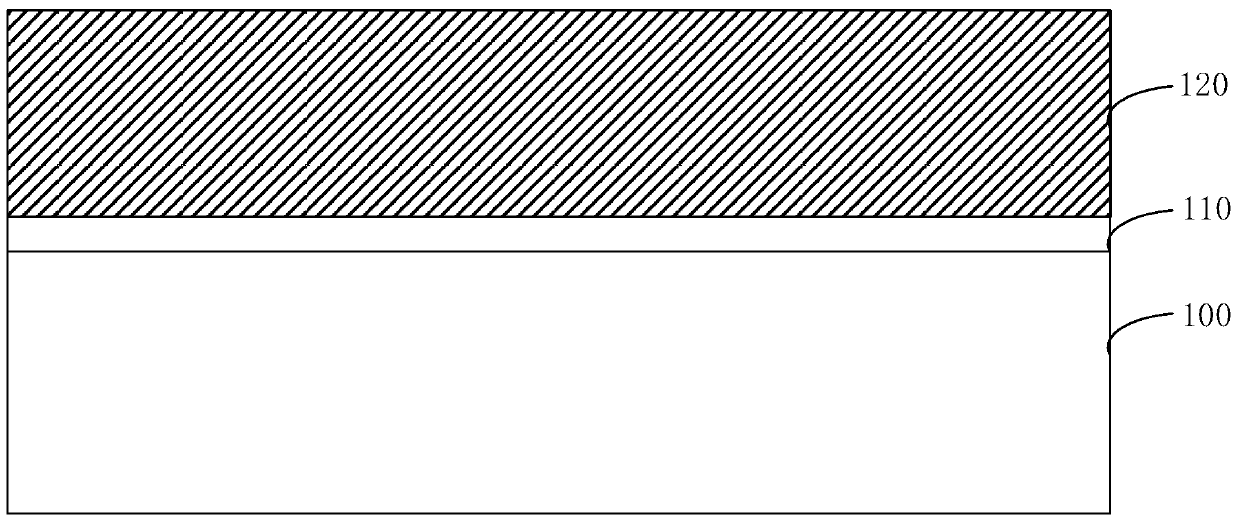

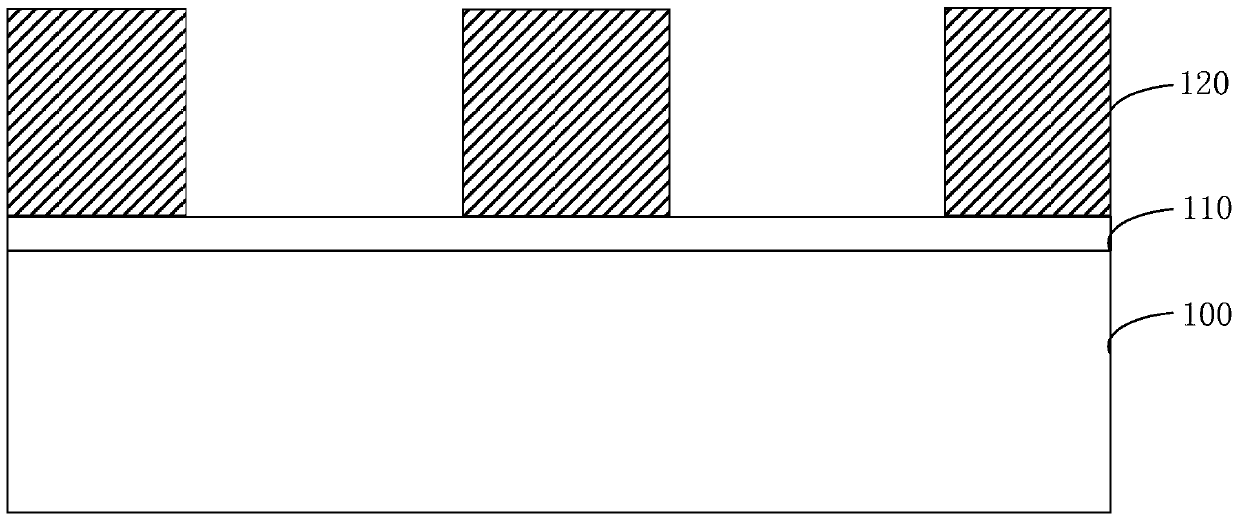

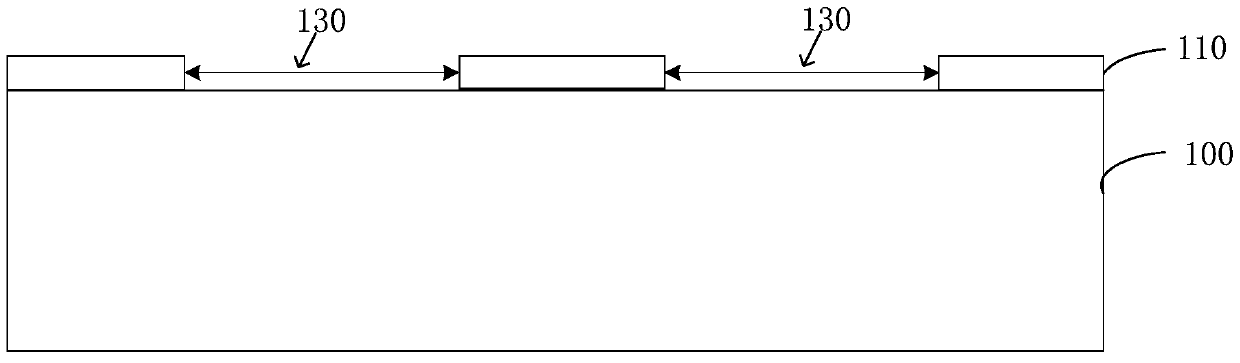

[0036] It can be seen from the background art that, in the process of manufacturing the mask, if the critical dimension of the pattern does not meet the predetermined value range, the mask will generally be reworked. Coating a photoresist layer on the mask plate to be reworked, and then through the processes of alignment, exposure, development, etching, and glue removal, a pattern that meets the predetermined value range of critical dimensions is obtained. However, due to the existing exposure technology, it is impossible to completely align the pattern to be etched with the pattern previously formed on the mask plate, so the success rate of rework is extremely low.

[0037] In order to solve the problem of low success rate of rework caused by low alignment accuracy, the inventors of the present invention conducted further research on the exposure process, and found that the graphic data converted from the standard source data of geometric data is not needed, and the exposure b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com