Rapid photodegradable plastic film

A plastic film and photodegradation technology, applied in the field of degradable plastic film, can solve the problems of white pollution, long degradation time of plastic film, cotton production reduction, etc., and achieve the effect of good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

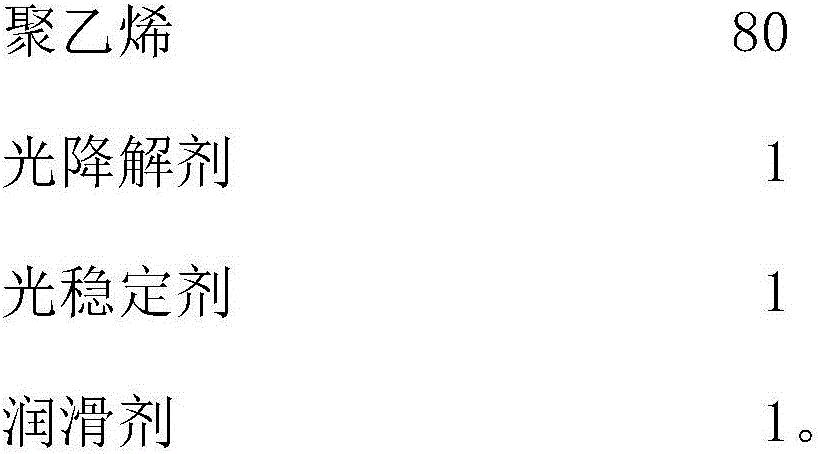

[0016] Express photodegradable plastic film, the film is blown from masterbatch, and the masterbatch includes the following substances and parts by weight:

[0017]

[0018] The photodegradant is iron dialkyldithiocarbamate.

[0019] The light stabilizer is 2-methoxy-5-[2-(3,4,5-trimethoxyphenyl) ethyl]phenol, diphenyl phosphoric azide, 2-(2-nitro A mixture of anilino)-3-cyano-5-methylthiophene, 2-methoxy-5-[2-(3,4,5-trimethoxyphenyl)ethyl]phenol, diphosphoryl azide The weight ratio of phenyl ester to 2-(2-nitroanilino)-3-cyano-5-methylthiophene is 1:0.01:0.1.

[0020] Described lubricant is zinc stearate;

[0021] The polyethylene includes 60% high-density polyethylene and 40% linear low-density polyethylene in weight percent concentration;

Embodiment 2

[0023] Express photodegradable plastic film, the film is blown from masterbatch, and the masterbatch includes the following substances and parts by weight:

[0024]

[0025] The photodegradant is iron dialkyldithiocarbamate.

[0026] The light stabilizer is 2-methoxy-5-[2-(3,4,5-trimethoxyphenyl) ethyl]phenol, diphenyl phosphoric azide, 2-(2-nitro A mixture of anilino)-3-cyano-5-methylthiophene, 2-methoxy-5-[2-(3,4,5-trimethoxyphenyl)ethyl]phenol, diphosphoryl azide The weight ratio of phenyl ester to 2-(2-nitroanilino)-3-cyano-5-methylthiophene is 1:0.3:0.3.

[0027] Described lubricant is zinc stearate;

[0028] The polyethylene includes 70% high-density polyethylene and 30% linear low-density polyethylene by weight;

Embodiment 3

[0030] Express photodegradable plastic film, the film is blown from masterbatch, and the masterbatch includes the following substances and parts by weight:

[0031]

[0032] The photodegradant is iron dialkyldithiocarbamate.

[0033] The light stabilizer is 2-methoxy-5-[2-(3,4,5-trimethoxyphenyl) ethyl]phenol, diphenyl phosphoric azide, 2-(2-nitro A mixture of anilino)-3-cyano-5-methylthiophene, 2-methoxy-5-[2-(3,4,5-trimethoxyphenyl)ethyl]phenol, diphosphoryl azide The weight ratio of phenyl ester to 2-(2-nitroanilino)-3-cyano-5-methylthiophene is 1:0.05:0.5.

[0034] Described lubricant is zinc stearate;

[0035] The polyethylene includes 75% high-density polyethylene and 25% linear low-density polyethylene by weight;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com