Crystalline gadolinium-based magnetic refrigeration material and preparation method thereof

A magnetic refrigeration material, gadolinium-based technology, applied in magnetic materials, heat exchange materials, inorganic material magnetism, etc., can solve the problem of limited rare-earth gadolinium-based magnetic refrigeration materials, and achieve good magnetic refrigeration performance, low cost, and good stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1

[0022] The preparation method of the crystalline gadolinium-based magnetic refrigeration material of this embodiment is as follows:

[0023] Add 600 microliters of 1mol / L Gd(NO 3 ) 3 The aqueous solution and 100 microliters of 1mol / L amino trimethylene phosphonic acid aqueous solution were placed in a 15 mL vial, and then 2 mL of deionized water was added, while stirring, 1 mol / L sulfuric acid was added dropwise to adjust the pH When it reaches 1.5, stir for 10 minutes and seal it, then place it in a constant temperature drying oven at 90°C and heat it for 24 hours, and cool to room temperature to obtain a large amount of colorless crystals. Filter, wash three times with water, and dry at room temperature to obtain crystalline gadolinium-based magnetic refrigeration material It was 0.115g, and the yield was 51.3%.

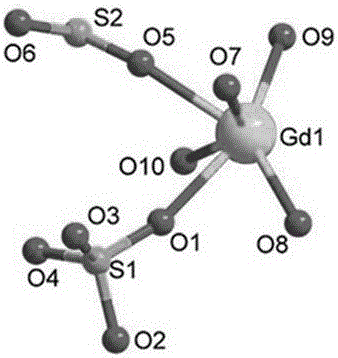

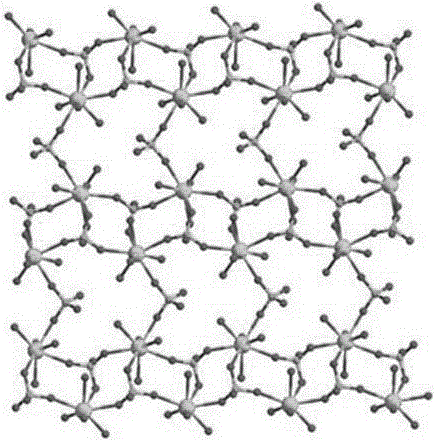

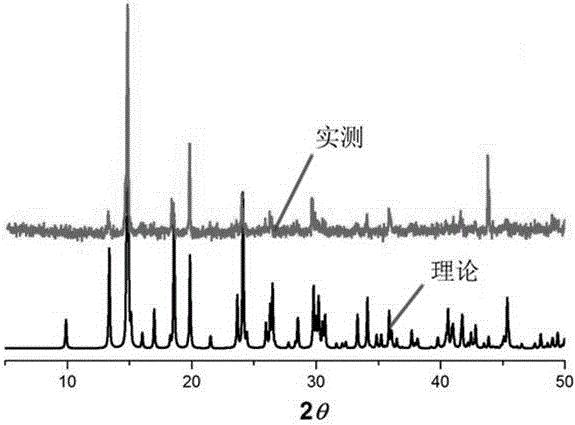

[0024] (1) The obtained crystal samples were characterized by Bruker D8 ADVANCE powder X-ray diffractometer, and the peak positions of the measured an...

Example Embodiment

[0031] Example 2

[0032] The preparation method of the crystalline gadolinium-based magnetic refrigeration material of this embodiment includes the following steps:

[0033] Add 500 microliters of 1mol / L gadolinium nitrate aqueous solution and 100 microliters of 1mol / L aminotrimethylene phosphonic acid aqueous solution into a 15mL reaction flask, then add 6mL deionized water, add 1mol / L dropwise under stirring Sulfuric acid (Sulfuric acid is the construction ligand of the material and is also used to adjust the pH value of the reaction mixture). Adjust the pH of the system to 2, stir for 8 minutes and then seal, heat at a constant temperature of 85°C for 30 hours, cool to room temperature, and filter And drying at room temperature to obtain the gadolinium-based magnetic refrigeration material.

Example Embodiment

[0034] Example 3

[0035] The preparation method of the crystalline gadolinium-based magnetic refrigeration material of this embodiment includes the following steps:

[0036] Add 700 microliters of 1mol / L gadolinium nitrate aqueous solution and 100 microliters of 1mol / L aminotrimethylene phosphonic acid aqueous solution into a 15mL reaction flask, then add 5mL deionized water, and add 1mol / L dropwise under stirring Sulfuric acid (Sulfuric acid is the construction ligand of the material and is also used to adjust the pH value of the reaction mixture). Adjust the pH of the system to 1.5, stir for 10 minutes and then seal, heat at 95°C for 20 hours, cool to room temperature, and filter And drying at room temperature to obtain the gadolinium-based magnetic refrigeration material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com