Foam scraping type sewage treating equipment

A sewage treatment equipment and foam-scraping technology, which is used in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. The problems such as the impurity cannot float up, and the effect of enhancing the evolution effect is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

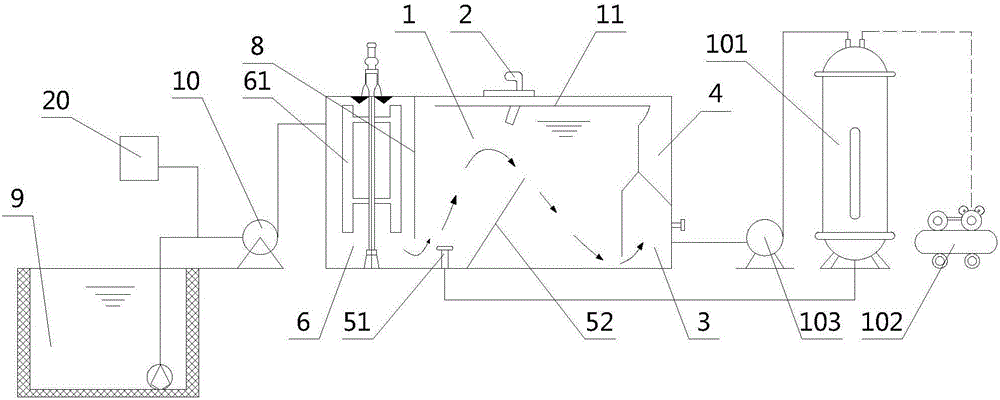

[0021] Such as figure 1 As shown, a scraping type sewage treatment equipment provided in this embodiment includes an air flotation tank 1, a scraping machine 2, a storage tank 3, a sludge tank 4, a stirring tank 6 and a regulating tank 9, and the wastewater medium flows through in sequence The regulating pool 9, the stirring pool 6, the air flotation pool 1 and the storage pool 3 are finally discharged from the storage pool 3, that is, the regulating pool 9 is located upstream of the stirring pool, the stirring pool 6 is located upstream of the air flotation pool 1, and the air flotation pool 1 is located in the storage pool 3 Upstream, the regulating tank 9 is provided with an inlet and a screen for the sewage medium. When the sewage medium enters the regulating tank 9, it will be clarified and scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com