Method for preparing concrete water reducing agent with p-styrene sulfonate as monomer

A technology of styrene sulfonate and concrete water reducing agent, which is applied in the field of preparing concrete water reducing agent, can solve the problems of restricting application improvement effect and the like, and achieves the effect of improving application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

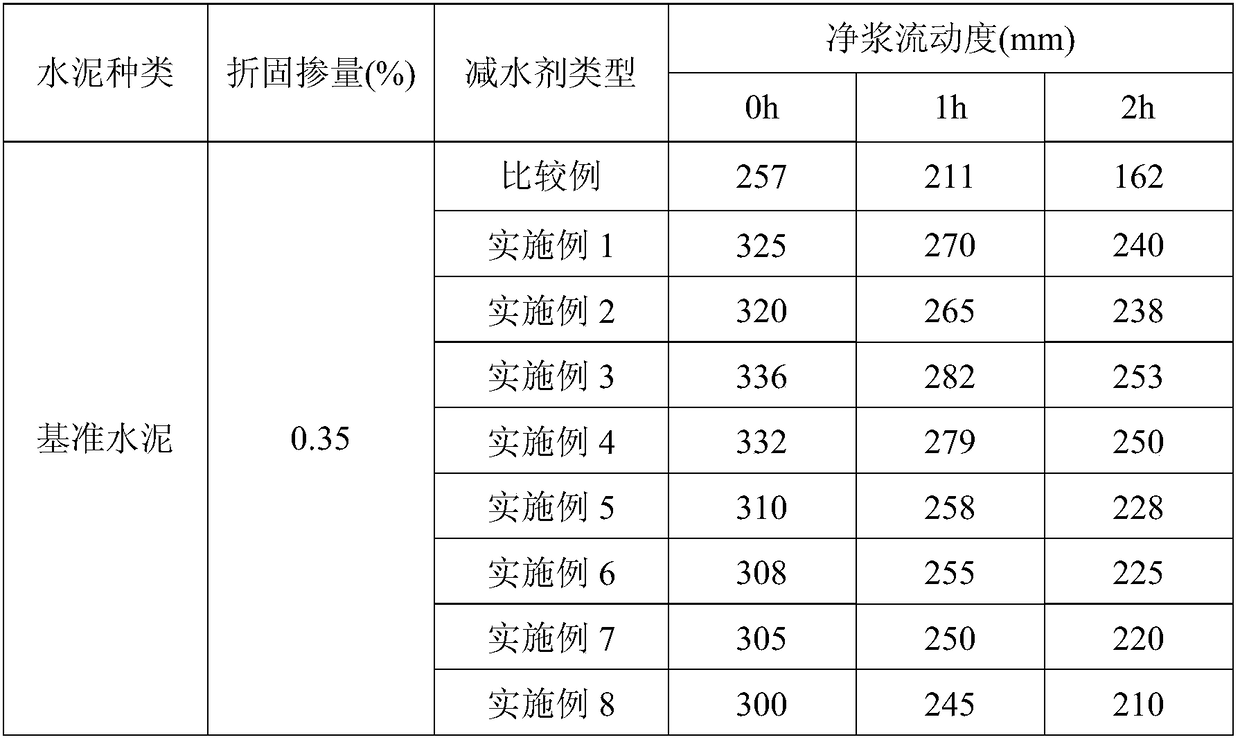

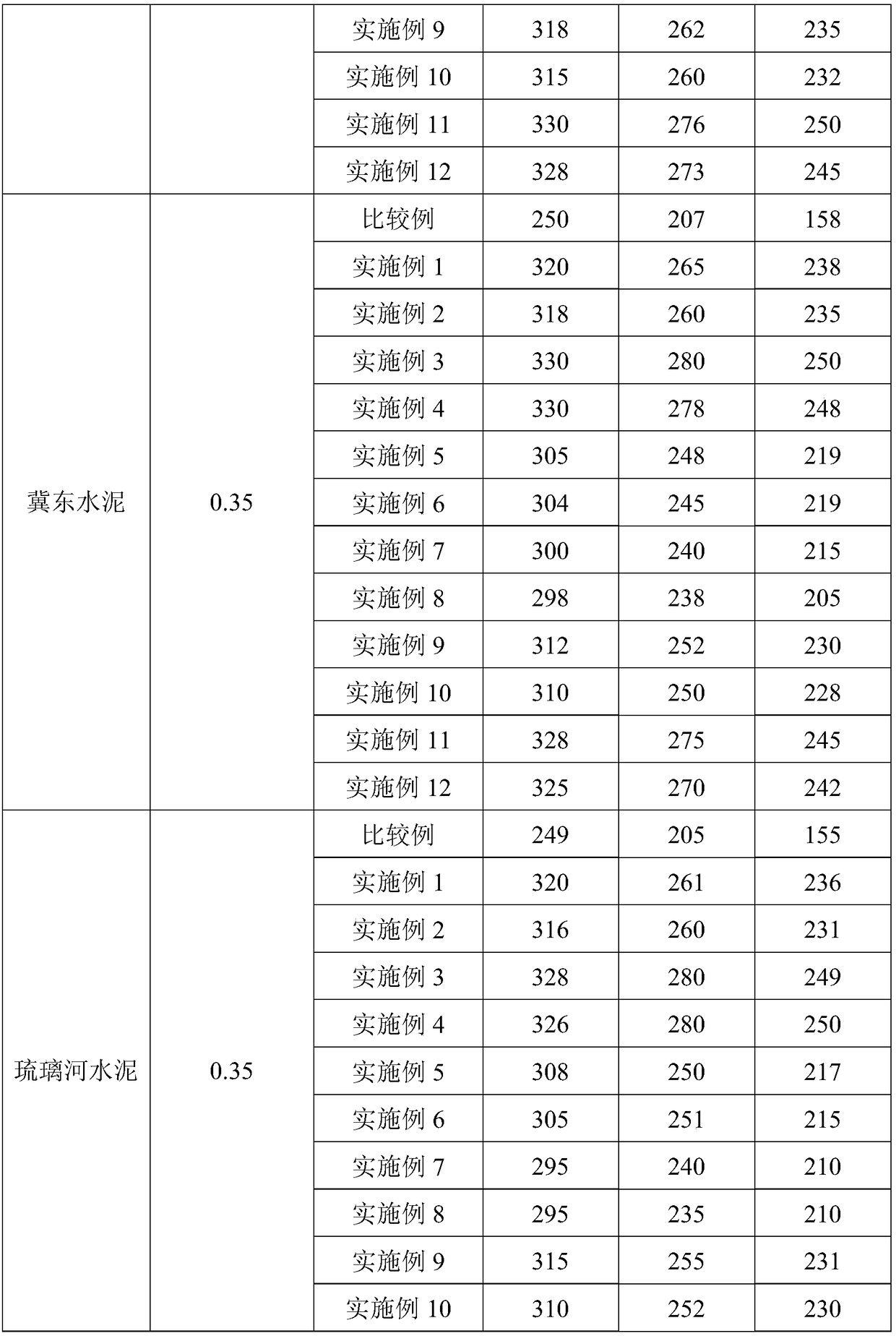

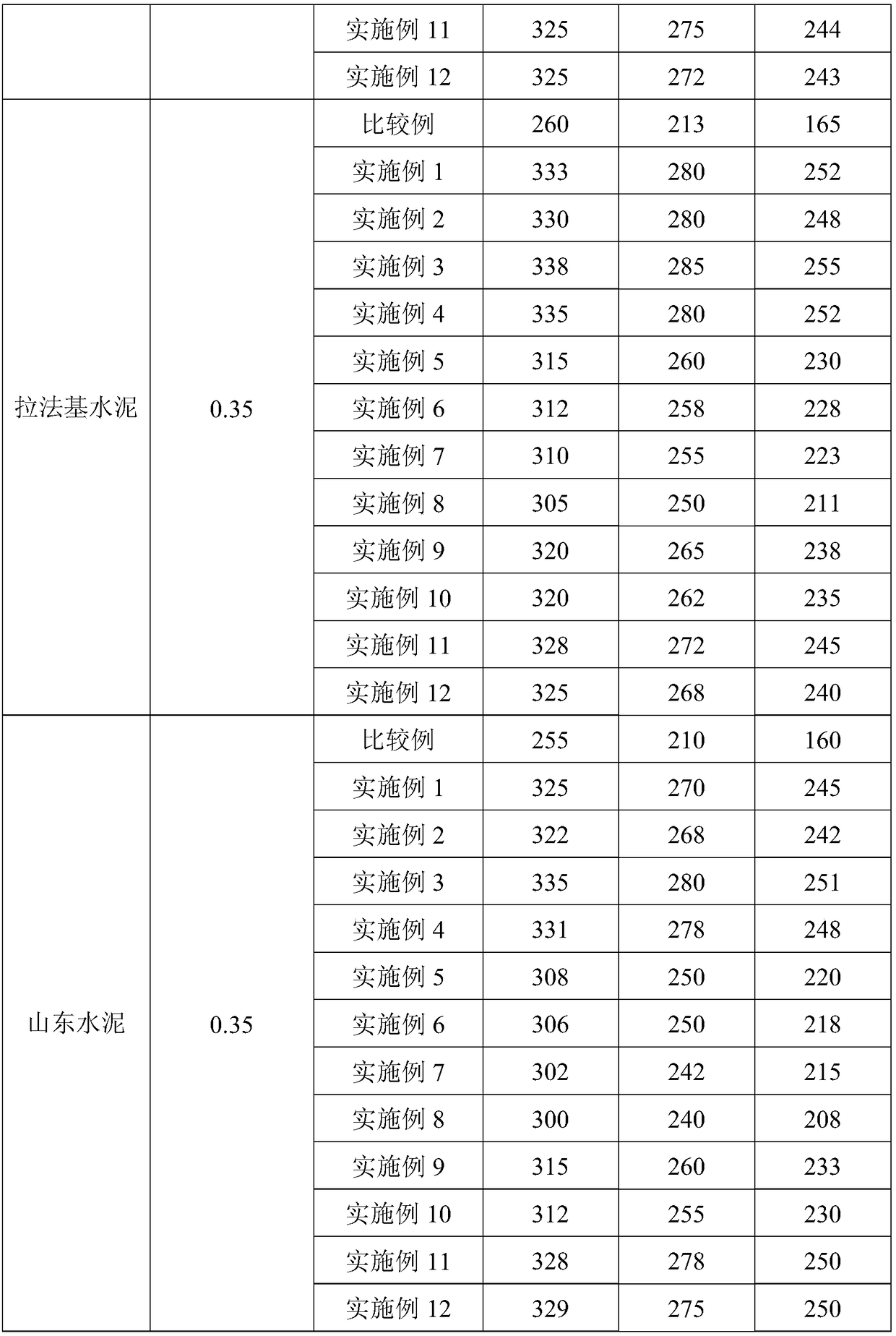

Examples

Embodiment 1

[0029] First, add 1.43g methacrylic acid, 10.84g itaconic acid, 6.19g sodium p-styrene sulfonate, 14.77g water, 1.23g sodium methacrylate sulfonate, 21.67g mass fraction of 10% peroxide in the reactor Sodium sulfate aqueous solution, and the stirring time between each feeding is 5 minutes, and the temperature is raised to 60 ° C to carry out polymerization