Rack guide and rack-and-pinion steering device provided with same rack guide

A technology of guides and pinions, applied in the direction of elements with teeth, belts/chains/gears, hoisting devices, etc., can solve problems such as increased collision noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A more detailed description of the manner of carrying out the invention will be given below with reference to a preferred embodiment shown in the accompanying drawings. It should be noted that the present invention is not limited to these Examples.

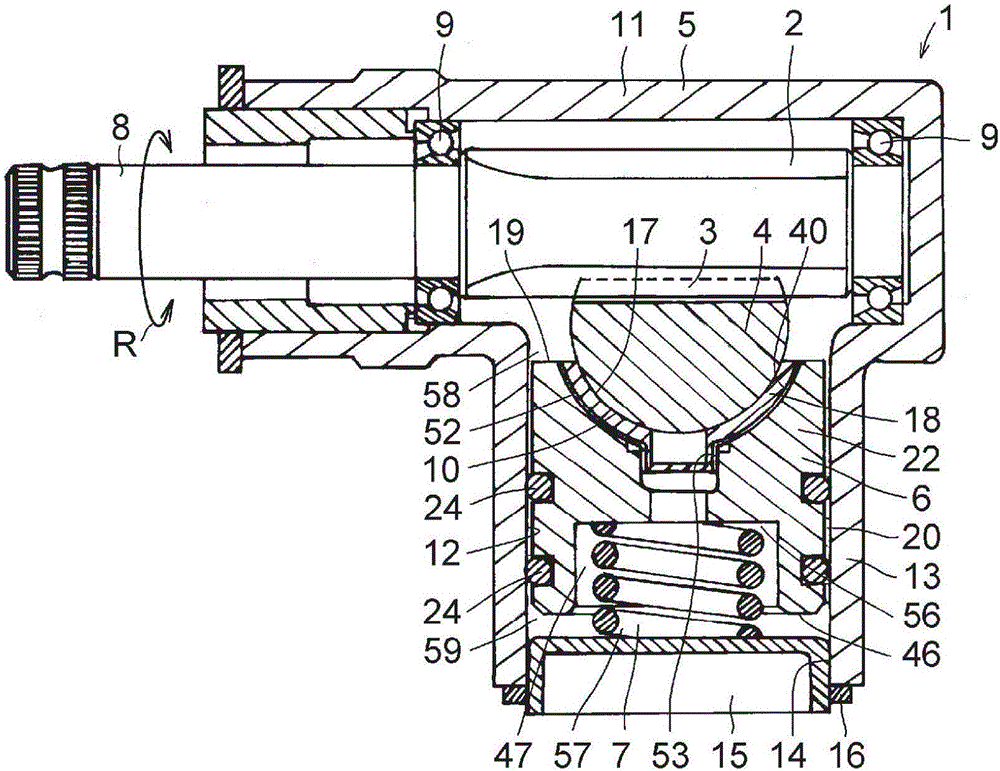

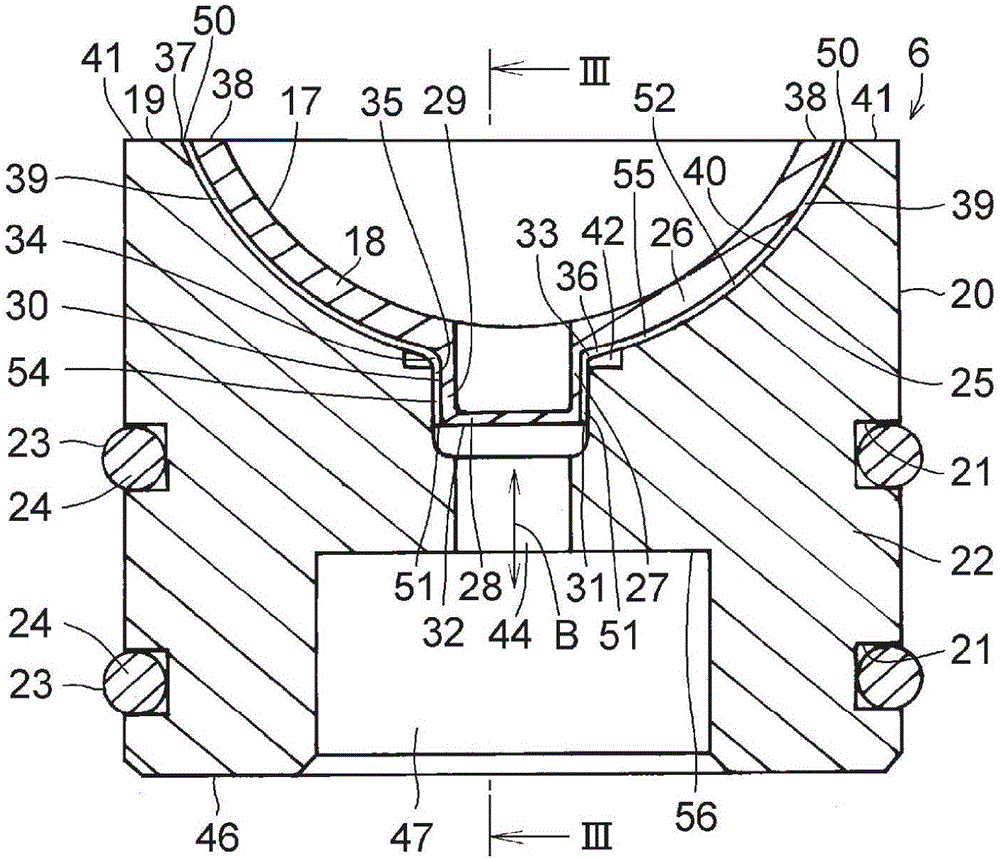

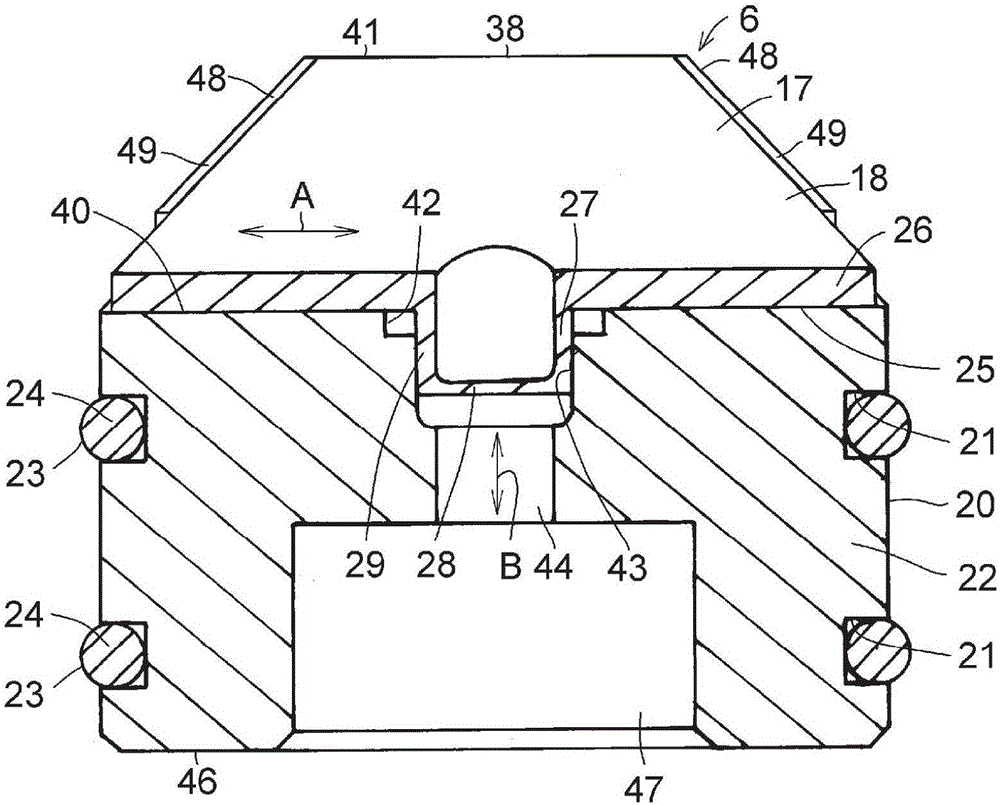

[0036] exist Figures 1 to 10 Among them, the rack and pinion type steering device 1 according to this embodiment includes: a pinion 2 rotating in the R direction; a rack 4 having rack teeth 3 meshing with the pinion A (perpendicular to figure 1 The direction of the plane of the drawing) can be linearly moved; the gear box 5, which supports the pinion 2 rotatably in the R direction; the rack guide 6 for slidably supporting the rack 4; and the elastic device 7, which will The rack guide 6 presses against the pinion 2 .

[0037] The pinion shaft 8 is rotatably supported in the R direction by means of ball bearings 9 in the gear case 5 together with the pinion 2 integrally formed therewith, and is adapted to rotate in the R...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap