Straw smashing, stubble cleaning and rotary cultivation integrated machine

A technology of straw crushing and integrated machine, which is applied to agricultural machinery and tools, shovels, plows, etc., can solve the problems of not being able to return the field directly, not being able to carry out rotary tillage in autumn, and straw polluting the environment, so as to save energy consumption of agricultural machinery and change Good effect of agricultural practice and crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

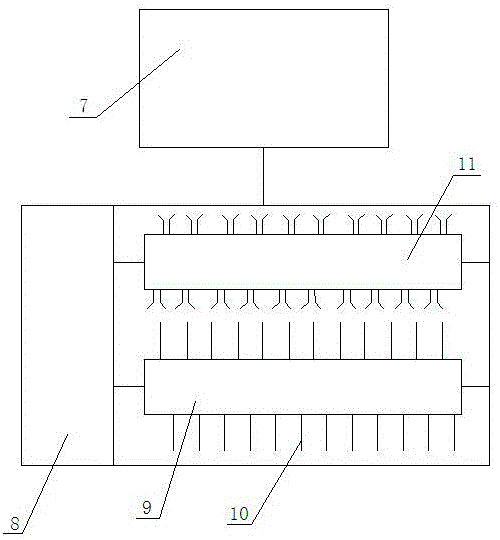

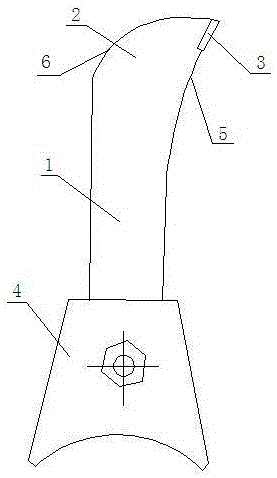

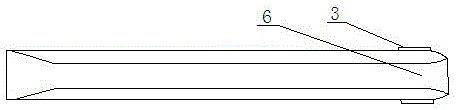

[0018] A straw crushing and stubble removal rotary tillage machine, which consists of: a transmission mechanism 8, the transmission mechanism is respectively connected with the stubble removal rotary shaft 9, and the straw crushing shaft 11, and the stubble removal rotary shaft is installed with a helical wire Arranged alloy cutter head rotary tillage blade 10, the handle of the alloy cutter head rotary tillage blade includes a straight handle body 1 and a curved handle head 2, and the belly side of the handle of the curved handle head is the inner Concave curve type 5, the back side of the knife handle of the curved handle head is a convex curve type 6, and the alloy cutter head 3 is embedded in the belly side end of the knife handle of the curved handle head.

Embodiment 2

[0020] According to the all-in-one machine for crushing and removing stubble and rotary tillage described in Example 1, the thickness of the abdomen side of the knife handle is 1-3 times the thickness of the back side of the knife handle, and the back side of the curved handle head is along the convex curved surface to The end of the curved shank gradually becomes thicker until it is as thick as the belly side of the handle.

Embodiment 3

[0022] According to the straw crushing and stubble removal rotary tillage machine described in embodiment 1 or 2, 5-9 combinations of gold cutter head rotary tillage blades are installed along the stubble removal rotary tillage shaft, and each group of alloy cutter head rotary tillage blades is arranged according to the helical line. Arranged on the described stubble removal rotary tillage shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com