Technology for extracting gasoline diesel by using waste plastic in domestic garbage landfill site

A waste plastic, gasoline and diesel technology, applied in the petroleum industry, the removal of solid waste, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of secondary pollution of water and soil, poor quality of plastic products, slow natural degradation speed, etc., to achieve Effects of suppressing the spread of soil-borne pathogens, reducing treatment costs, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

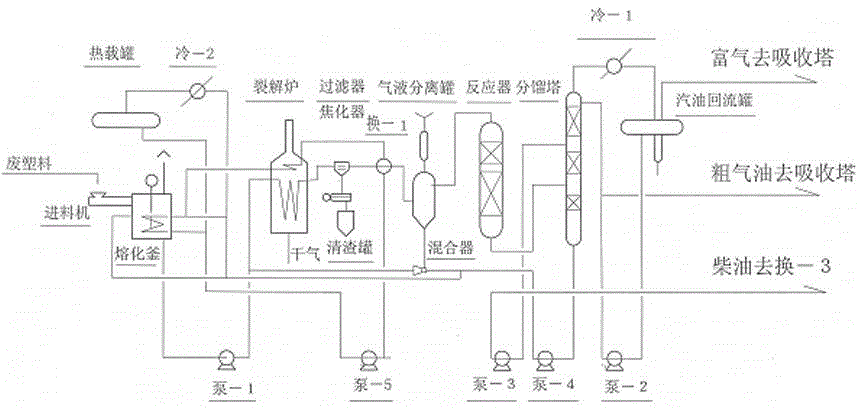

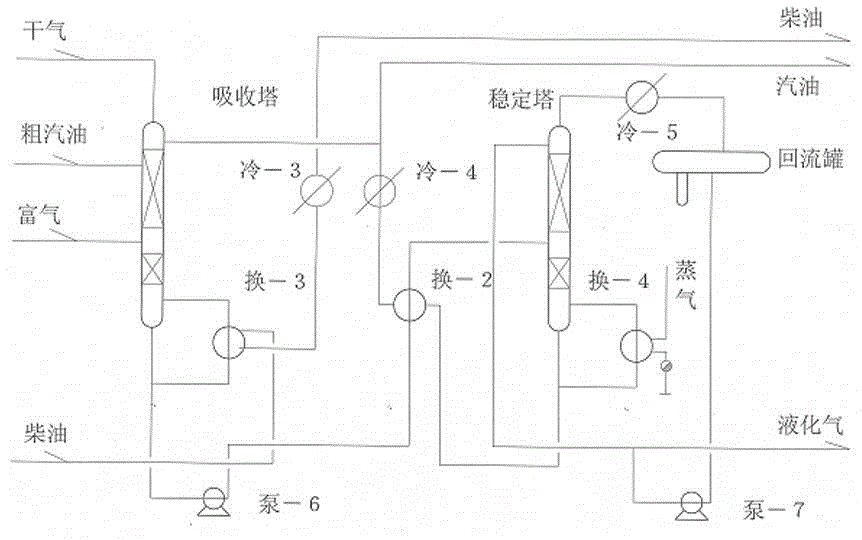

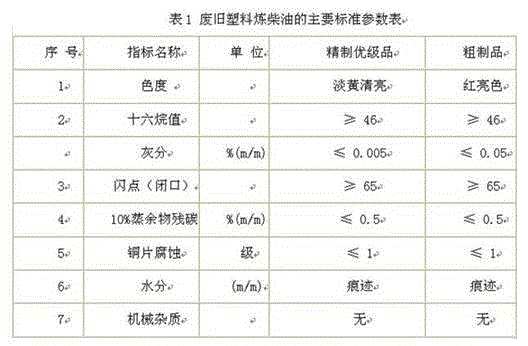

[0039] see Figure 1~2 , in an embodiment of the present invention, a process for extracting gasoline and diesel from waste plastics in domestic waste landfills, comprising the following steps:

[0040] Step 1. Pretreatment of waste plastics: Waste plastics mainly come from domestic waste landfills, which are excavated, screened, and collected. Waste plastics are removed from impurities such as sediment and moisture by a mixer, and then transported into the factory area, and automatically processed by truck scales. After weighing, it is unloaded into the waste plastic storage bin by the unloading platform. The waste plastic storage bin is a closed hall. The transportation vehicle of waste plastic arrives at the unloading position according to the computer control, and the door is automatically opened for unloading; the mixed garbage in the waste plastic storage bin is used The bridge-type special grab machine is remotely controlled by the industrial TV set above the electric g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com