Workpiece steering device and glass processing device provided with same

A steering device and workpiece technology, applied in lighting and heating equipment, furnace components, conveyor objects, etc., can solve the problems of high production cost and difficult production of glass processing equipment, and achieve the effect of reducing production difficulty and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

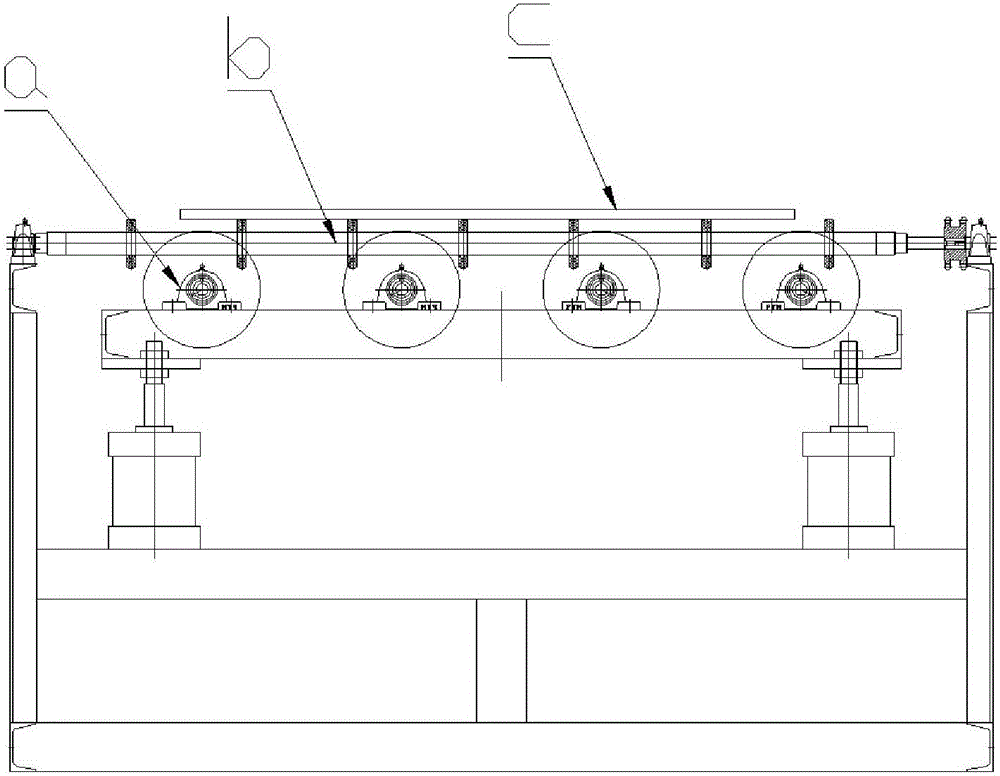

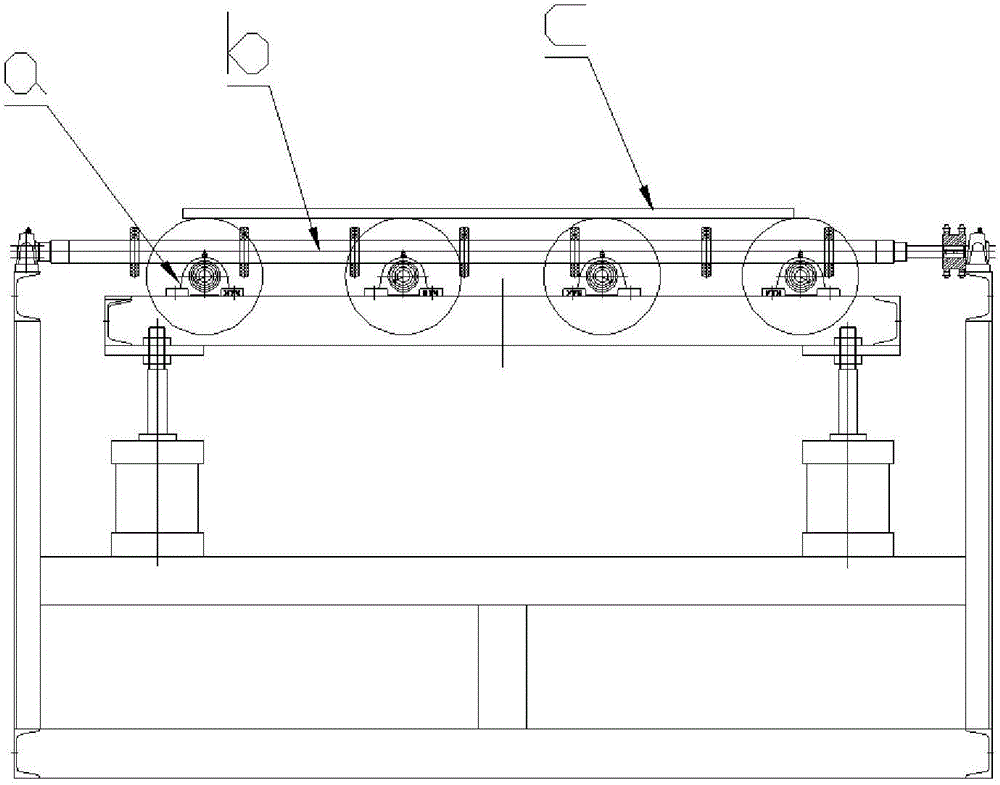

[0029] Such as Figure 4-6 As shown, the workpiece steering device in this embodiment includes a chassis assembly 1 and a workpiece transportation assembly 2, and also includes a steering assembly 3, and the workpiece transportation assembly 2 is rotationally connected to the chassis assembly 1 through the steering assembly 3. By setting the steering assembly 3, the workpiece transport assembly 2 can be turned on the chassis assembly 1, so as to achieve the purpose of turning the workpiece. After the workpiece is turned, the width direction of the workpiece remains unchanged, so there is no need to increase the width of the steering rack. Therefore, the width dimension and production difficulty of the steering rear frame and the steering front frame are the same, and the production