A magnetic stress-relieving mounting method for thin planar optical elements

An optical element and stress relief technology, which is applied in the field of the upper plate of the element, can solve the problems of the large surface change of the thin plane element, the difficulty in controlling the height of the adhesive layer, and the technical dependence of the processing personnel. , easy to operate, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

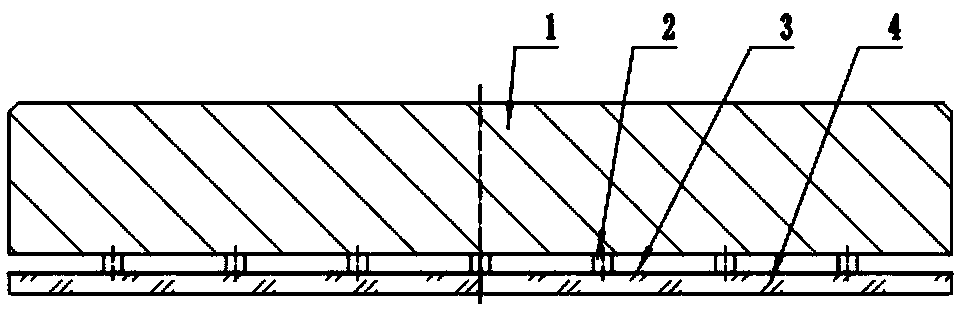

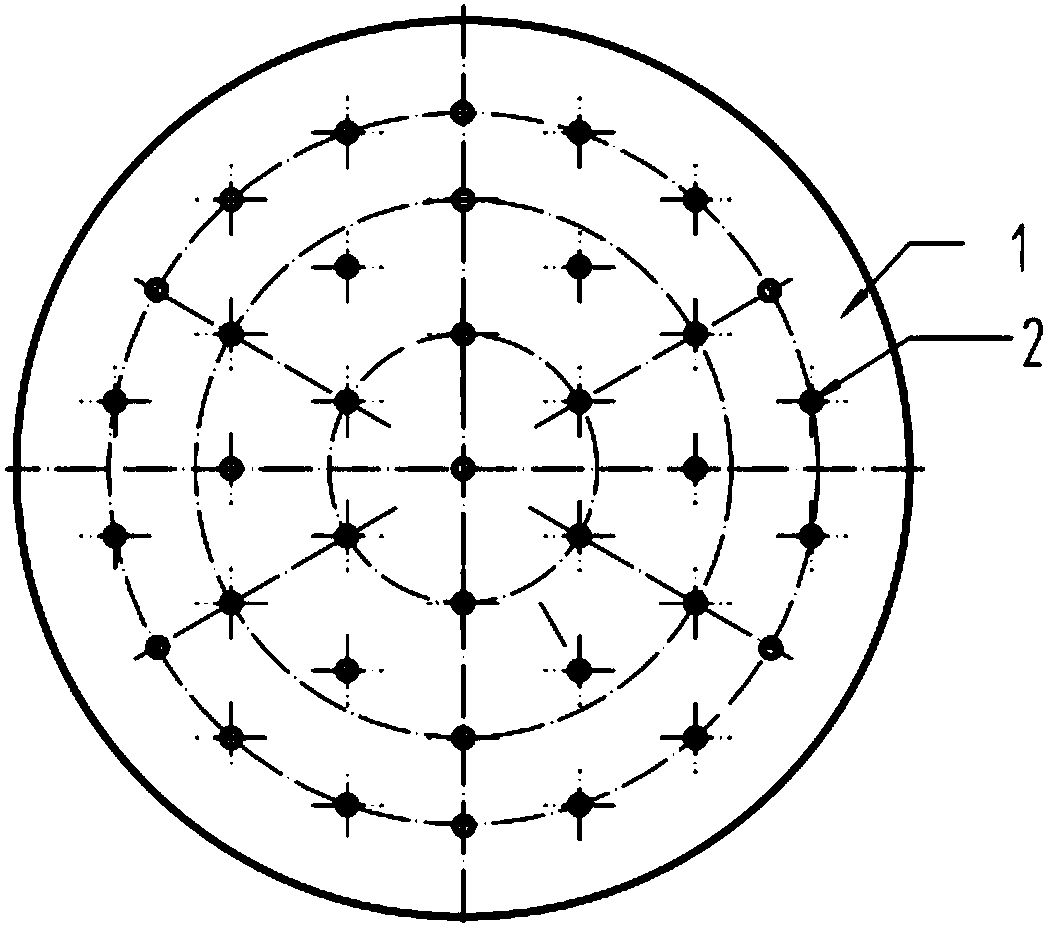

[0026] see first figure 1 , figure 1 It is a rear side view of the magnetic stress-relief optical element of the present invention, and it can be seen from the figure that after the optical element is mounted, it includes an upper plate substrate 1, a magnet block 2, an adhesive film (double-sided adhesive tape) 3 and a thin film from top to bottom. Shaped planar optical element 4.

[0027] The specific processing procedures are as follows:

[0028] Firstly, cover a layer of adhesive film 3 on the surface of the upper plate of the thin planar optical element 4 to be processed, magnetize the processed cylindrical magnet block 2, and place it on the upper plate substrate 1 according to the designed arrangement Paste the cylindrical magnet block 2, put the side of the thin planar optical e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com