Electromagnetic shielding composite membrane material and preparation and application thereof

A technology of electromagnetic shielding and composite film, which is applied in the fields of magnetic field/electric field shielding, application, and other household appliances, etc. It can solve the problems of poor bonding ability between metal and material, easily scratched coating, loss of shielding performance, etc., and achieve electromagnetic shielding performance Excellent, not easy to wear, improve safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The selected size is 20×20cm 2 The carbon nanotube membrane 1 (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), the thickness of the membrane is 20 μm, the porosity is 75%, the tensile strength is about 200MPa, and the electrical conductivity is about 1×10 5 S / m;

[0036] (2) select the graphene suspension of 2mg / ml (New Material Co., Ltd.);

[0037] (3) Polyaniline (Alfa Aisha Co.), the conductivity of which is 1 S / cm.

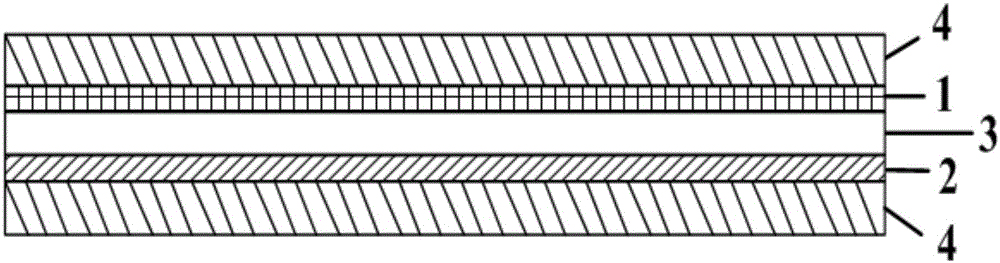

[0038] (4) Mix PDMS (polydimethylsiloxane) liquid (Dow Corning DC184) and curing agent uniformly at a ratio of 10:1 to obtain PDMS liquid adhesive 3, and the protective layer resin adopts water-soluble polyurethane resin 4 (Bayer Technology Ltd.).

[0039] Preparation steps:

[0040] The uniformly dispersed graphene suspension was deposited on a layer of ultra-thin carbon nanotube film through Buchner funnel suction filtration, and dried naturally at room temperature to obtain an ultra-thin carbon nanotube / graph...

Embodiment 2

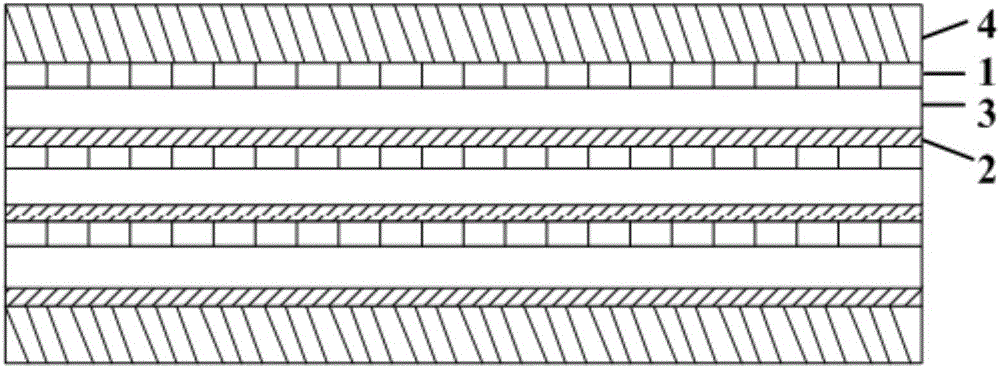

[0045] (1) The selected size is 60×20cm 2 The carbon nanotube membrane 1 (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), the thickness of the membrane is 20 μm, the porosity is 75%, the tensile strength is about 200MPa, and the electrical conductivity is about 1×10 5 S / m;

[0046] (2) select the graphene suspension of 2mg / ml (New Material Co., Ltd.);

[0047] (3) Polyaniline (Alfa Aisha Co.), the conductivity of which is 1 S / cm.

[0048] (4) Mix PDMS (polydimethylsiloxane) liquid (Dow Corning DC184) and curing agent in a ratio of 10:1 to obtain PDMS liquid adhesive 3, and coat the upper and lower surfaces of the carbon nanotube composite film As protective layer resin 4.

[0049] Preparation steps:

[0050] The uniformly dispersed graphene suspension was deposited on a layer of ultra-thin carbon nanotube film through Buchner funnel suction filtration, and dried naturally at room temperature to obtain an ultra-thin carbon nanotube / graphene...

Embodiment 3

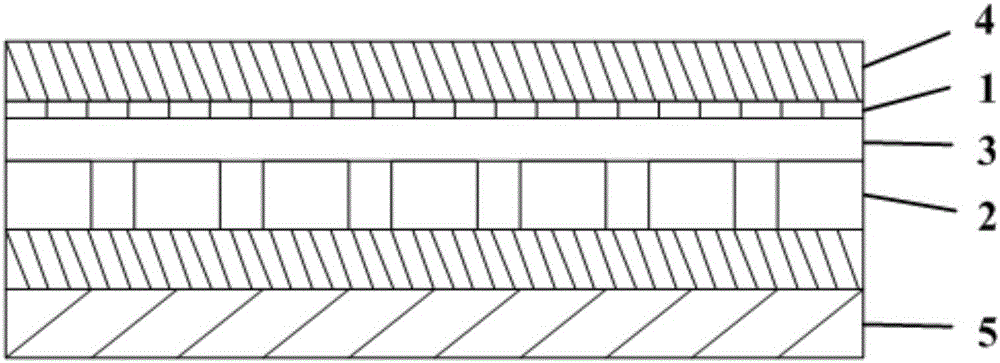

[0054] (1) The selected size is 20×20cm 2 The carbon nanotube membrane 1 (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), the thickness of the membrane is 20 μm, the porosity is 75%, the tensile strength is about 200MPa, and the electrical conductivity is about 1×10 5 S / m;

[0055] (2) select the graphene suspension of 2mg / ml (New Material Co., Ltd.);

[0056] (3) Polyaniline 2 (Alfa Aisha Co.), the conductivity of which is 1 S / cm.

[0057] (4) Mix PDMS (polydimethylsiloxane) liquid (Dow Corning DC184) and curing agent uniformly at a ratio of 10:1 to obtain PDMS liquid adhesive 3, and the protective layer resin adopts water-soluble polyurethane resin 4 (Bayer Technology Ltd.).

[0058] (5) Use acrylic transparent double-sided adhesive tape 5 (Shanghai Canxing Composite Material Co., Ltd.) with a thickness of 0.5mm, and the size is 20×20cm 2 .

[0059] Preparation steps:

[0060] The uniformly dispersed graphene suspension was deposited o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com