Thermoplastic polyvinyl alcohol material and preparation method thereof

A polyvinyl alcohol and thermoplastic technology, which is applied in the field of thermoplastic polyvinyl alcohol materials and its preparation, can solve the problems of complex precursor preparation process, unsatisfactory production efficiency, and low tensile strength of products, and achieve better gloss and improved Process fluidity, effect of process fluidity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

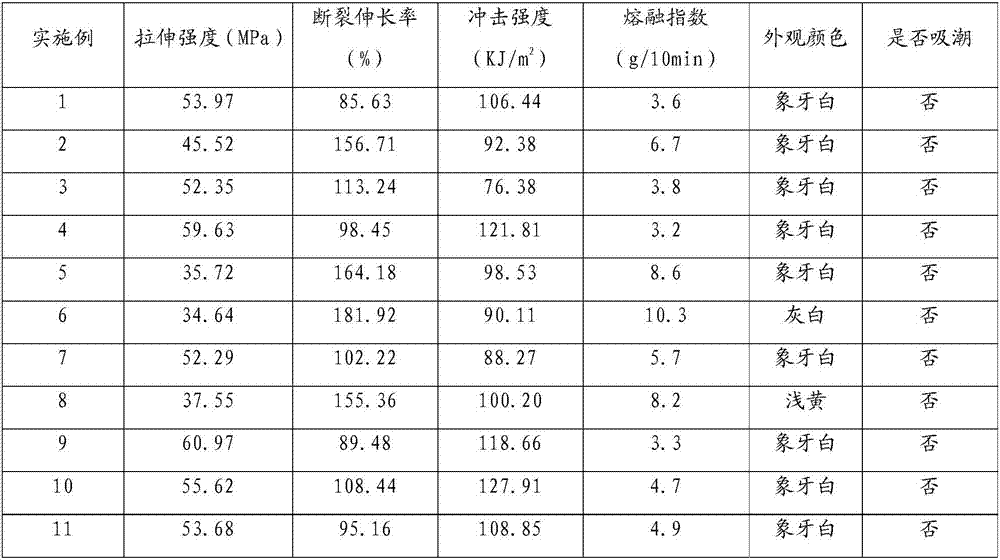

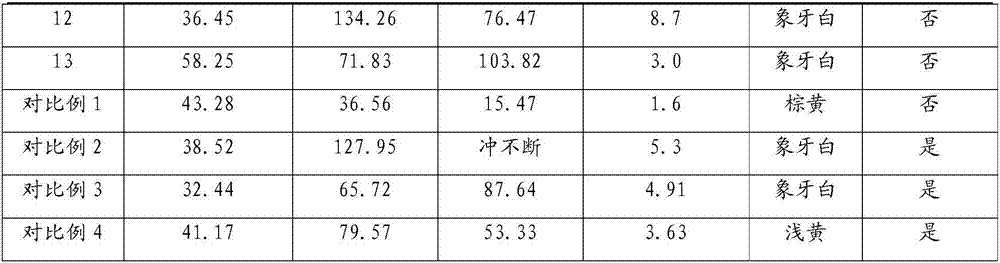

Examples

Embodiment 1

[0028] Be 100 parts of polyvinyl alcohols with a degree of polymerization of 1700 and a degree of alcoholysis of 99%, 5 parts of polylactic acid (poly-L-lactic acid) with a weight average molecular weight of 120,000, pentaerythritol-mannitol composite plasticizer (pentaerythritol and nectar) The mass ratio of alcohol is 8:7) 20 parts, 1 part of stearic acid, 1 part of anti-oxidant 1010 and 2 parts of calcium stearate are mixed uniformly in high mixer, obtains precursor; Then precursor is extruded with twin-screw Extrude and granulate under the conditions of 170°C in the first zone, 180°C in the second zone, 200°C in the third zone, 200°C in the fourth zone, 200°C in the fifth zone, 200°C in the sixth zone, 200°C in the head, and 150rpm of the screw speed to obtain Thermoplastic polyvinyl alcohol material.

Embodiment 2

[0030] Be that 1000, degree of alcoholysis be 100 parts of polyvinyl alcohols of 99% by degree of polymerization, 8 parts of polylactic acid with weight-average molecular weight of 80,000, pentaerythritol-mannitol composite plasticizer (the mass ratio of pentaerythritol and mannitol is 7: 6) 25 parts, 2 parts of stearic acid, 1 part of anti-oxidant 1010 and 2 parts of zinc stearate were mixed uniformly in a high-speed mixer to obtain a precursor; , 175°C in the second zone, 185°C in the third zone, 190°C in the fourth zone, 195°C in the fifth zone, 195°C in the sixth zone, extruding and granulating under the conditions of 190°C and 100rpm screw speed to obtain a thermoplastic polyvinyl alcohol material.

Embodiment 3

[0032] Be that 1700, degree of alcoholysis be 100 parts of polyvinyl alcohols of 88% by degree of polymerization, weight-average molecular weight is 10 parts of polylactic acid of 150,000, pentaerythritol-mannitol composite plasticizer (the mass ratio of pentaerythritol and mannitol is 9: 7) 10 parts, 1 part of stearic acid, 1 part of anti-oxidant 1010, 1 part of calcium stearate and 1 part of zinc stearate are mixed uniformly in a high mixer to obtain a precursor; then the precursor is extruded with a twin-screw Extrude and granulate at 160°C in the first zone, 165°C in the second zone, 175°C in the third zone, 180°C in the fourth zone, 185°C in the fifth zone, 195°C in the sixth zone, 190°C at the head, and 120rpm of the screw speed to obtain Thermoplastic polyvinyl alcohol material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com