BUCK constant voltage control circuit

A constant voltage control and circuit technology, applied in the circuit field, can solve problems such as poor chip load regulation, high solution cost, and relatively large output voltage differences, and achieve the effect of improving load regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings.

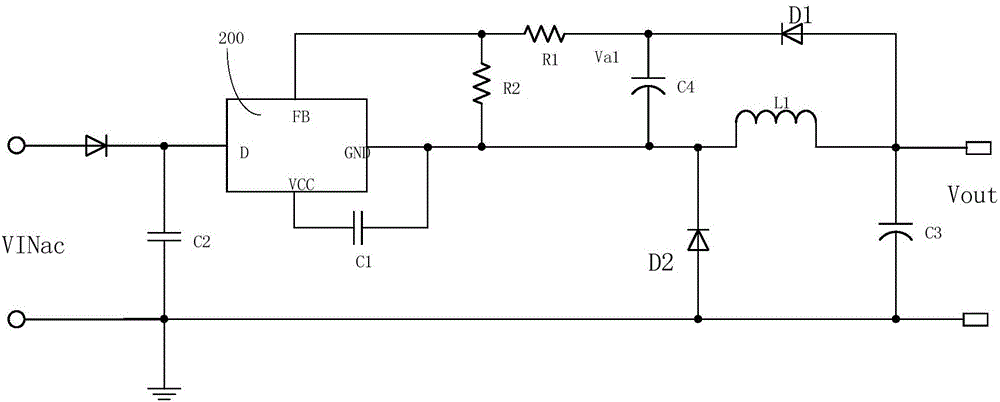

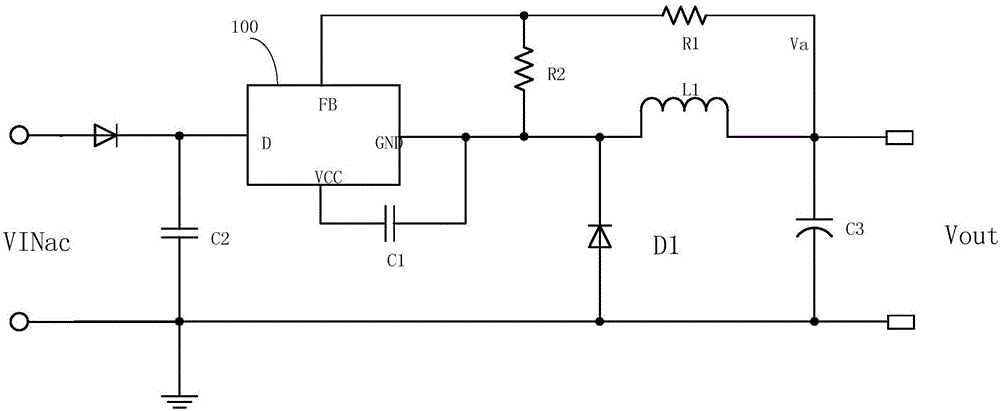

[0018] Such as image 3 As shown, the BUCK constant voltage control circuit of the present invention includes a rectifier diode D2, a control chip 100, a filter capacitor C1, a sampling resistor R1, a sampling resistor R2, an inductor L1, a freewheeling diode D1, and a capacitor C3;

[0019] Among them, such as Figure 5 As shown, the control chip 100 includes a sampling module 101, an EA module 102, an off-time control module 103, a drive unit 104, a main power switch tube Q105 and other control modules 106;

[0020] Such as image 3 As shown, the cathode of the rectifier diode D2 is connected to one end of the input capacitor C2 and the drain end of the control chip 100 ( image 3 Terminal D in the rectifier diode D2), the anode of the rectifier diode D2 and the other terminal of the input capacitor C2 are used to connect the input voltage VINac, and the other terminal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com