Container and packaging body

A packaging and container technology, applied in packaging, wrapping paper, household packaging, etc., can solve problems such as finger pain, cost increase, and discomfort, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

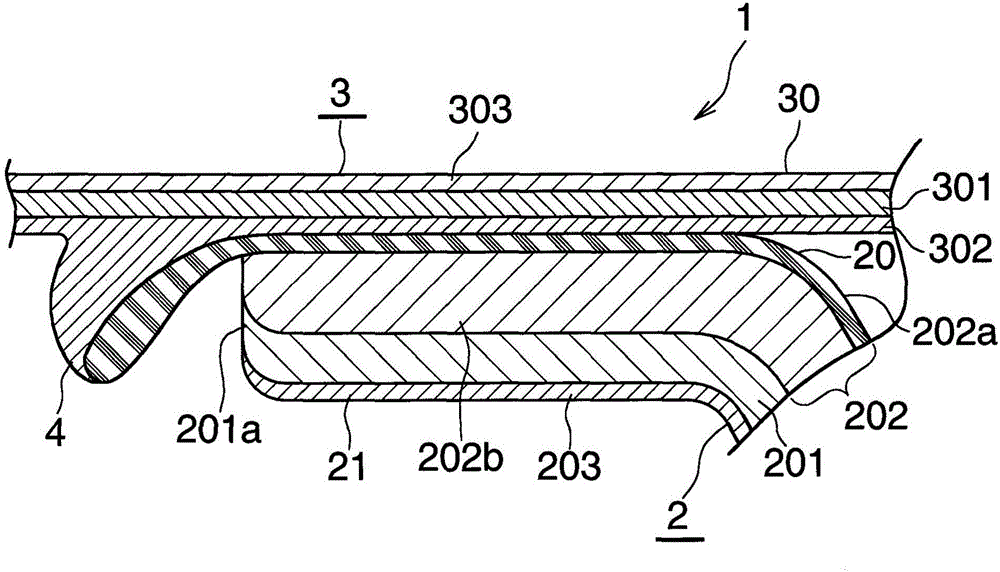

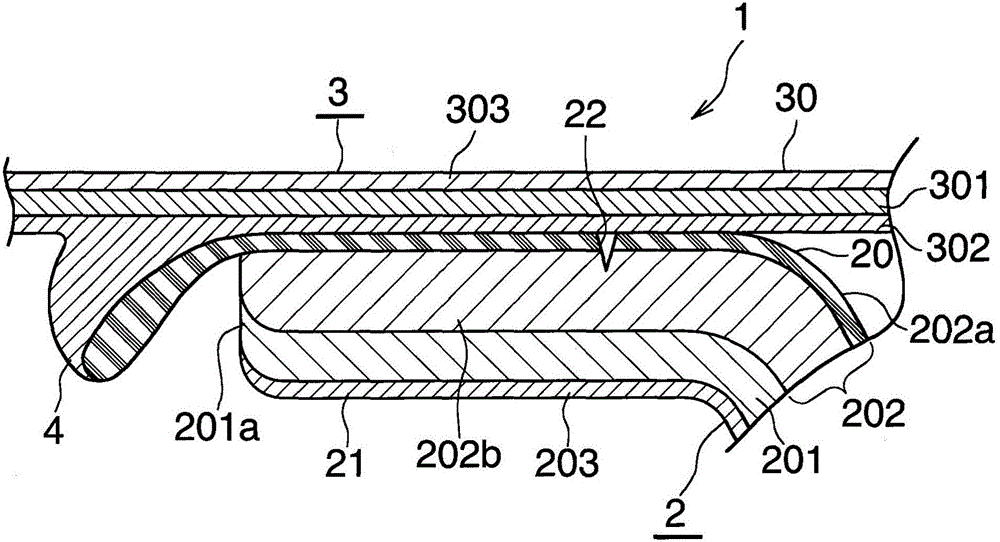

[0044] Below, refer to Figure 1~4 Embodiments of this invention will be described.

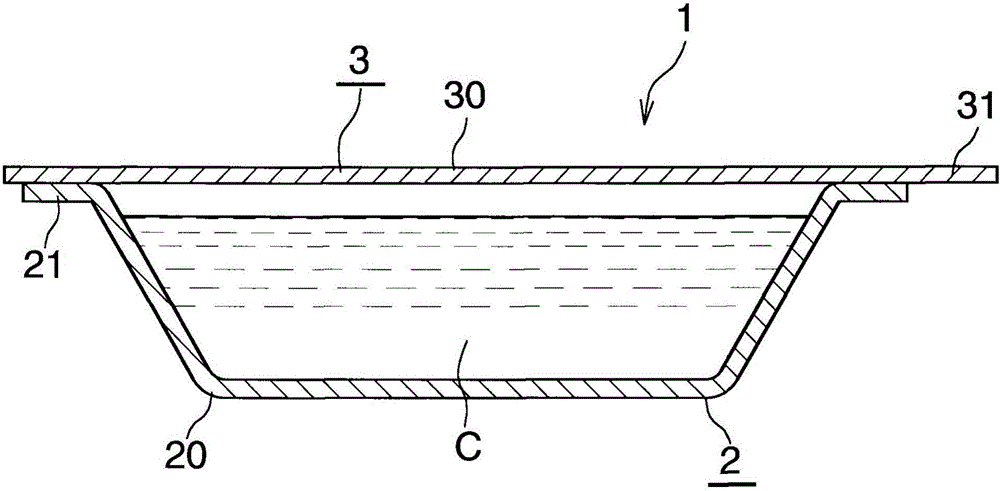

[0045] figure 1 The overall configuration of the package of the present invention is shown.

[0046] The illustrated package 1 is configured by filling and packaging contents C such as food with a container 2 and a cover 3 .

[0047] The container 2 is formed by molding a composite sheet 20 into a cup shape, and has a horizontal flat flange portion 21 on its upper opening periphery.

[0048] The lid 3 is composed of a composite sheet 30 cut into a predetermined size and shape, and its peripheral edge is thermally welded to the upper surface of the flange portion 21 of the container 2 so as to cover the upper opening of the container 2 filled with the contents C. .

[0049] In addition, a handle portion 31 is formed on the cover 3, and the handle portion 31 protrudes radially outward from a part of the peripheral portion of the cover 3 and is gripped with fingers when the cover 3 is peeled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com