Visual recognition unit applied to vamp head mounting machine

A technology for visual recognition and shoe upper stickers, applied in the field of visual recognition units, can solve the problems of high cost and low production pertinence, and achieve the effect of strong practicability, improved recognition accuracy, and reduced requirements for intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

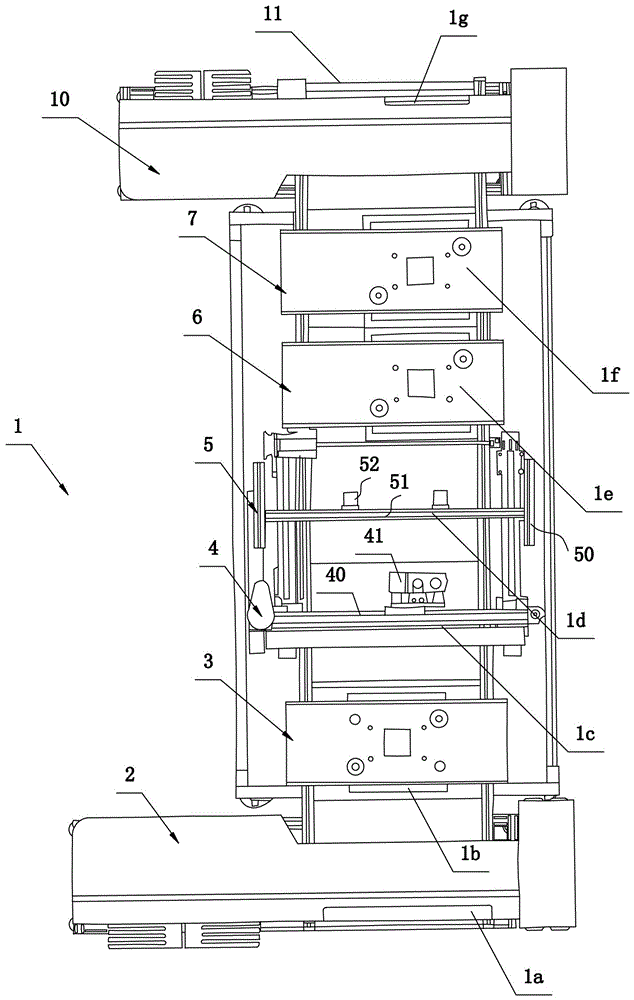

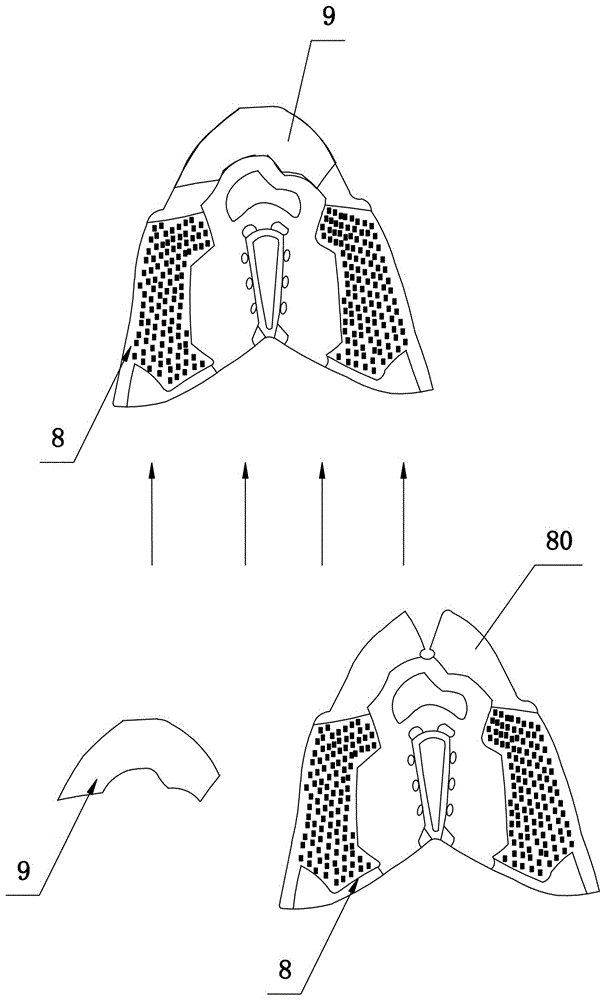

[0018] refer to figure 1 , figure 2 , image 3 and Figure 4 . A structurally improved vamp pasting machine includes a production line 1 arranged in a strip shape, and the production line 1 includes,

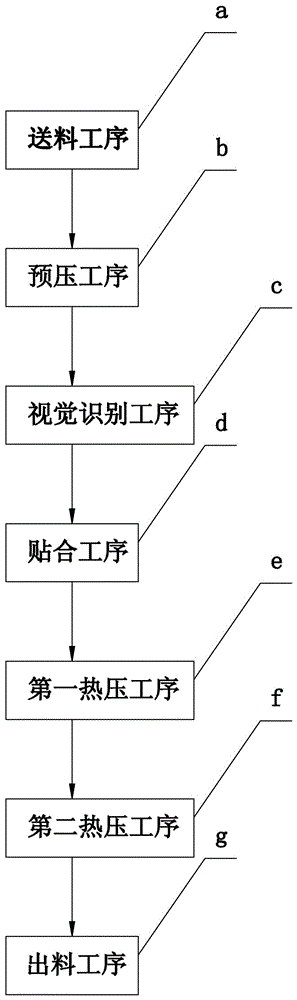

[0019] The sequentially adjacent feeding station 1a, pre-pressing station 1b, visual recognition station 1c, laminating station 1d, first hot-pressing station 1e, second hot-pressing station 1f, and receiving station 1g;

[0020] The automatic feeder 2 located on the side of the feeding station 1a, the pre-pressing machine 3 located above the pre-pressing station 1b, the visual identification unit 4 located above the visual identification station 1c, the laminating unit 4 located above the laminating station 1d Axis module 5, the first hot press 6 located above the first hot press station 1e, the second hot press 7 located above the second hot press s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com