Cable protective belt and manufacturing method thereof

A protective belt and cable technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of easy aging, cumbersome operation, waste of materials, etc., and achieve improved heat resistance and heat insulation performance, simple construction and operation, and improved normative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

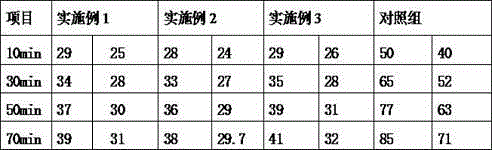

Embodiment 1

[0024] A cable protective belt comprises, from bottom to top, an insulating layer, an elastic rubber pad, a reinforcing layer, an inner protective layer and an outer protective layer.

[0025] The lower surface of the insulating layer is coated with glue, and the upper surface is bonded with an elastic rubber cushion through the glue. The upper surface of the rubber cushion is provided with a reinforcement layer, and the reinforcement layer includes copper wire mesh belt and copper fiber. The upper surface of the reinforcing layer is provided with an inner protective layer, and the interior of the inner protective layer is provided with uniformly distributed cavities, and the outer surface of the inner protective layer is bonded with the outer protective layer by glue, and the glue is rubber glue. adhesive.

[0026] The inner protective layer is made of the following raw materials in parts by weight: 100 parts of silicone rubber, 20 parts of butyl rubber, 2 parts of vulcanizin...

Embodiment 2

[0039] A cable protective belt comprises, from bottom to top, an insulating layer, an elastic rubber pad, a reinforcing layer, an inner protective layer and an outer protective layer.

[0040] The lower surface of the insulating layer is coated with glue, and the upper surface is bonded with an elastic rubber cushion through the glue. The upper surface of the rubber cushion is provided with a reinforcement layer, and the reinforcement layer includes copper wire mesh belt and copper fiber , the upper surface of the reinforcement layer is provided with an inner protective layer, the inner protective layer is provided with uniformly distributed cavities, the outer surface of the inner protective layer is bonded with the outer protective layer by glue, and the glue is rubber Use adhesive.

[0041] The inner protective layer is made of the following raw materials in parts by weight: 100 parts of silicone rubber, 25 parts of butyl rubber, 2.5 parts of vulcanizing agent, 0.7 parts of...

Embodiment 3

[0053] A cable protective belt comprises, from bottom to top, an insulating layer, an elastic rubber pad, a reinforcing layer, an inner protective layer and an outer protective layer.

[0054] The lower surface of the insulating layer is coated with glue, and the upper surface is bonded with an elastic rubber cushion through the glue. The upper surface of the rubber cushion is provided with a reinforcement layer, and the reinforcement layer includes copper wire mesh belt and copper fiber , the upper surface of the reinforcement layer is provided with an inner protective layer, the inner protective layer is provided with uniformly distributed cavities, the outer surface of the inner protective layer is bonded with the outer protective layer by glue, and the glue is rubber Use adhesive.

[0055] The inner protective layer is made of the following raw materials in parts by weight: 100 parts of silicone rubber, 30 parts of butyl rubber, 3 parts of vulcanizing agent, 1 part of acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com