Automatic clamping intelligent welding equipment for centering clamping jaw for building aluminum template production line

An aluminum formwork and production line technology, which is applied in the field of automatic clamping intelligent welding equipment, can solve the problems of low welding efficiency, inconsistent shape, size and position of solder joints, large verticality errors between clamping plate 11 and fixed plate 12, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

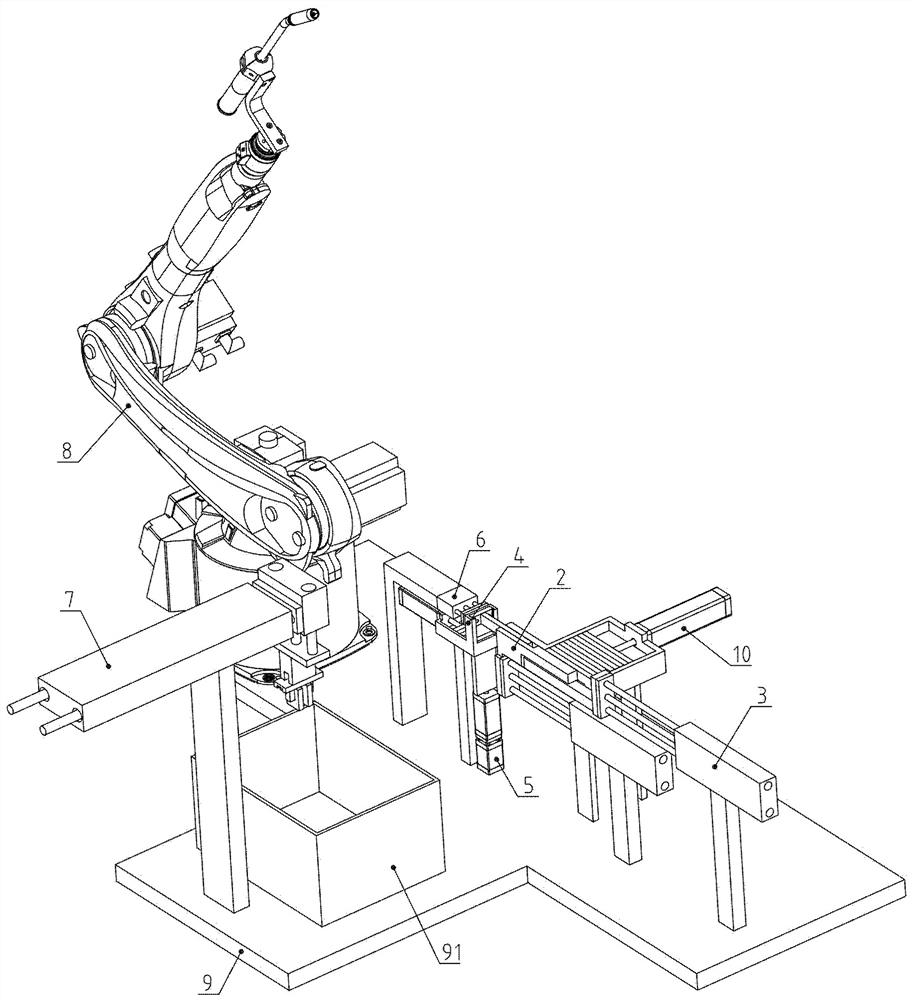

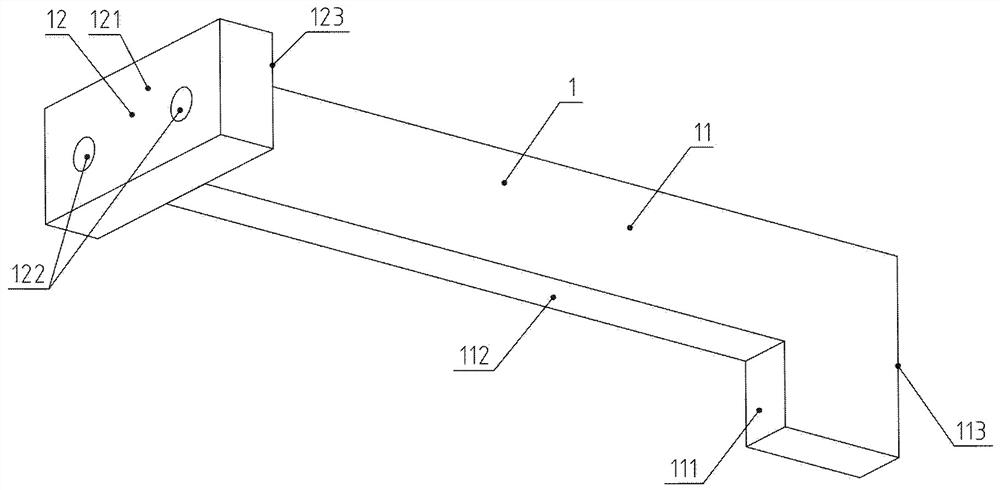

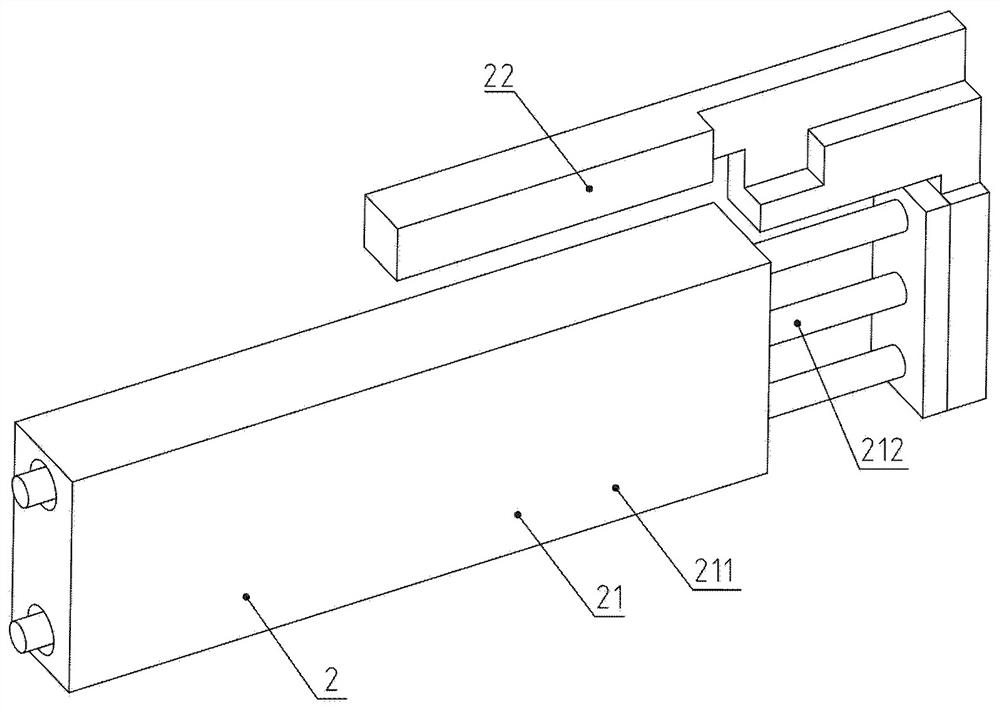

[0064] Example: see Figure 1 to Figure 12 .

[0065] An automatic clamping intelligent welding equipment for centering clamping jaws for construction aluminum template production line, including finished product handling assembly 7, welding robot 8, and frame 9;

[0066] The finished product handling assembly 7 includes a finished product translational handling cylinder 71, a finished product lifting handling cylinder 72, a finished product pneumatic finger 73 and two finished product clamping plates 74; the finished product translation handling cylinder 71 and the finished product lifting handling cylinder 72 are cylinders with guide rods; The handling cylinder 71 includes a finished product translational handling cylinder block 711 and a finished product translational handling cylinder piston rod 712; the finished product lifting handling cylinder 72 includes a finished product lifting handling cylinder block 721 and a finished product lifting handling cylinder piston rod 722; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com