A sealed and adsorbed adjustable support device for processing a thin plane of a stem assembly

A support device and adsorption-type technology, which is applied in the direction of metal processing machinery parts, positioning devices, clamping devices, etc., can solve the problems of damaged inner walls of parts, inability to overcome vibration, low production efficiency and yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

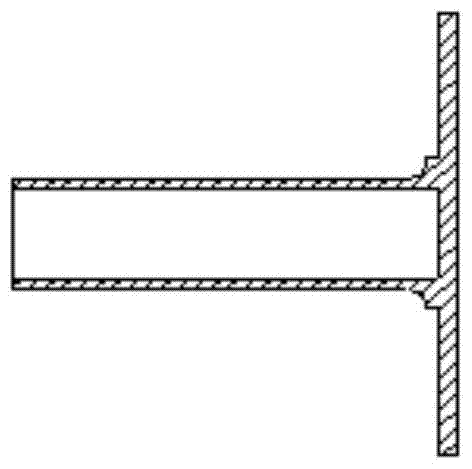

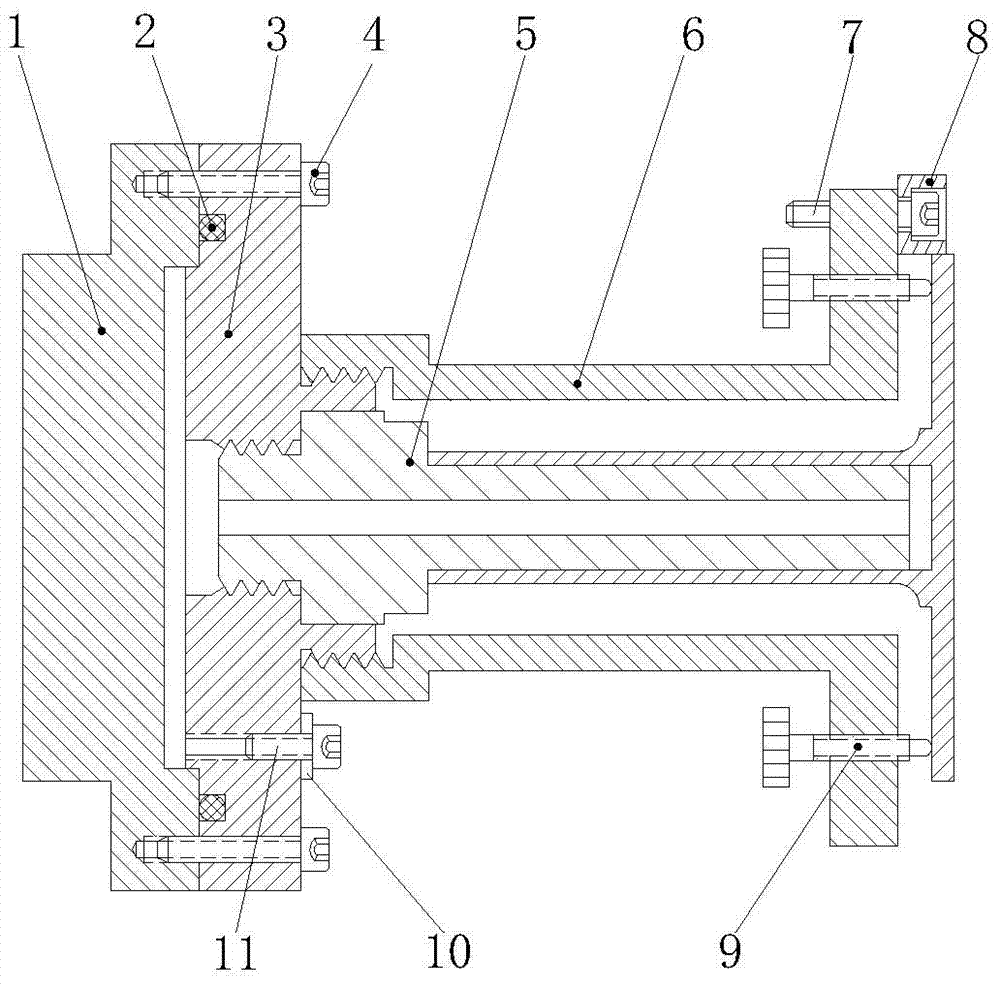

[0032] A sealed and adsorbed adjustable support device for processing thin planes, which consists of a base 1, a sealing ring 2, a positioning mounting plate 3, a connecting screw 4, a positioning mandrel 5, an adjustable support screw seat 6, a fixing screw 7, a stopper Rotary block 8, adjustable support screw 9, sealing gasket 10 and sealing screw 11 are formed.

[0033] The base 1 is a disc with internal and external steps, which is composed of a clamping step 1-1 and a connecting plate 1-2. The clamping step 1-1 is used for lathe clamping, and its outer diameter is 120 -130mm, length 15-20mm; connecting plate 1-2 connected to it has an outer diameter of 165-175mm, length 15-20mm, and its end face 1-4 has four or six equally divided and penetrating internal thread holes 1 -3, its indexing diameter is Φ140-150mm, the internal thread hole specification is M4-M6, the inner step hole 1-5 on the same side as the end face 1-4 is used for positioning, the inner diameter is Φ110±2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com