A cargo handling device and its handling method

A technology of handling device and cargo transportation, applied in transportation and packaging, conveyor control device, packaging, etc., can solve problems such as low efficiency and high labor intensity, improve work efficiency, improve automation, and reduce equipment intelligence requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

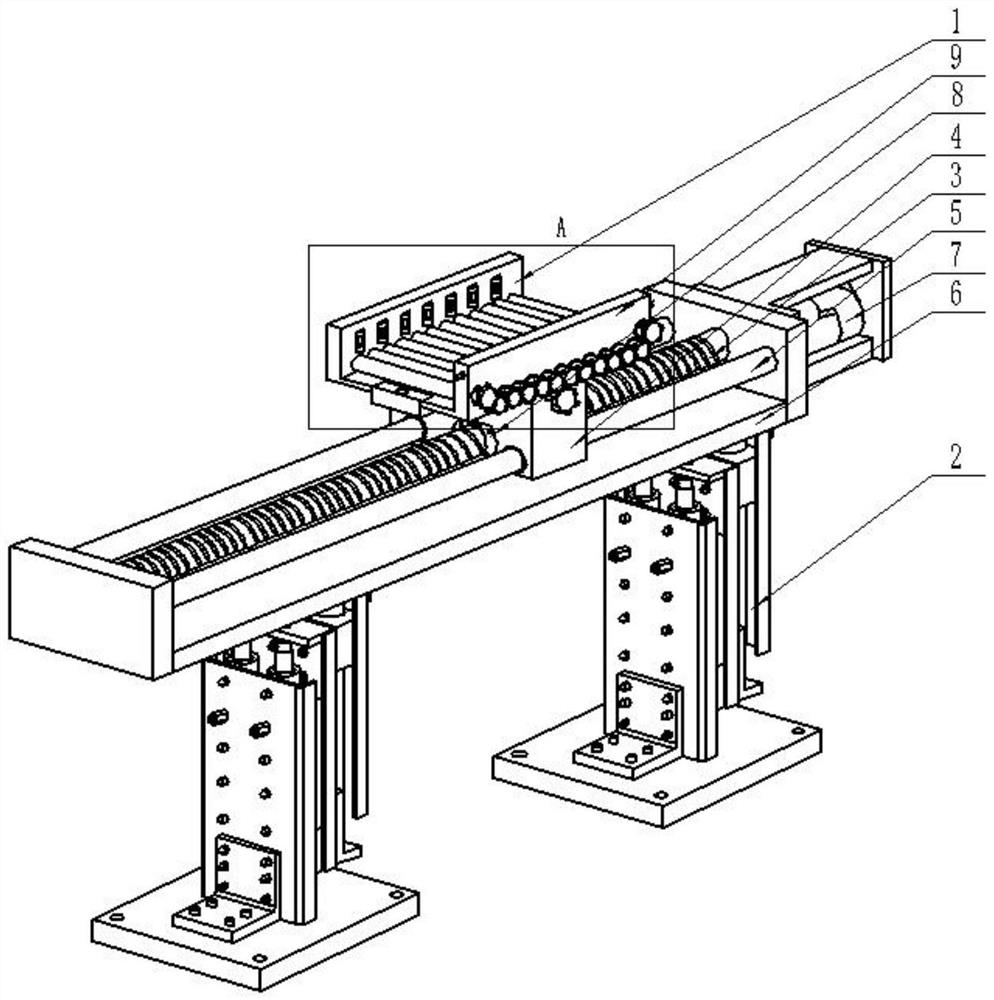

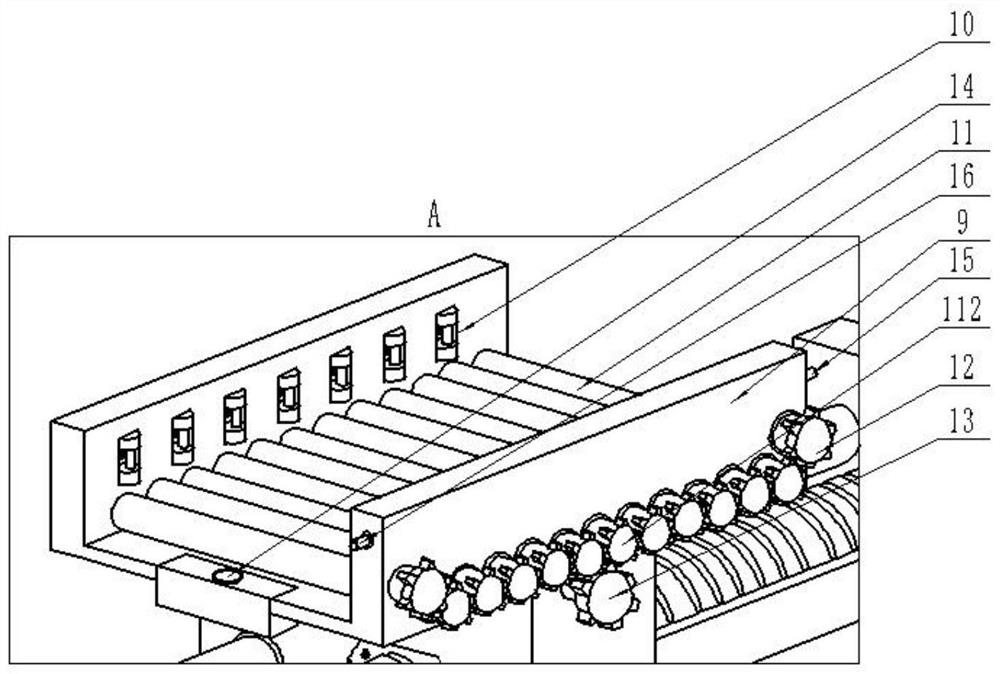

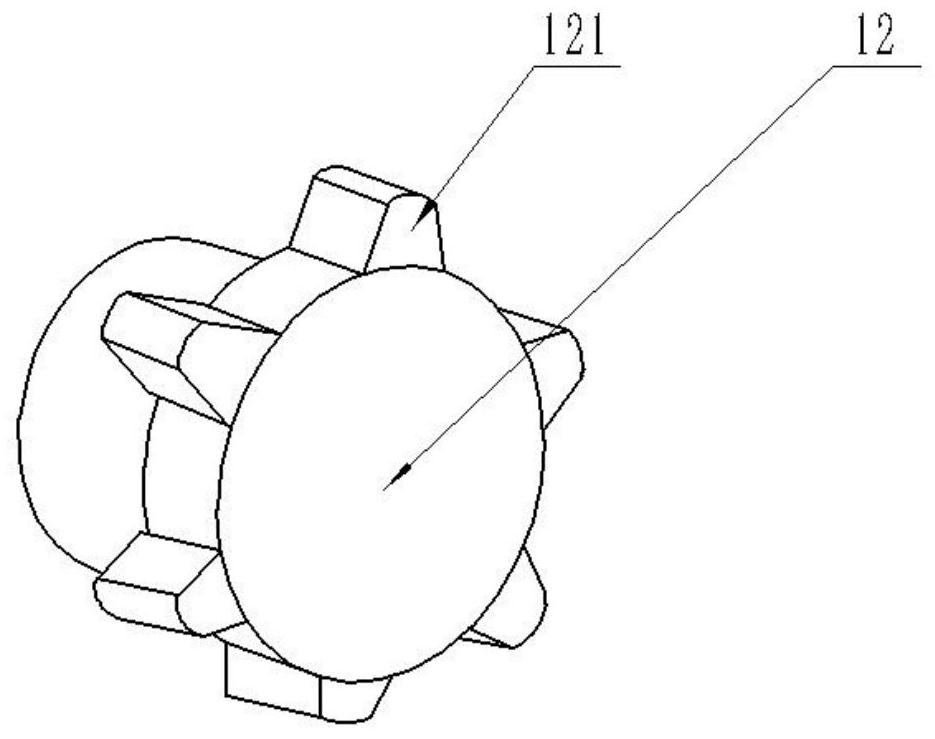

[0111] Such as figure 1 As shown, a cargo handling device includes: a cargo transport platform 1, a moving fast 4 is arranged below; a moving motor 7 includes a power end, and the moving motor 7 is arranged on the right end of the cargo handling device; The component 2 is provided with a moving end; a connecting plate 6 is located between the moving motor 7 and the lifting component 2 .

[0112] The lifting assembly 2 is used to control the moving motor 7 and the cargo transport platform 1 to move up and down, and the mobile motor 7 controls the cargo transport platform 1 to move horizontally. The connecting plate 6 is connected to the moving end of the lifting assembly 2 , the power end of the moving motor 7 is provided with a ball screw 3 , and the surface of the ball screw 3 is threadedly connected with a moving block 4 . Start the moving motor 7, and the ball screw 3 converts the curved motion into a curved motion, and then drives the moving block 4 to perform linear moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com