Frame tailor-welding tooling and tailor-welding method

A frame and welder technology, applied in the field of frame tailor welding tooling and tailor welding, can solve the problems of not being perpendicular to the bottom frame, affecting the operation of the whole machine, prone to skew, etc., to ensure the verticality of the longitudinal axis, and the positioning operation is simple. The effect of fast and easy deviation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0036] The dry-type coal separator frame is 9 meters long, 2.5 meters wide, and weighs more than 4 tons. The drive drum, reversing drum, lower idler, buffer idler assembly, receiver box and other components need to be installed on the rack. Finally, the parallelism between them must be ensured, and the longitudinal axis of the rack must be vertical, otherwise it will affect the operation of the whole machine.

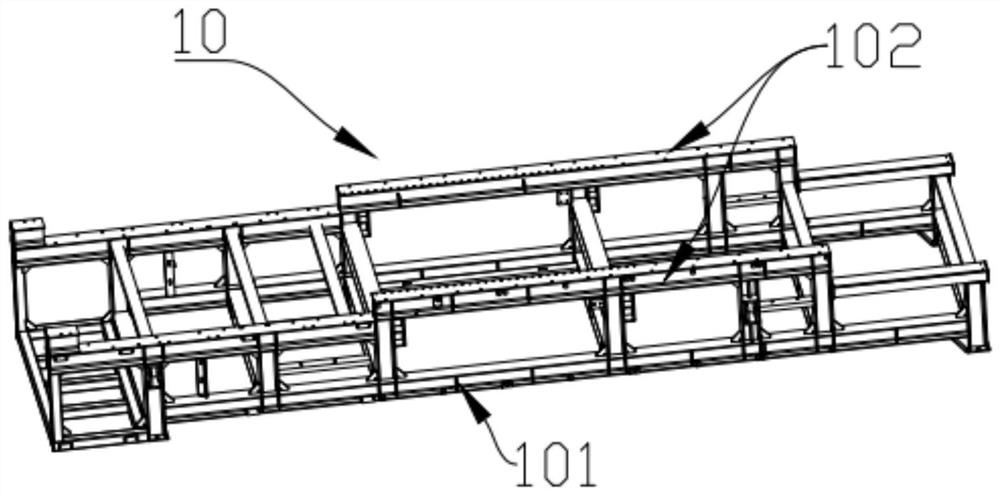

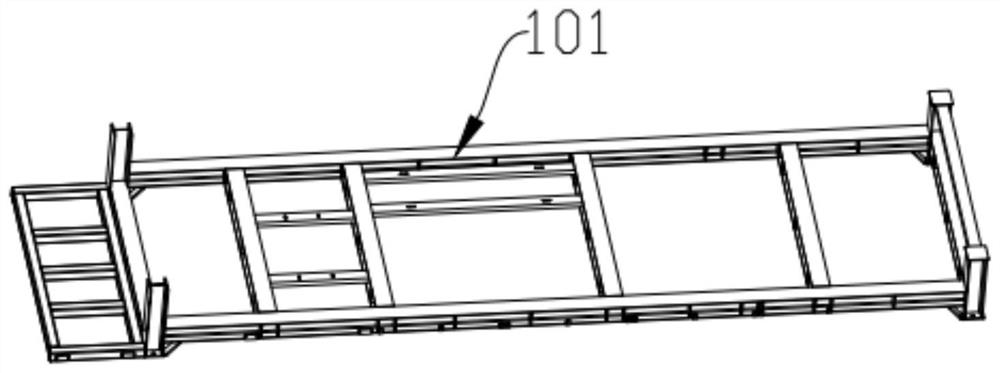

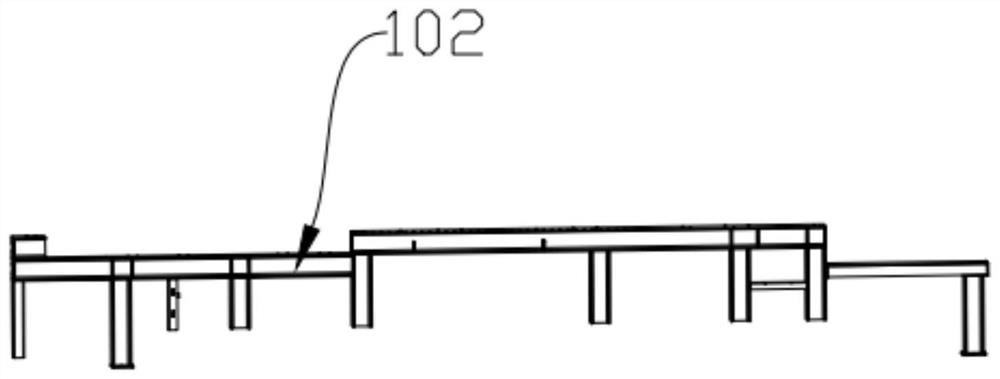

[0037] Such as Figure 1 to Figure 3 As shown, in the prior art, the welding process of the frame assembly 10 is: tailor-weld the bottom frame assembly 101, and then respectively tailor-weld each part of the side frame assembly 102 on the bottom frame assembly 101, after the welding is completed, There is a large error in the parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com