reaction, and the reaction is 6.5 hours to obtain the polycarboxylic acid-styrene sulfonate aqueous solution; the obtained polycarboxylic acid-styrene sulfonic acid Vacuumize the brine solution to remove moisture in the system, add 64.61g of dimethylformamide, stir for 12 minutes, add 6.24g of thionyl bromide dropwise to the reactor within 0.7 hours under ice-water bath conditions, and control the temperature at 3°C for constant temperature reaction After 17 hours, 123.49g of methanol was added to wash the precipitate repeatedly 3 times, and the precipitate was vacuum-dried at 80°C to constant weight to obtain polycarboxyli...

Embodiment 2

[0031] After storing the 30% concrete water reducer solution obtained in Example 1 at 6° C. for 30 days, its implementation effect was measured.

Embodiment 3

[0033] First, add 2.87g methacrylic acid, 4.34g itaconic acid, 3.87g maleic acid, 5.15g sodium p-styrene sulfonate, 16.23g water, 0.57g thioglycolic acid, 7.13g mass fraction to the reactor at 20% Ammonium persulfate aqueous solution, and the stirring time between each feeding is 11 minutes, and the temperature is raised to 75°C for polymerization reaction, and the reaction is 4.5 hours to obtain the polycarboxylic acid-styrene sulfonate aqueous solution; the obtained polycarboxylic acid-styrene Sulfonate aqueous solution was vacuumed to remove moisture in the system, 40.57g dimethyl sulfoxide was added, stirred for 14 minutes, 3.57g thionyl chloride was added dropwise to the reactor within 0.6 hours in an ice-water bath, and the temperature was controlled at 4°C to maintain a constant temperature After reacting for 16 hours, add 158.39g of methanol to wash the precipitate repeatedly 5 times, and vacuum-dry the precipitate to constant weight at 65°C to obtain polycarboxylic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com