Air floating water push type rice washing machine

An air-floating water-push type and casing technology is applied in the field of rice washing machines, which can solve the problems such as the inability to automatically discharge the rice, the poor cleaning quality, and the inability to use rice for food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

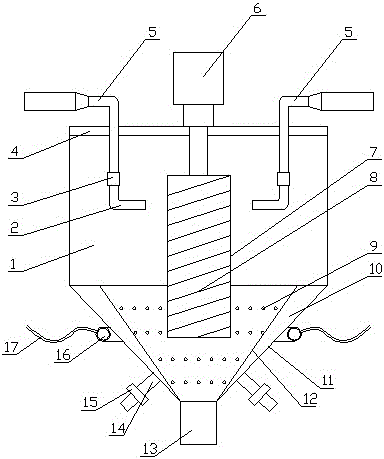

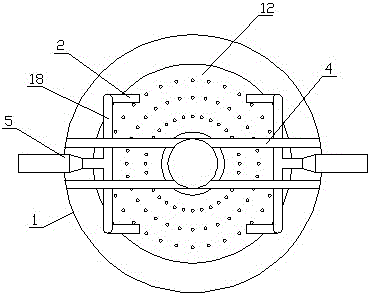

[0017] Such as figure 1 , figure 2 Shown, a kind of air flotation water push type rice cleaning machine, comprises casing 1, mounting frame 4, stirring motor 6, stirring shaft 7, spiral blade 8, movable water spray device, mesh screen type air inlet and water outlet device. The casing 1 is made of food-grade stainless steel plate. The top of the casing 1 is provided with a mounting frame 4. The mounting frame 4 is made of two stainless steel square steel pipes. The two stainless steel square steel pipes are installed side by side on the machine by welding or bolt fastening. Shell 1 top. Stirring motor 6 is installed on the installation frame 4, and the output shaft of described stirring motor 6 is provided with the stirring shaft 7 with helical blade 8, can install reduction box between stirring motor 6 and stirring shaft 7 if necessary. The upper part of the casing 1 is provided with a movable water spray device, and the lower part of the casing 1 is provided with a screen...

Embodiment 2

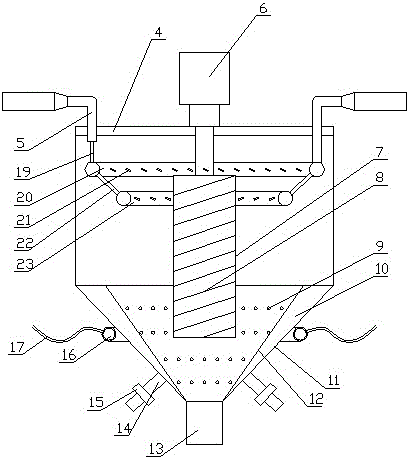

[0022] The structure of this embodiment is mostly the same as that of Embodiment 1, except that the movable water spray device includes a water inlet pipe 5, a vertical connection pipe 19, a first water spray ring pipe 20, an oblique connection Pipe 22, the second water spray ring pipe 23, the water inlet pipe 5 is installed on the top of the casing 1, the lower end of the water inlet pipe 5 is connected with the vertical connecting pipe 19, and the lower end of the vertical connecting pipe 19 is provided with a first Water spray annular pipe 20, described first water spray annular pipe 20 is equipped with oblique connection pipe 22, the other end of described oblique connection pipe 22 is provided with second water spray annular pipe 23, described first water spray The annular pipe 20 and the second water spray annular pipe 23 are all installed on the outer periphery of the stirring shaft 7 and are concentric with the stirring shaft 7, and the inner sides of the first water sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com