Method of adopting strain sensor to monitor fatigue of nuclear grade pipelines

A strain sensor and strain sensing technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc. Sexual decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

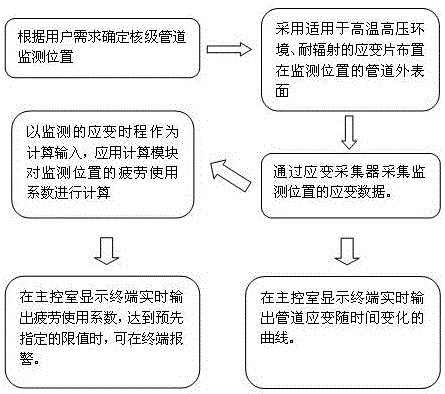

[0027] Such as figure 1 as shown,

[0028] The overall design framework of the present invention is as follows: first use strain gauges or strain gauges and other strain sensors to measure the strain on the outer surface of nuclear-grade pipelines; With the monitoring device information, determine the inner wall strain of the nuclear-grade pipeline through the heat conduction inverse problem method; then determine the alternating amplitude and the corresponding cycle number in the strain cycle, and calculate the fatigue service factor according to the preset ε-N curve; then according to Determining a reasonable environmental impact factor F through pipeline strain history en , modify the fatigue use coefficient; finally, output the fatigue use coefficient on the display terminal in the main control room, and can output the cumulative fatigue use coefficient curve changing with time, which is used to evaluate the change trend of the cumulative fatigue use coefficient at the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com