Rotary punching air compressor testing system

A test system and compressor technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of public reports and no new supersonic compressor test system, and achieve the effect of ensuring safe start and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

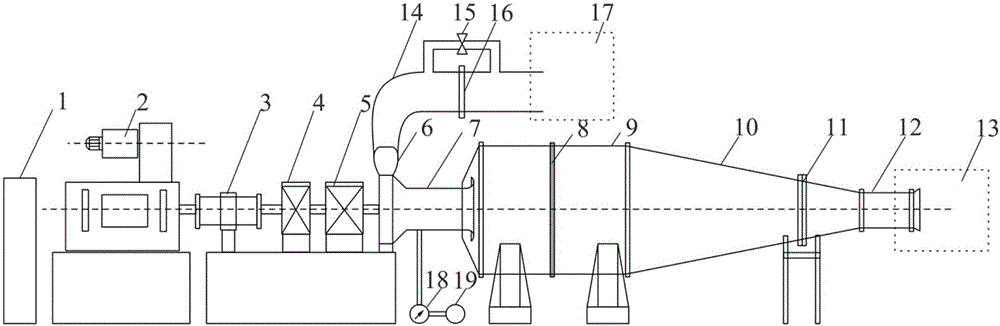

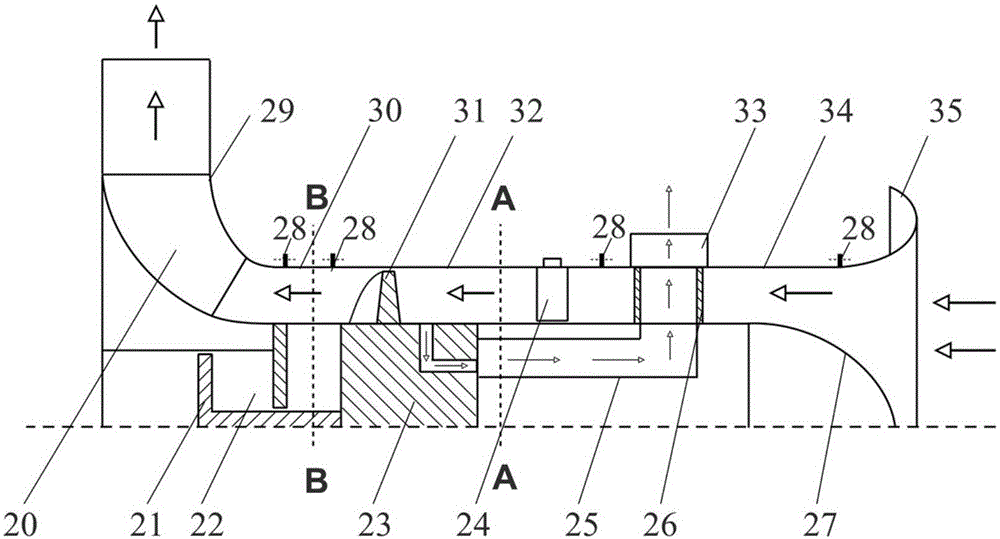

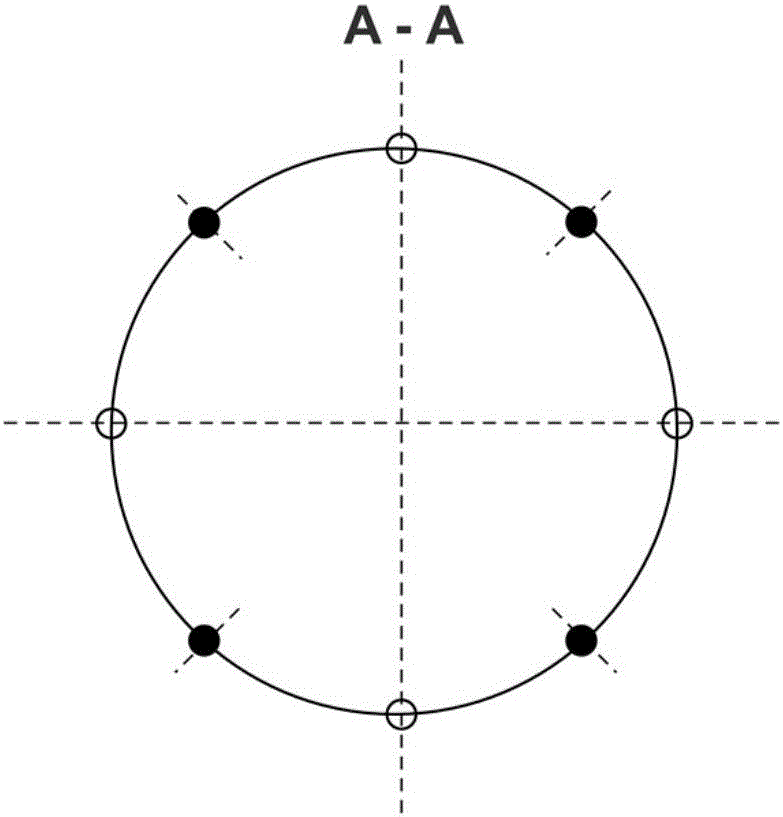

[0047] The rotary ram compressor test system of the present invention is mainly composed of a power system, a torque measuring device 3, a speed-increasing system, an intake system, an exhaust system, a rotary ram compressor test section 7, a gas discharge device, a vibration measuring device, an auxiliary system, Pneumatic parameter measurement and data acquisition system. Such as figure 1 As shown, the DC motor 2 drives the shaft system to rotate, the I-level speed increaser 4 and the II-level speed increaser 5 increase the shaft speed, and the shaft speed is stabilized at the design speed through the speed controller 1, and the rotating shaft drives the rotary stamping compression rotor Spin at high speed. The air in the air intake room 13 enters the surge tank 9 through the flow tube 12 and the diffuser section 10. When starting, the air intake throttle valve 11 is controlled at a smaller valve position, and it is gradually opened as the speed increases. Its function is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com