Tower type solar concentrator system and light concentrating method

A concentrating system and solar energy technology, applied in the field of solar tower thermal power generation, can solve the problems of increasing the overall cost of the solar tower concentrating system, being unfavorable for high efficiency, and increasing complexity, so as to improve the concentrating precision and heat collection efficiency , reduce the quantity, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

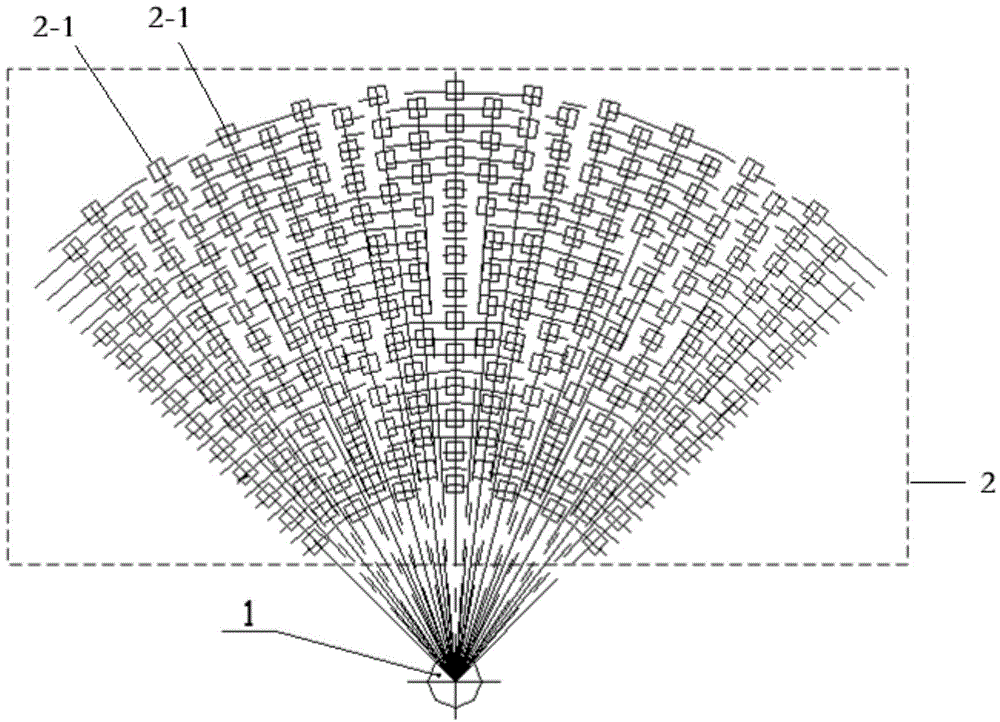

[0030] combine figure 1 and figure 2 , the present invention provides a solar tower concentrating system, including a heat collection tower 1 and a heliostat array 2; the heliostat array 2 includes n large groups of heliostats 2-1; each large group of heliostats 2-1 1 are arranged on different polar axes with the center of the heat collecting tower 1 as the pole; wherein, n is a natural number;

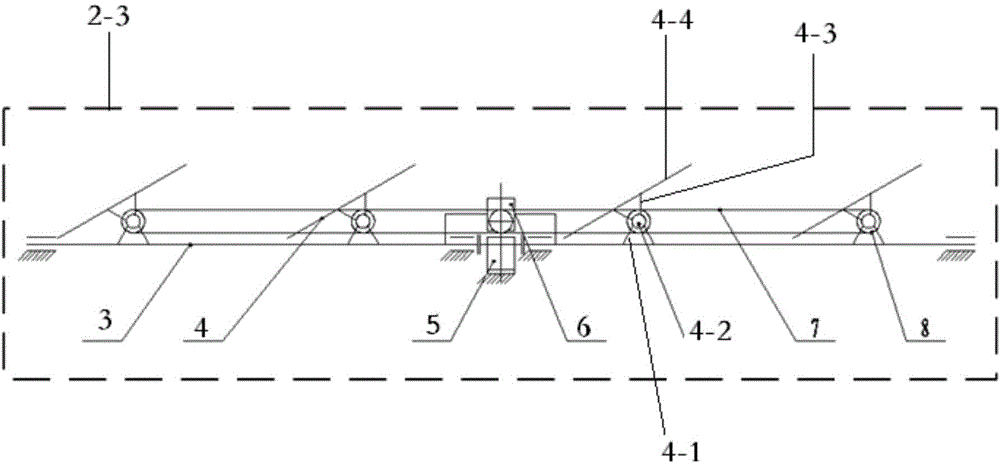

[0031] Each heliostat group 2-1 includes m heliostat groups 2-3 arranged on a polar axis; each heliostat group 2-3 includes a rotating body 3, x heliostats 4, rotating body The driving mechanism 5, the heliostat linkage transmission mechanism and the heliostat driving mechanism 6; wherein, m and x are both natural numbers;

[0032] Wherein, each heliostat 4 includes: a support frame 4-1, a support horizontal shaft 4-2, a support frame 4-3, and a reflection device 4-4; the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com