A method of smelting reduction production and quenching and tempering treatment of mixed slag

A quenching and tempering treatment, slag technology, applied in the field of mixed slag smelting reduction production and quenching and tempering treatment, can solve the problems of blast furnace ironmaking technology limitations, environmental pollution, large accumulation of steel slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

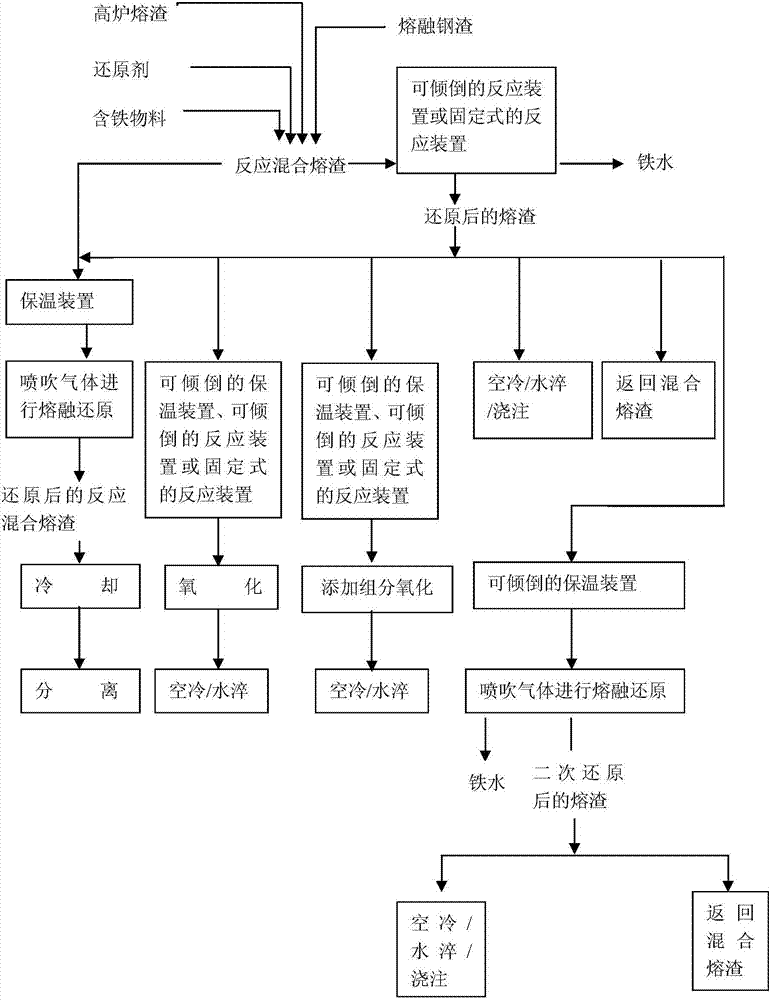

Image

Examples

Embodiment 1

[0151] A method for smelting reduction production and quenching and tempering treatment of mixed slag is carried out according to the following steps:

[0152] Step 1, smelting reduction:

[0153] (1) Material mixing and melting

[0154] Mix the ordinary blast furnace slag obtained from the blast furnace slag outlet with the converter steelmaking molten steel slag obtained from the steel slag outlet to obtain the mixed slag, and add it to the thermal insulation slag tank with graphite-dolomite composite thermal insulation refractory inside , then add coal powder and ordinary iron concentrate metallized pellets to obtain reaction mixed slag, spray into coal powder with a preheating temperature of 1200°C, heat to a molten state, and carry out smelting reduction to ensure that (a) and (b) Two parameters:

[0155] (a) The temperature of the reaction mixed slag is controlled at 1350-1600°C;

[0156] (b) Basicity CaO / SiO of reaction mixed slag 2 Ratio = 0.6 ~ 2.6;

[0157] Corr...

Embodiment 2

[0176] A method for smelting reduction production and quenching and tempering treatment of mixed slag is carried out according to the following steps:

[0177] Step 1, smelting reduction:

[0178] (1) Material mixing and melting

[0179] Mix the ordinary blast furnace slag obtained from the blast furnace slag outlet with the converter steelmaking molten steel slag obtained from the steel slag outlet to obtain the mixed slag, add it to the converter with carbon-magnesium composite thermal insulation refractory inside, and then Add bituminous coal and ordinary iron concentrate to directly reduce iron to obtain reaction mixed slag, spray into coal powder with a preheating temperature of 800°C, heat to a molten state, and carry out smelting reduction, and ensure both (a) and (b) through regulation and control parameter:

[0180] (a) The temperature of the reaction mixed slag is controlled at 1400~1600°C;

[0181] (b) Basicity CaO / SiO of reaction mixed slag 2 Ratio = 0.6 ~ 2.6;...

Embodiment 3

[0215] A method for smelting reduction production and quenching and tempering treatment of mixed slag is carried out according to the following steps:

[0216] Step 1, smelting reduction:

[0217] (1) Material mixing and melting

[0218] Mix the ordinary blast furnace slag obtained from the blast furnace slag outlet with the converter steelmaking molten steel slag obtained from the steel slag outlet to obtain the mixed slag, add it to the converter with asphalt-spinel composite thermal insulation refractory material inside, and then Add coal powder and ordinary iron concentrate carbon-containing pre-reduction pellets to obtain reaction mixed slag, spray into coal powder with a preheating temperature of 100°C, heat to a molten state, and perform smelting reduction. Ensure (a) and ( b) Two parameters:

[0219] (a) The temperature of the reaction mixed slag is controlled at 1400~1600°C;

[0220] (b) Basicity CaO / SiO of reaction mixed slag 2 Ratio = 0.6 ~ 2.6;

[0221] Corres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com