Part bending device for electric equipment

A technology for power equipment and bending processing, applied in the field of bending devices, can solve problems such as the use stability of the precision equipment that is not conducive to processing, the flexible deformation of the extension length of the bending execution head, the increase of equipment cost and complexity, etc. The effect of post-maintenance, improving reliability and service life, and reducing equipment complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

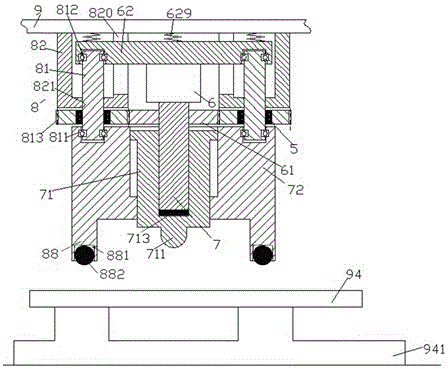

[0007] Combine below figure 1 The present invention will be described in detail.

[0008] The bending processing device for parts for electric equipment according to the embodiment is used for bending processing for parts for electric equipment, including two lifting and pressing assemblies 8 fixedly installed on the upper fixture 9, and the two lifting and pressing assemblies 8 are arranged symmetrically with respect to the longitudinal axis of the bending device and each includes: a threaded sleeve 82 fixed on the upper fixture 9, a driving screw threadedly engaged with the threaded hole 821 in the lower end wall of the threaded sleeve 82 81, and the screw drive gear 813 located under the threaded sleeve 82 and connected with the drive screw 81 through the torque clutch 5, the lower end of the drive screw 81 of each of the two lifting and pressing assemblies 8 passes through the lower end The thrust bearing 811 is connected to the upper side of the workpiece pressing part 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com