Vibration resistant aluminum electrolytic capacitor

An aluminum electrolytic capacitor, anti-vibration technology, applied in the direction of liquid electrolytic capacitors, capacitor parts, capacitor casing/packaging, etc., can solve the problems of positive and negative short circuit, capacitor failure, unstable performance, etc., to overcome easy loosening and improve efficiency , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

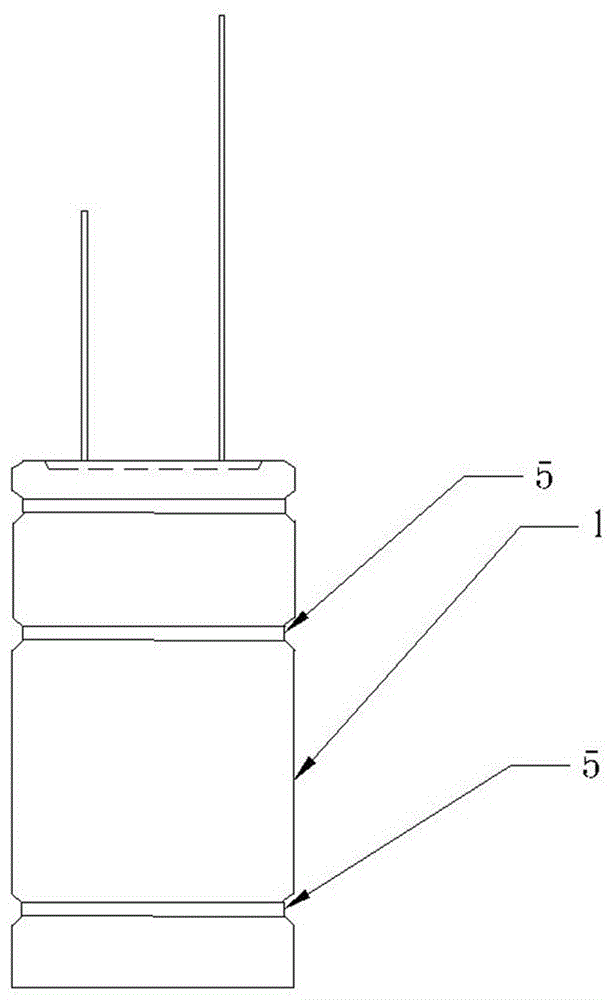

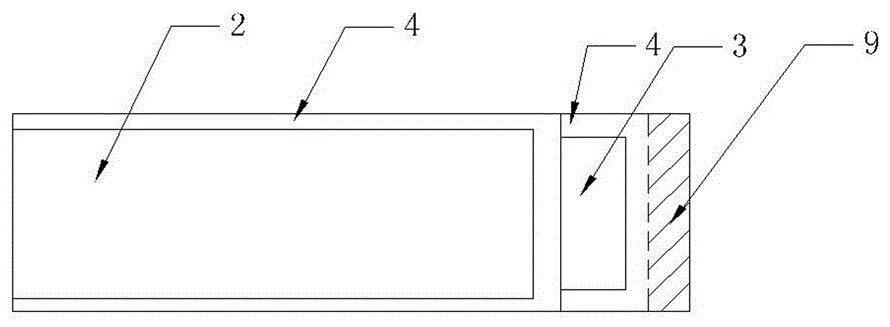

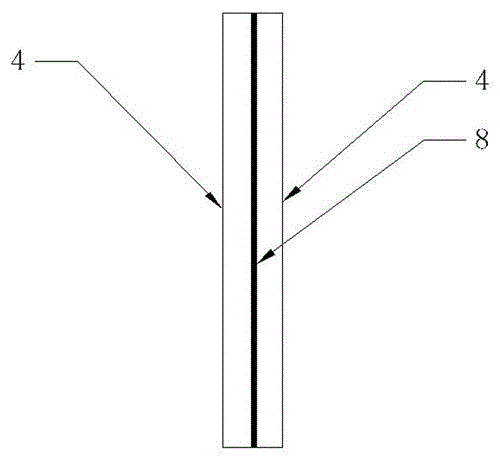

[0032] Such as Figure 1-Figure 3 A vibration-resistant aluminum electrolytic capacitor shown includes a core package 10 and a casing 1, the core package 10 is sealed in the casing 1; the casing 1 is provided with an inner concave groove for fixing the core package 10; the width of the positive electrode foil 2 is wider than that of the negative electrode The width of the foil 3, the winding starting ends of the positive electrode foil 2, the negative electrode foil 3 and the electrolytic paper 4. The positive electrode foil 2 is longer than the negative electrode foil 3, and the two side edges of the negative electrode foil 3 are located inside the two side edges of the positive electrode foil 2. The inner concave groove is a circular element girdle 5, the element girdle 5 is a single-turn element girdle or a multi-turn element girdle, and the multi-turn element girdle is evenly arranged on the shell 1.

[0033] In this embodiment, the positive electrode foil 2 is 0.5-3mm wid...

Embodiment 2

[0042] In this example, if Figure 4 and Figure 5 The inner concave groove shown is a vertical groove 6 , and a plurality of vertical grooves 6 are uniformly arranged on the shell 1 . Other parts are identical with embodiment 1.

Embodiment 3

[0044] Such as Figure 6 and Figure 7The shown inner concave groove is a dot-shaped groove 7; a plurality of dot-shaped grooves 7 are uniformly arranged on the shell 1. Other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com