cost will not be increased, and problems such as technical bottlenecks will not occur. The workpiece transportation assembly 2 is used to transfer the workpiece between the steering front frame and...

Embodiment 2

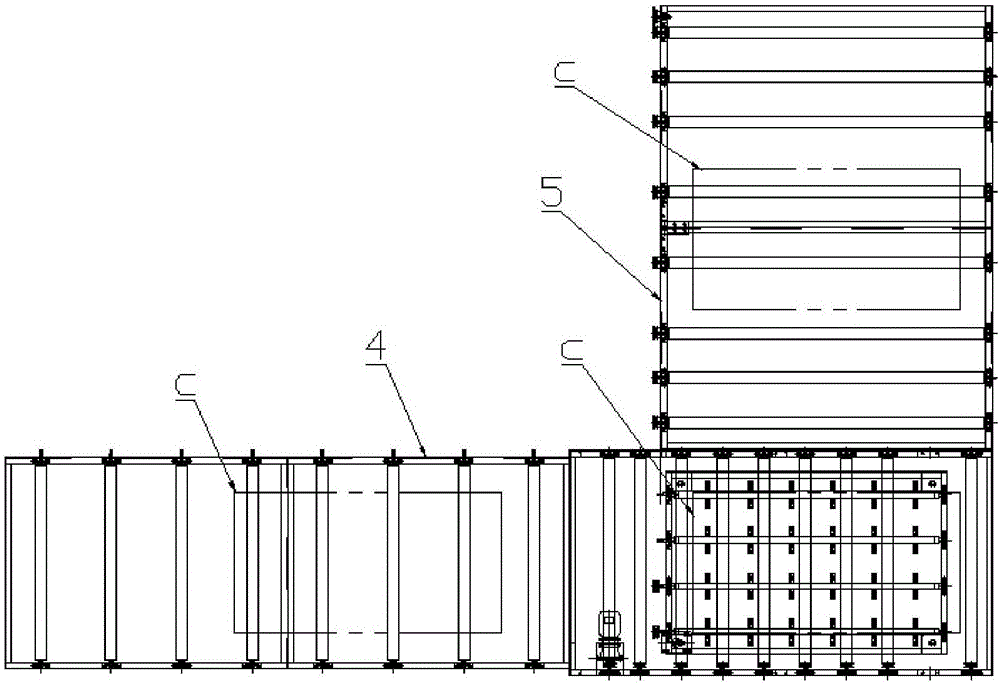

[0034] Such as Figure 4-10As shown, this embodiment provides a kind of glass processing equipment, including the steering front frame 4 arranged along the first direction and the steering rear frame 5 arranged along the second direction different from the first direction, and also includes the workpiece described in the first embodiment A steering device, the workpiece steering device is arranged between the steering front frame 4 and the steering rear frame 5 . According to the workshop space or other usage requirements, the first direction and the second direction may be directions perpendicular to each other, or other directions forming an included angle (not an included angle of 180 degrees) with each other. After the angle between the steering front frame 4 and the steering rear frame 5 is determined, the rotation angle of the workpiece steering device can be set to be the same as the angle between the steering front frame 4 and the steering rear frame 5 . When the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com