Aligning method of unmarked deep-anaglyph micro lens array and detector

A technology of microlens array and deep relief, which is applied in the direction of lens, instrument, photoplate making process of pattern surface, etc. It can solve the problem that the deep relief microlens array cannot be aligned with high precision of visible light or infrared detector.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

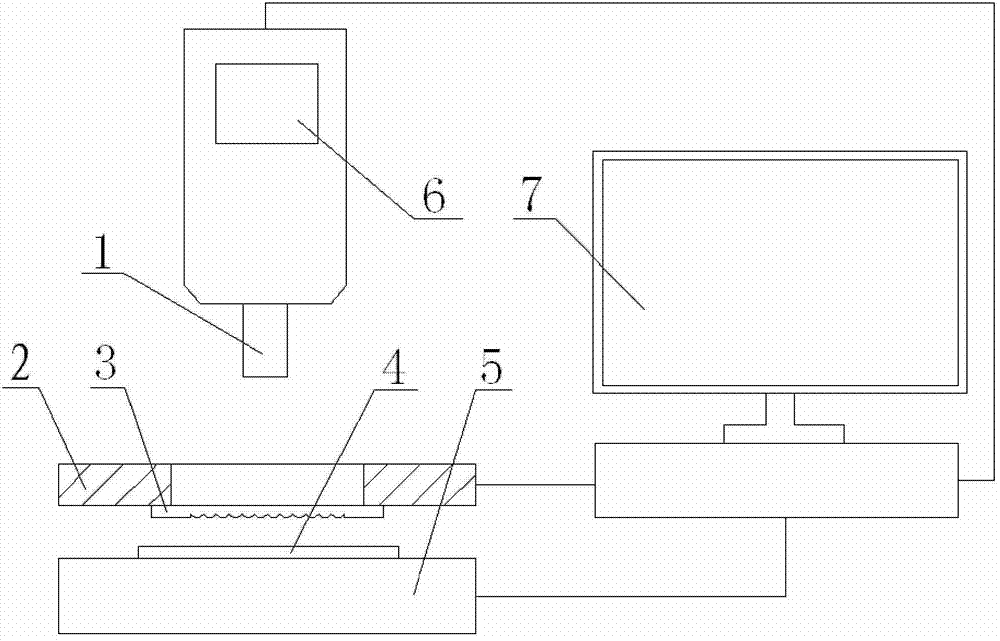

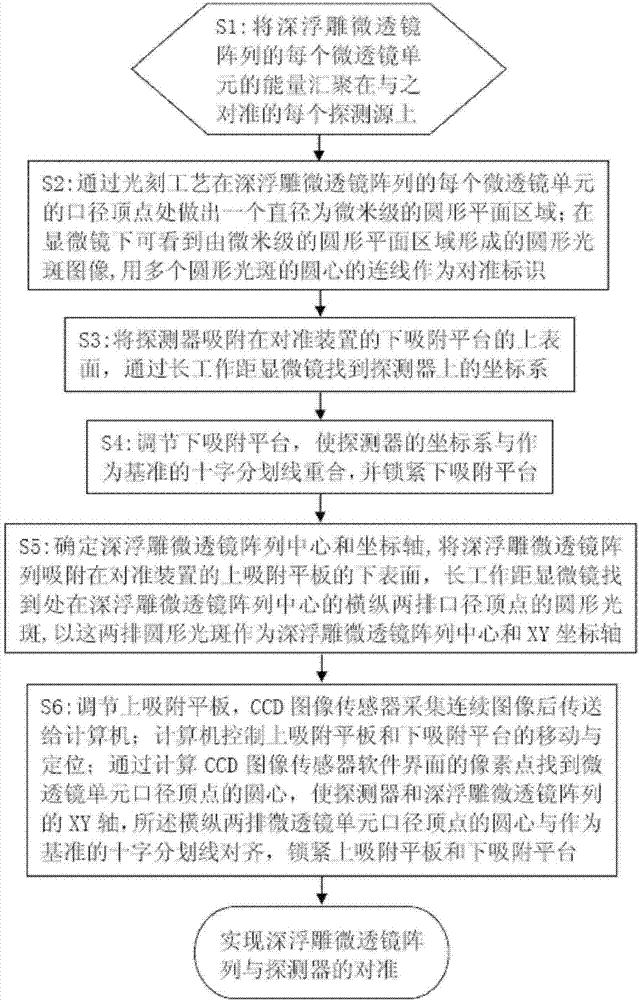

[0048] Embodiment 1: If the alignment accuracy of the deep-relief microlens array and the detector is required to be 0.001 mm, the specific alignment scheme is as follows:

