A method for adjusting and operating steam turbine interlayer steam parameters

A technology of interlayer steam and parameter adjustment, applied in the direction of engine starting, mechanical equipment, engine components, etc., can solve the problems of flow wear, poor expansion difference of steam turbine, poor safety and reliability, etc., and reduce temperature difference, temperature field and pressure The effect of reasonable field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

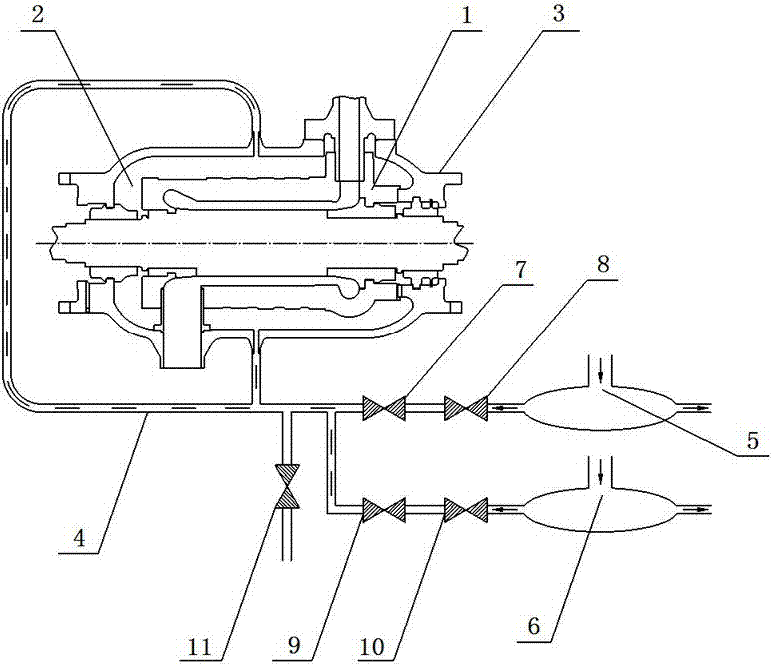

[0036] Such as figure 2 As shown, for a reheating unit, a method for adjusting and operating steam turbine interlayer steam parameters includes the following steps:

[0037] 1) The high-pressure inner cylinder 1 of the high-pressure cylinder adopts the structure of direct exhaust steam, and the high-pressure exhaust steam does not enter the interlayer 2 between the high-pressure inner and outer cylinders;

[0038] 2) One end of the pressure balance pipe 4 is connected to the interlayer 2 between the high-pressure inner and outer cylinders, and the other end is connected to the parallel steam source 1 5 and steam source 2 6; the steam source 1 5 and steam source 2 6 can all come from the inside of the steam turbine Extraction, exhaust or external steam source. The external steam source includes auxiliary steam source, start-up boiler or other steam turbine system steam.

[0039] 3) When the steam turbine is started in a cold state, open the first stop valve 8, adjust the ope...

Embodiment 2

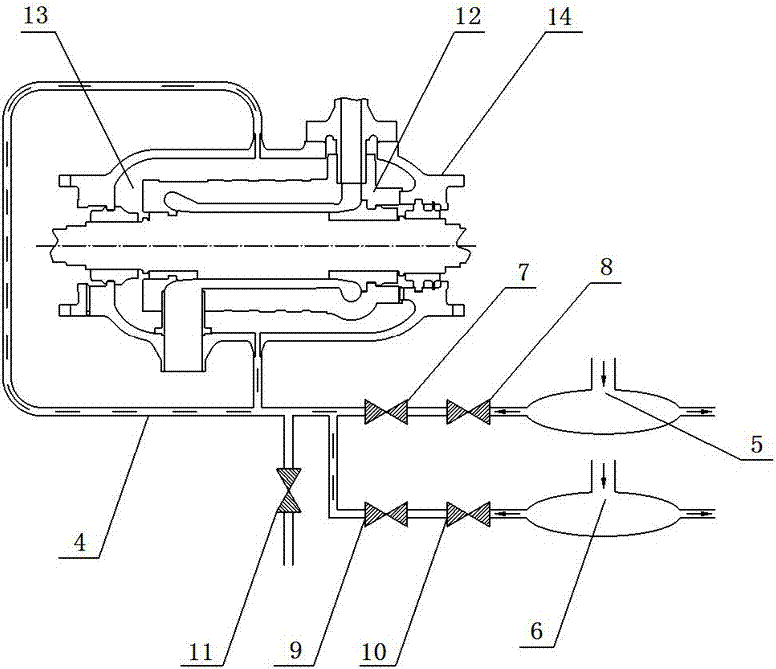

[0044] Such as image 3 As shown, for a double reheat unit, a method for adjusting and operating steam turbine interlayer steam parameters includes the following steps:

[0045] 1) The ultra-high pressure inner cylinder 12 of the ultra-high pressure cylinder adopts a direct exhaust steam structure, and the high-pressure exhaust steam does not enter the interlayer 13 between the ultra-high pressure inner and outer cylinders;

[0046] 2) One end of the pressure balance pipe 4 is connected to the interlayer 13 between the ultra-high pressure inner and outer cylinders, and the other end is connected to the parallel steam source 1 5 and steam source 2 6; the steam source 1 5 and steam source 2 6 can all come from the steam turbine Internal extraction, exhaust or external steam source. The external steam source includes auxiliary steam source, start-up boiler or other steam turbine system steam.

[0047] 3) When the steam turbine is started in a cold state, open the first stop val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com