Particle or powder material sample collection bucket

A technology for sample collection and powdery materials, which is applied in the direction of locking equipment, closing, packaging, etc., can solve the problems of sample moisture loss, daily consumables, large dust, etc., to prevent moisture loss, realize confidential management, and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] As mentioned in the background technology section, the current sample collection containers cannot simultaneously achieve the purposes of confidential management and reuse of samples.

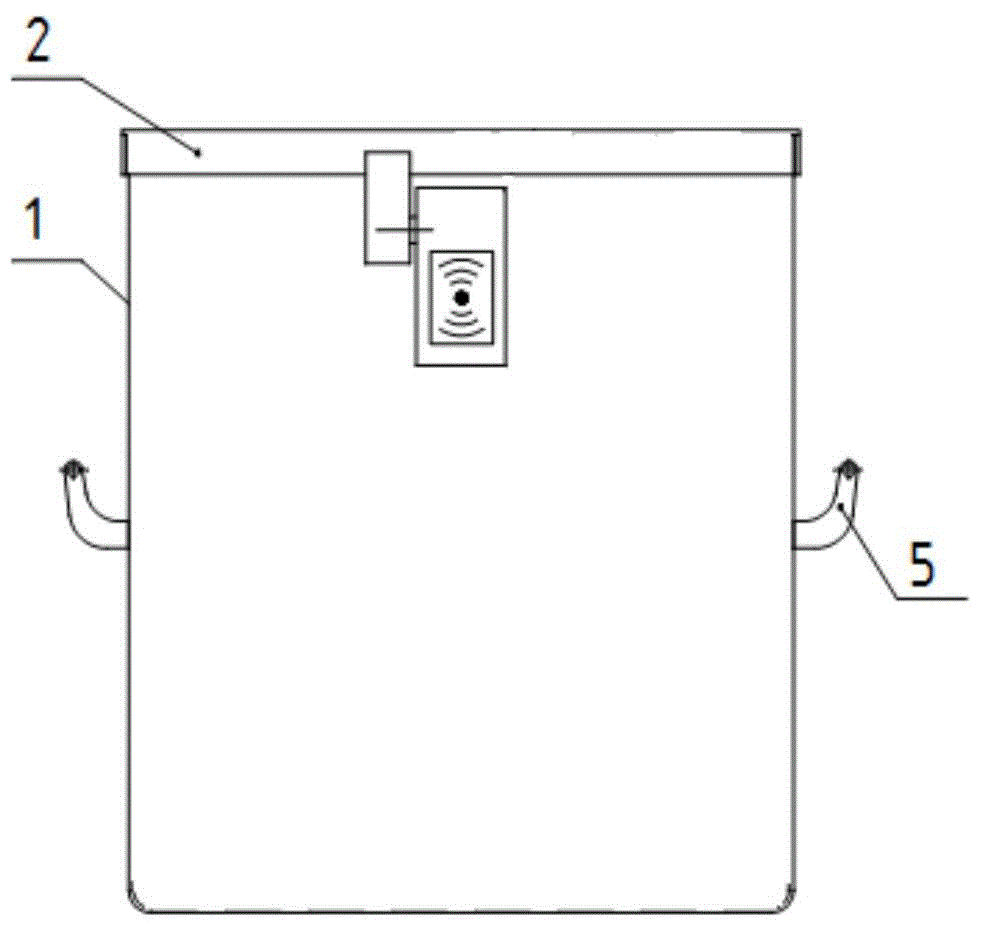

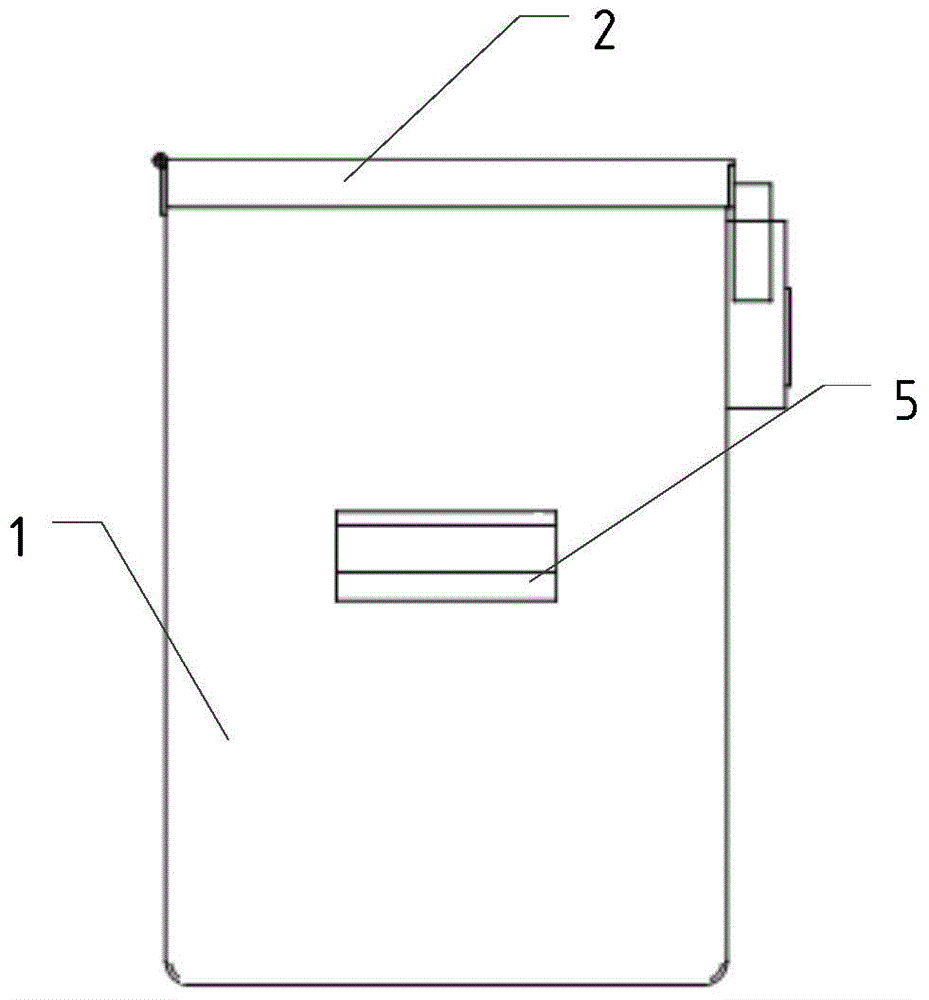

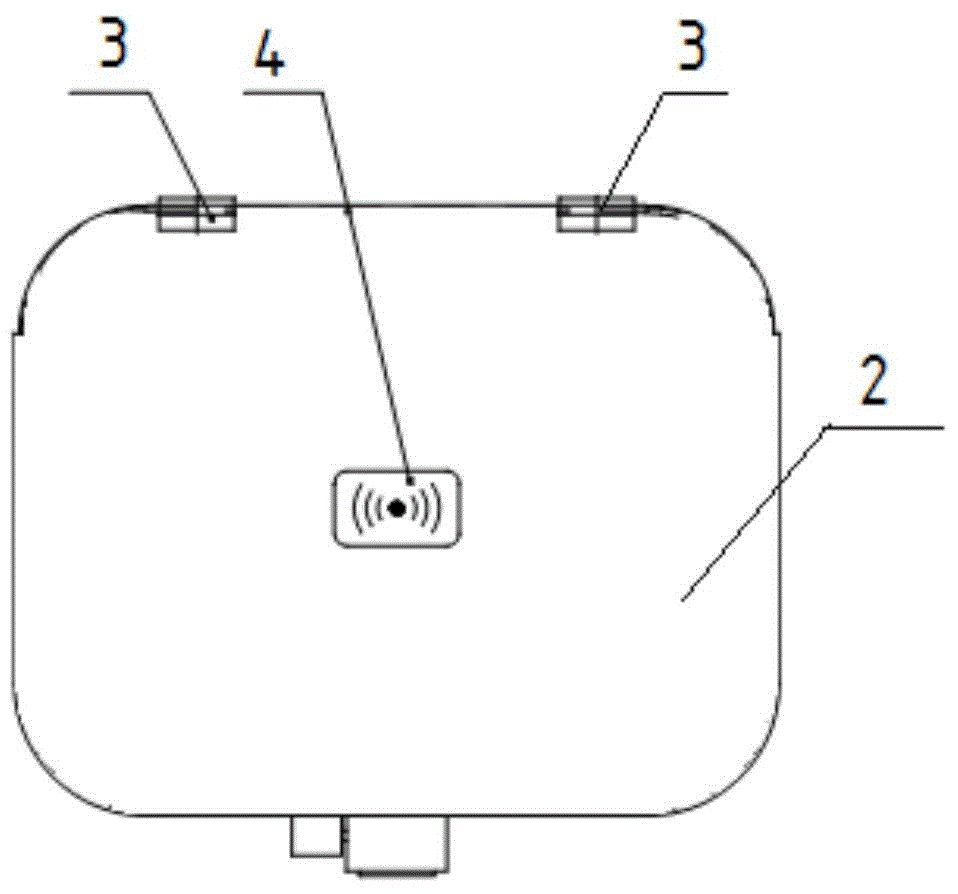

[0020] Based on the above research, an embodiment of the present invention provides a bucket for collecting samples of granular or powdery materials, including: a bucket body and a bucket cover, wherein the bucket body and the bucket cover are hinged by a hinge, and the bucket body and the bucket cover are hinged. An electronic lock, combination lock or fingerprint lock is arranged between the lids.

[0021] The sample collection barrel for granular or powdery materials provided by the embodiment of the present invention ensures a one-to-one correspondence between the barrel body and the barrel lid, avoids sample contamination caused by the cross-use of barrel lids of different sample collection barrels, and selects the lock type according to actual needs , to realize the confidential ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com