Assembly type steel beam-column mortise and tenon joint type joint structure and assembling method

A technology of node structure and steel structure, which is applied in the direction of building structure and construction, can solve the problems of welding quality being greatly affected by human factors, seismic performance, and high welding quality requirements, so as to achieve easy construction quality assurance and improve seismic performance , The effect of small construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

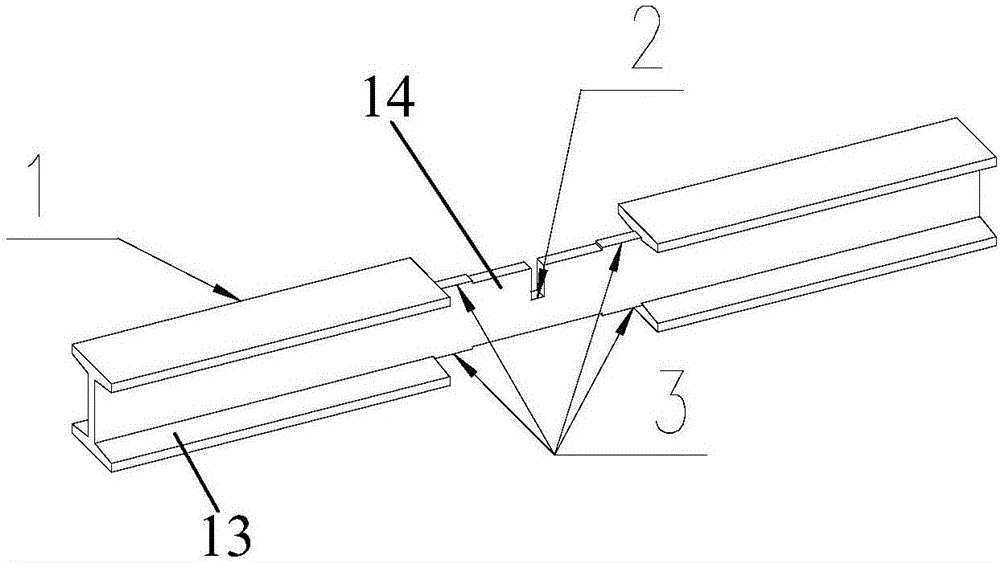

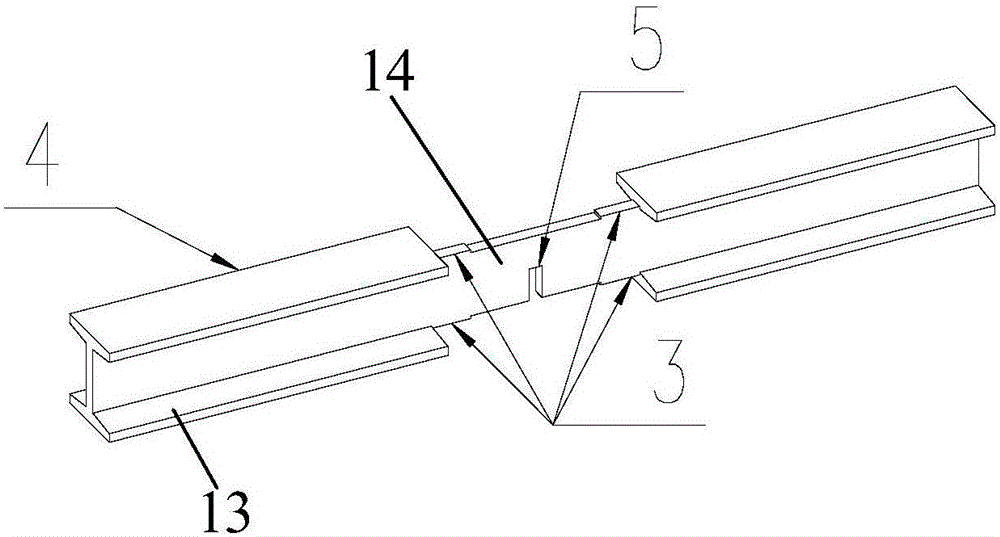

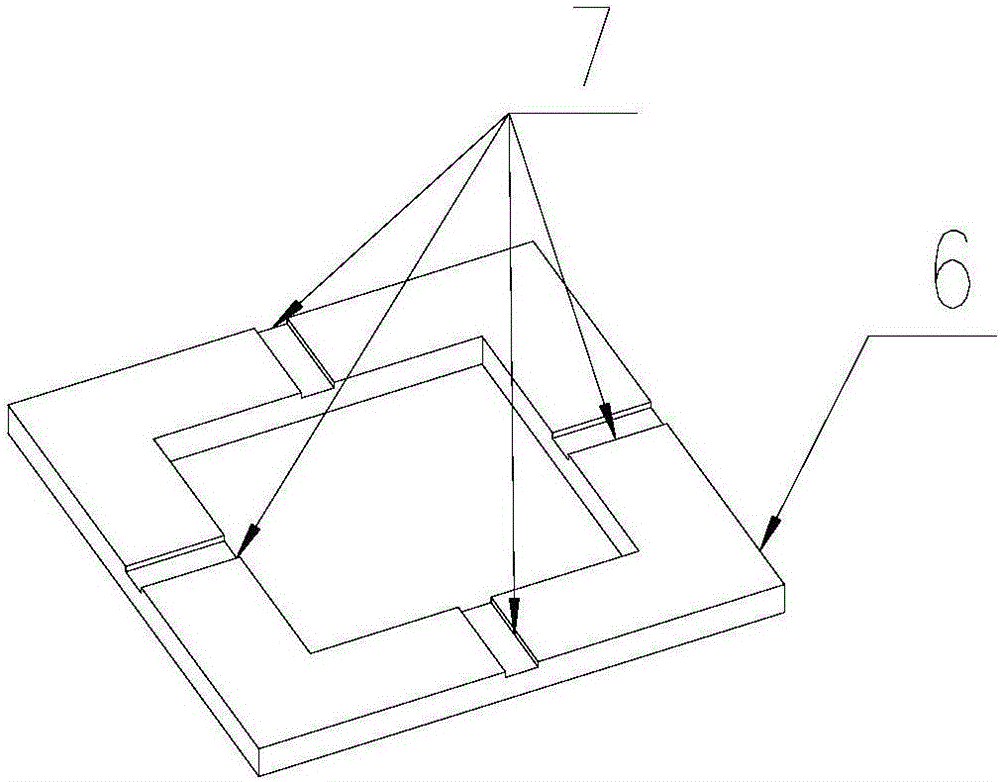

[0042] Such as Figure 1-Figure 14 As shown, the beam-column mortise and tenon joint structure of the assembled steel structure of the present invention mainly includes: orthogonal beam A1, upper slot 2, reinforcement ring snap key 3, orthogonal beam B4, lower slot 5, reinforcement ring 6, reinforcement ring Ring occlusal keyway 7, mortise and tenon steel pipe 8, tenon and tenon groove 9, mortise and tenon groove reinforcement angle steel 10, connecting steel beam 11, steel beam reinforcement angle steel 12, flange 13, web 14, etc. The specific structure is as follows:

[0043] Such as figure 1 As shown, there are flanges 13 on both sides of the orthogonal beam A1, and there is no flange in the middle part of the orthogonal beam A1, only the web 14 is reserved, and there are four reinforcing ring engagement keys 3 and upper grooves 2 on the web 14. The four reinforcing ring engagement keys 3 are respectively located at the four corners of the web 14 , and the upper groove 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com