A matching welding method for hoisting connection lugs of co-lifting drilling rig

A drilling rig and lug technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of poor welding accuracy of drilling rig and base lifting connection lugs, poor component stress, and on-site operation. Difficulties and other problems, to achieve the effect of reducing the inconsistency of welding benchmarks, reducing welding difficulty, and strong on-site operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] Up, down, left, and right in the text are subject to the orientation shown in the figure, and so on for the actual installation position.

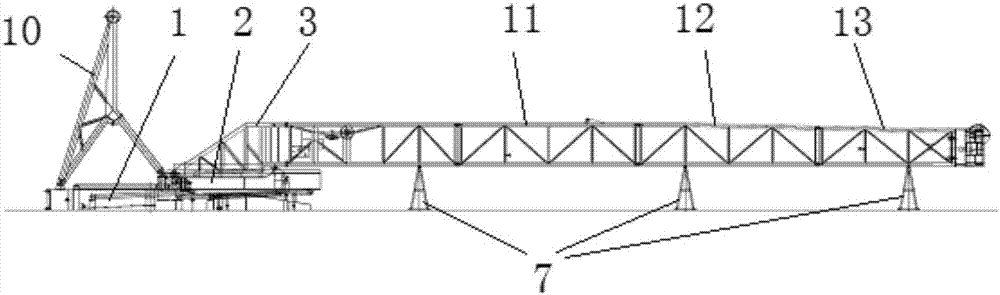

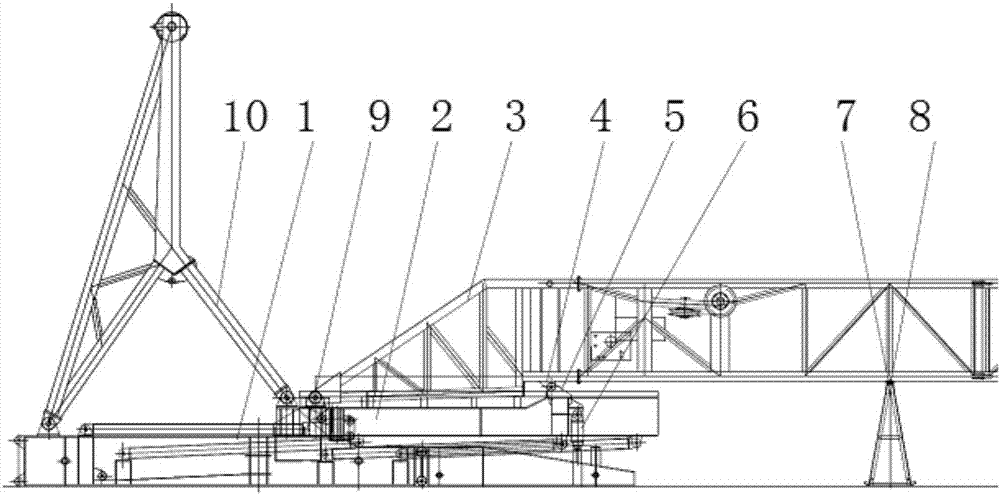

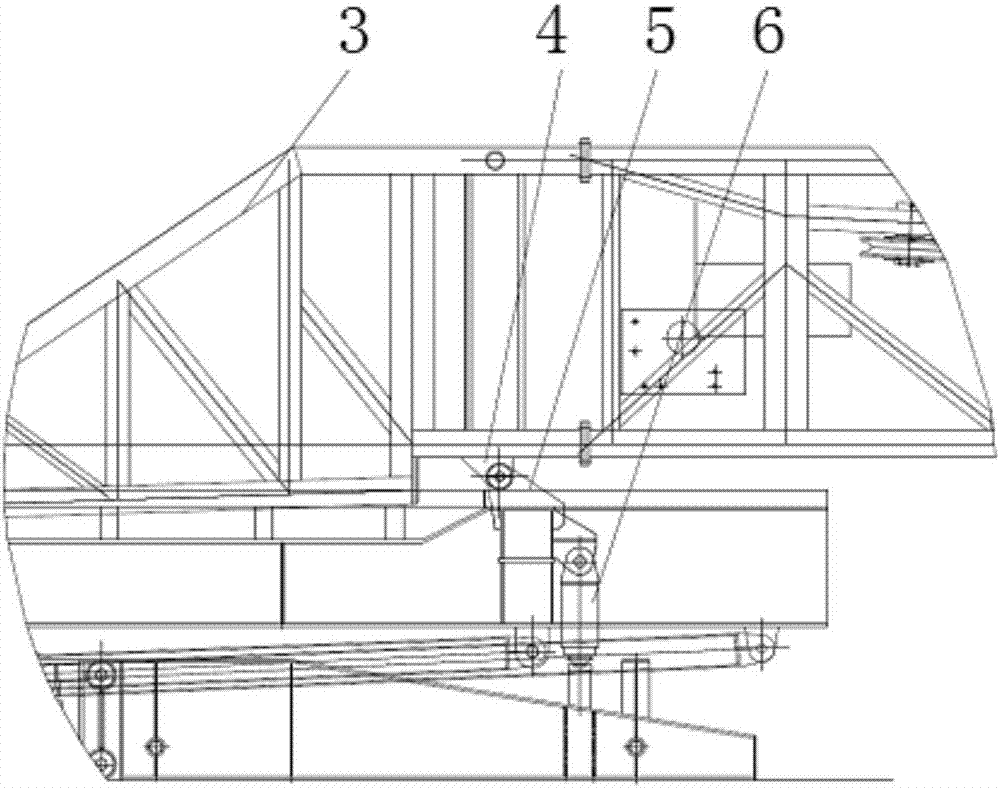

[0022] refer to figure 1 , figure 2 The overall structure of the same-lift drilling rig derrick adopted in the method of the present invention is in a horizontal state, the lower base 1 of the drilling rig is arranged on the cement floor of the drilling rig test well site, and is used to support and install other parts of the drilling rig; A herringbone frame 10 is installed at the end, which is used for lifting of the drilling rig and fixing after lifting; the front end of the lower base 1 of the drilling rig is equipped with the upper base 2 of the drilling rig, and the lower base 1 and the upper base 2 of the drilling rig pass through multiple The column and the inclined frame are connected; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com