A milling tool

一种铣刀、切削刀片的技术,应用在铣刀、铣削切削刀片、切削刀片等方向,能够解决切削刀片更换繁琐且费时、转位工作费时等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

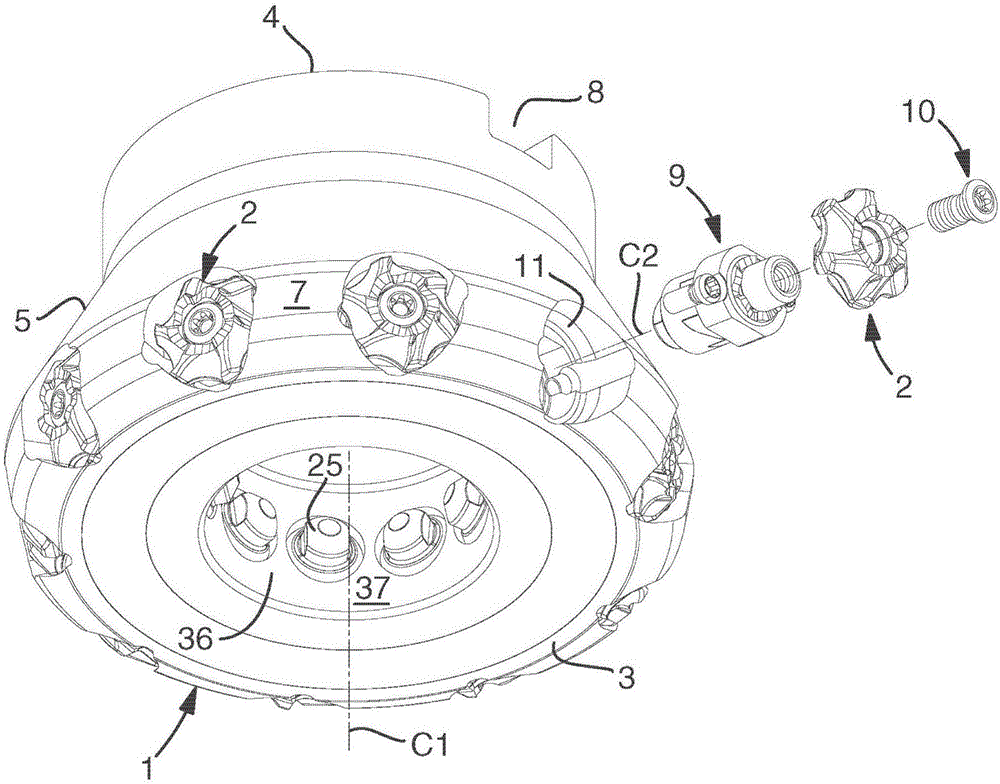

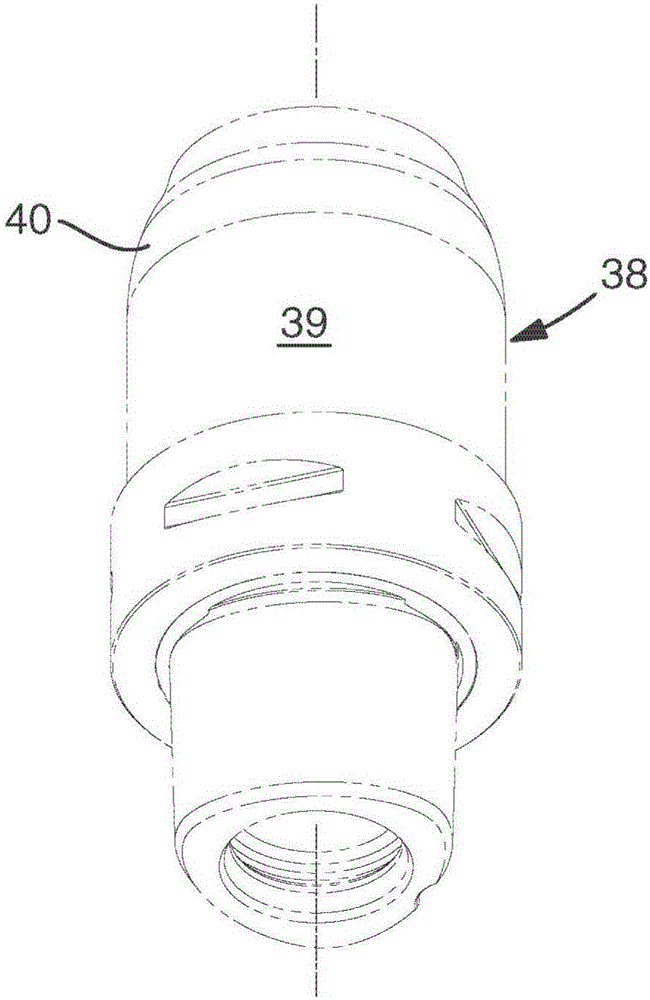

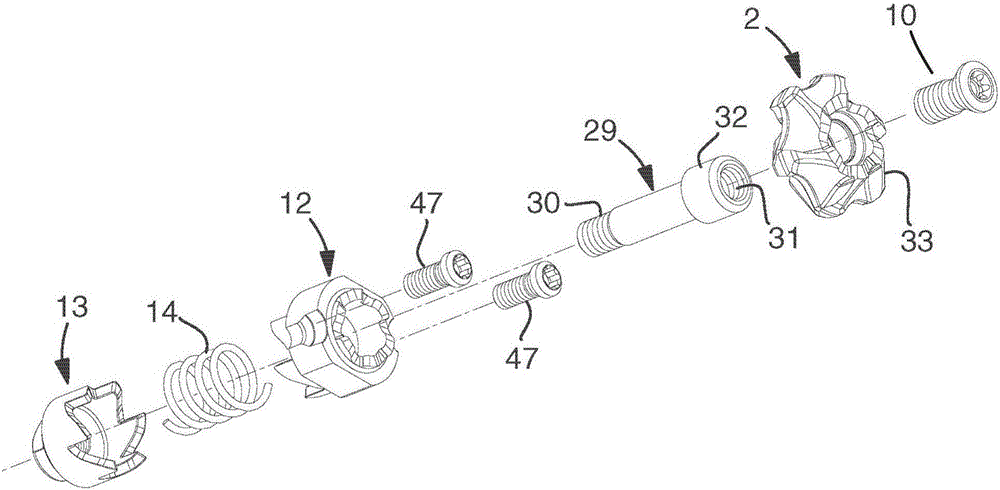

[0032] In the figures, a cutting tool made according to the invention is shown in the form of a face mill or end mill. In the tool there is comprised a body or body generally designated 1 which houses a plurality of replaceable cutting inserts 2 . Body 1 includes a pair of opposite fronts 3 and backs 4 (see figure 1 and 9) and an envelope surface 5 located between the front side 3 and the rear side 4 and having a circular rotationally symmetrical shape. The front side 3, the envelope side 5 and the back side 4 are contained in the outer side of the body. The back face 4 is a flat annular surface. The front face 3 is also a flat annular surface, which in this example extends perpendicular to the central axis C1 on which the body is rotatable. Surfaces 3 and 4 are parallel to each other and also to the reference plane RP, which at Figure 9 shown in . It should additionally be noted that the surface of revolution forming the envelope surface 5 is generated on the central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com