High-efficiency wire stripping tool structure

A wire stripping tool and high-efficiency technology, which is applied in the direction of disassembling/armoring cable equipment, etc., can solve the problems of low efficiency and increase the labor load of workers, and achieve the effect of improving versatility, improving stripping efficiency, and recycling metal wire cores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

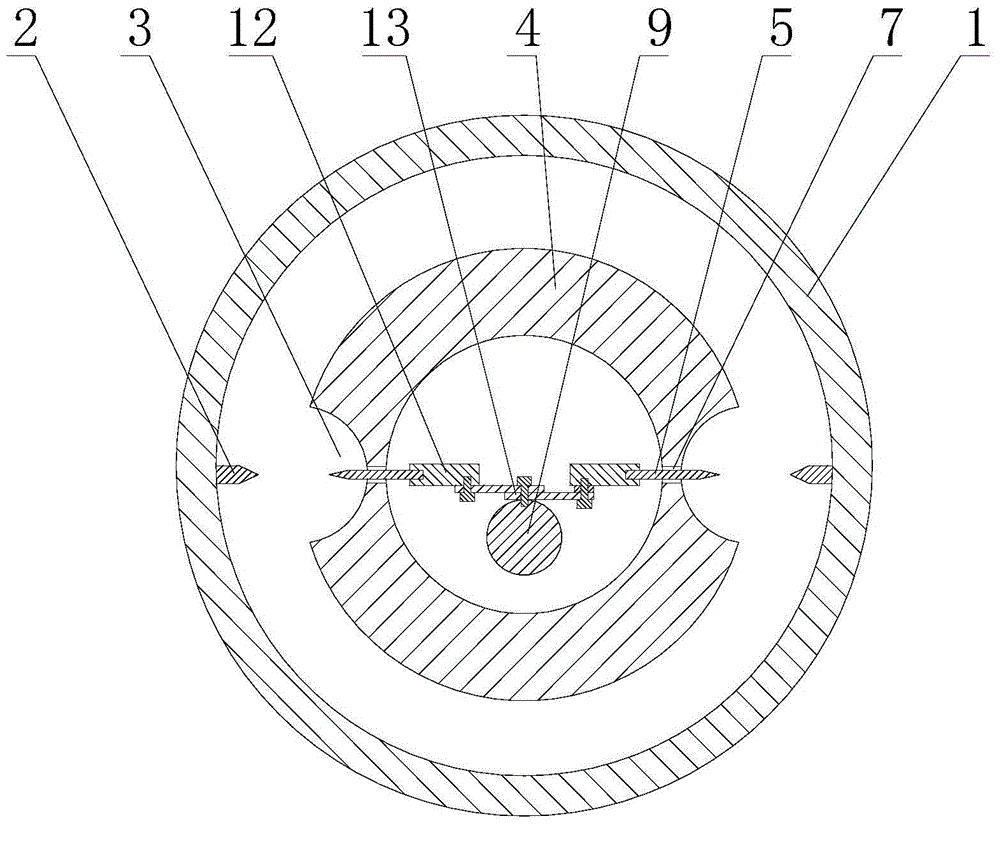

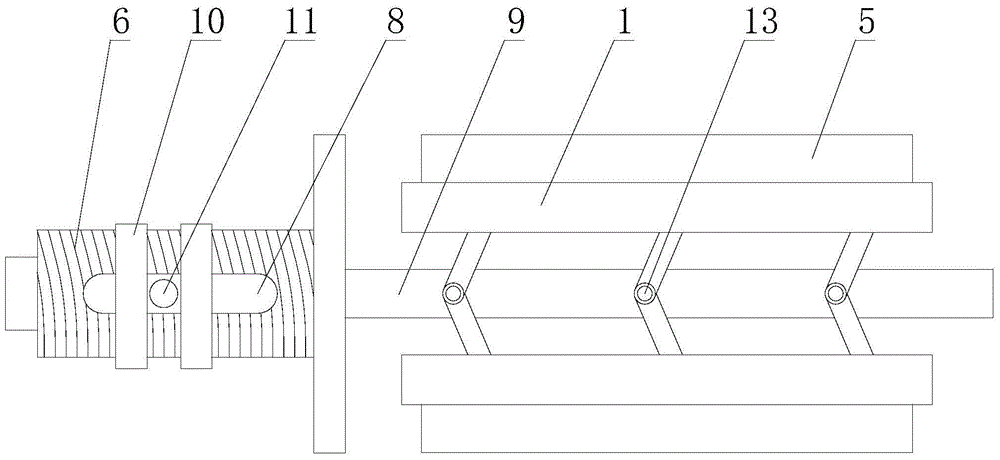

[0021] Such as Figure 1 to Figure 2 As shown, the high-efficiency wire stripping tool structure includes a horizontally arranged inner cutting cylinder 4, a knife holder 12 and a connecting assembly 13, and the outer peripheral wall of the inner cutting cylinder 4 is axially recessed to form two symmetrically arranged positioning recesses. Groove 3, the front end of inner cutting cylinder 4 is fixedly connected with the adjustment cylinder 6 that horizontally arranges, and the outer wall of adjustment cylinder 6 is provided with screw thread and has the bar-shaped opening 8 that runs through its inner and outer walls, also includes two can be connected with adjustment cylinder 6 The ring regulator 10 that is threaded on the outer wall and the movable rod 9 whose diameter matches the inner diameter of the regulating cylinder 6, the end of the movable rod 9 passes through the regulating cylinder 6 and is positioned in the inner cutting cylinder 4, and its front end is positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com