A brine refining device and method for directly removing calcium and magnesium

A brine refining, calcium and magnesium technology, applied in electrodialysis, alkali metal halide purification and other directions, can solve the problems of low efficiency, high cost, complicated process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

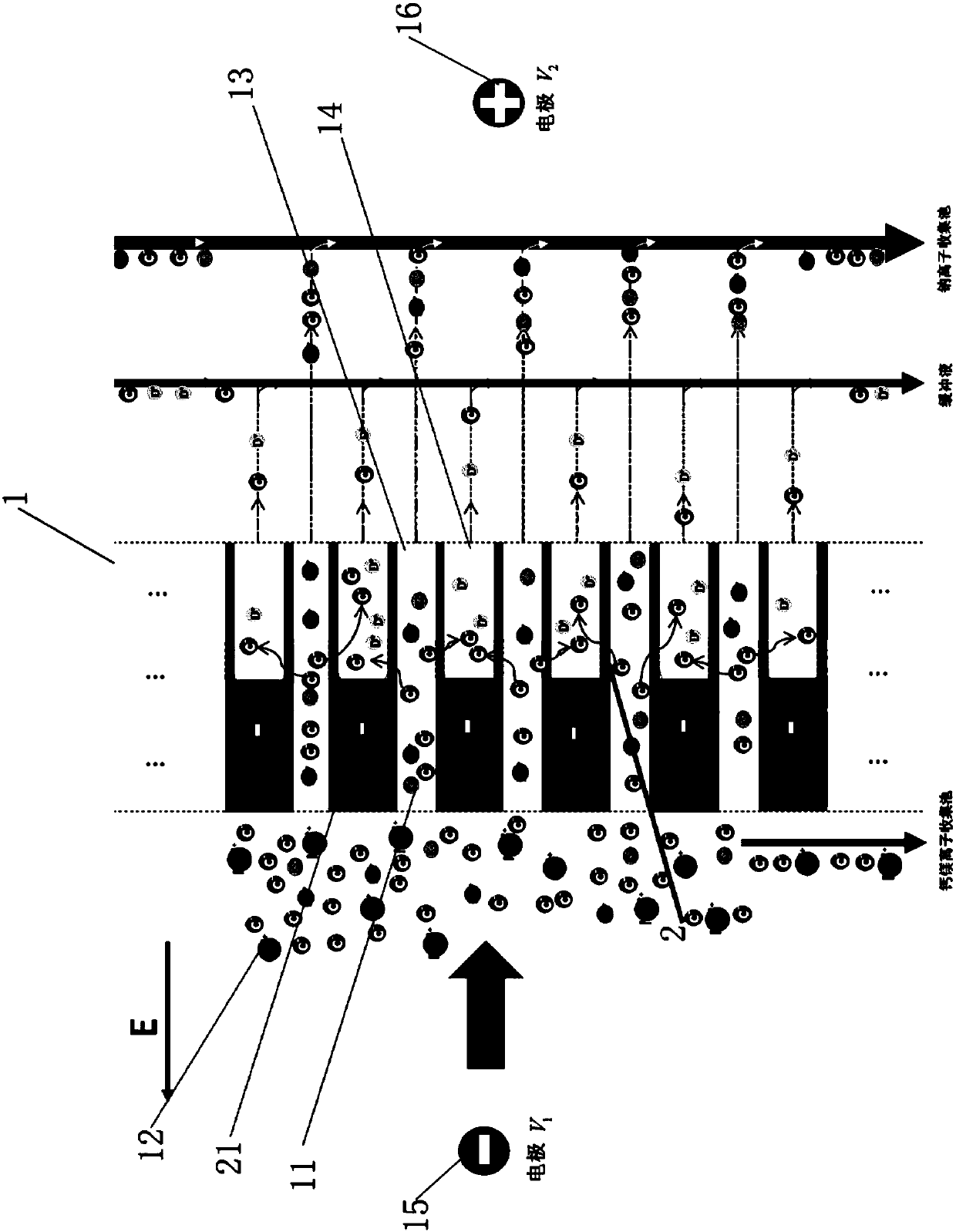

[0016] Such as figure 1 Shown, the brine refining method that the present invention proposes, to magnesium ion (Mg 2+ ), calcium ions (Ca 2+ ) and sodium ions (Na + ) for separation, the method mainly lies in the design of the separation membrane. Here, an enlarged view of the separation membrane is shown. As shown in the figure, the surface of the separation membrane 1 is micro-machined, and countless micro-channels 11 are etched (the channel size can be controlled between 10um and 100um, because the channel pressure is proportional to the -4th power of the pore diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com