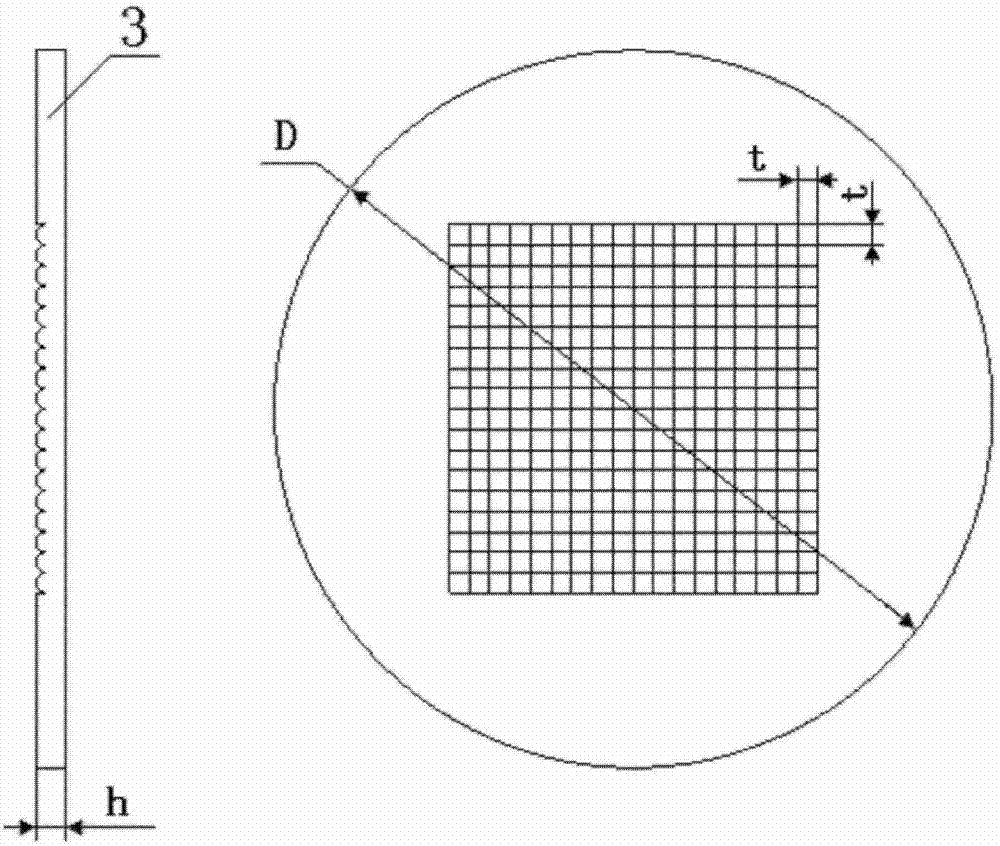

[0049] 1) if figure 2 The deep relief microlens array structure is shown, and the deep relief microlens array 3 is adopted. The deep relief microlens array 3 is composed of 18×18 microlens units 31, and each microlens unit 31 is a convex spherical surface, a square aperture, and a relief The depth is 20 μm, wherein the diameter side length of the microlens unit is t=0.3mm, the outer diameter of the deep-relief microlens array substrate is D=11mm, and the thickness of the deep-relief microlens array substrate is h=0.6mm; the deep-relief microlens array 3 can be with Figure 4 The square caliber used among the shown present invention is a * a=0.26mm * 0.26mm (wherein a is 41 caliber side lengths of detection source), the spacing b=0.08mm of each detection source 41, and detection source 41 quantity is 18 *...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com