Temperature characteristic testing apparatus for Young modulus of metal wire and testing method thereof

A technology of temperature characteristics and Young's modulus, which is applied in the field of metal material test equipment, can solve difficult problems such as power consumption feeding temperature, control, and temperature characteristics that do not involve the Young's modulus of metal wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

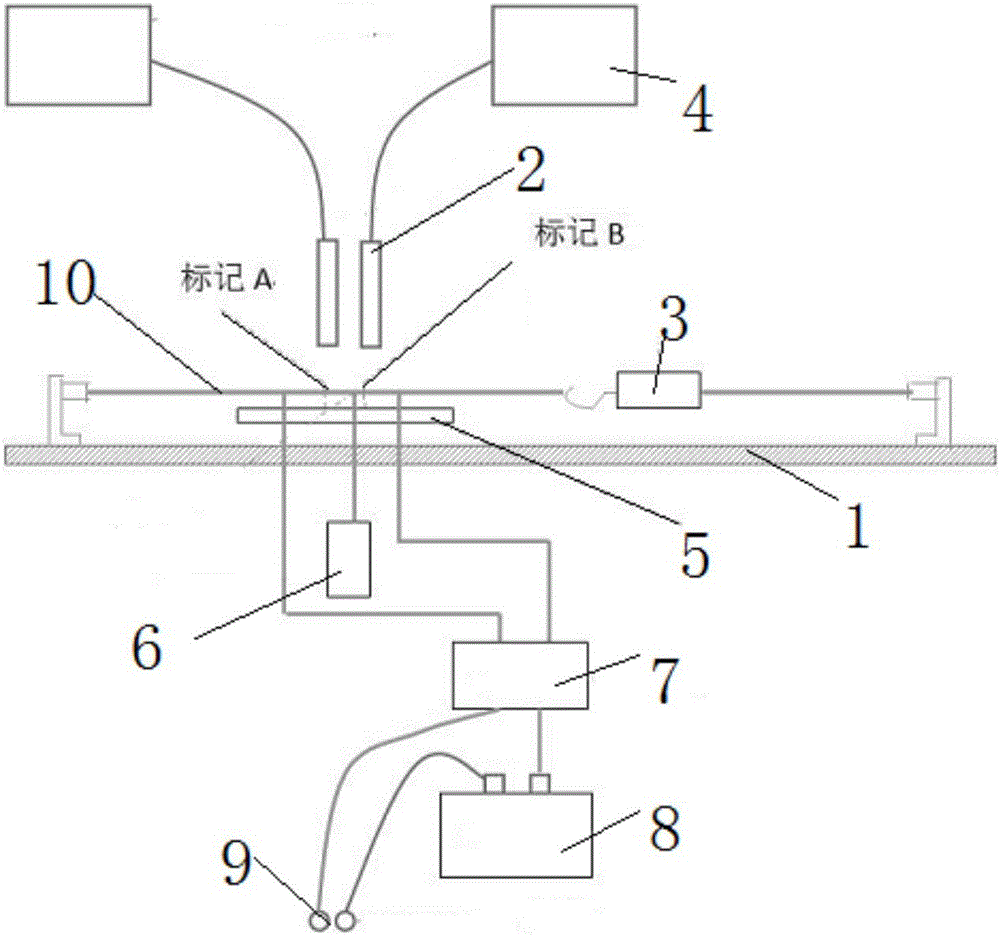

[0030] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

[0031] Such as figure 1 As shown, the temperature characteristic test device for Young's modulus of metal wire comprises a fixed frame 1, one end of the metal wire 10 is fixed on one end of the fixed frame 1, the other end of the metal wire 10 is connected with an electronic portable scale 3, and the electronic portable scale 3 is connected to the The other end of the fixing frame 1 tightens the metal wire 10 under force; in the experimental area of the metal wire 10, a digital microscope 2 is respectively arranged on the edge of the experimental area, and the digital microscope 2 is connected with the computer 4; a steel ruler is also installed in the experimental area 5; the probe of the dual-channel digital thermometer 6 is connected in the middle of the metal wire 10 experimental area; the outer ends of the experimental area of the metal wire 10 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com