Test method and establishment method of thermoforming wrinkling limit surface based on this method

A hot forming and stamping test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, to achieve the effect of ingenious design and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

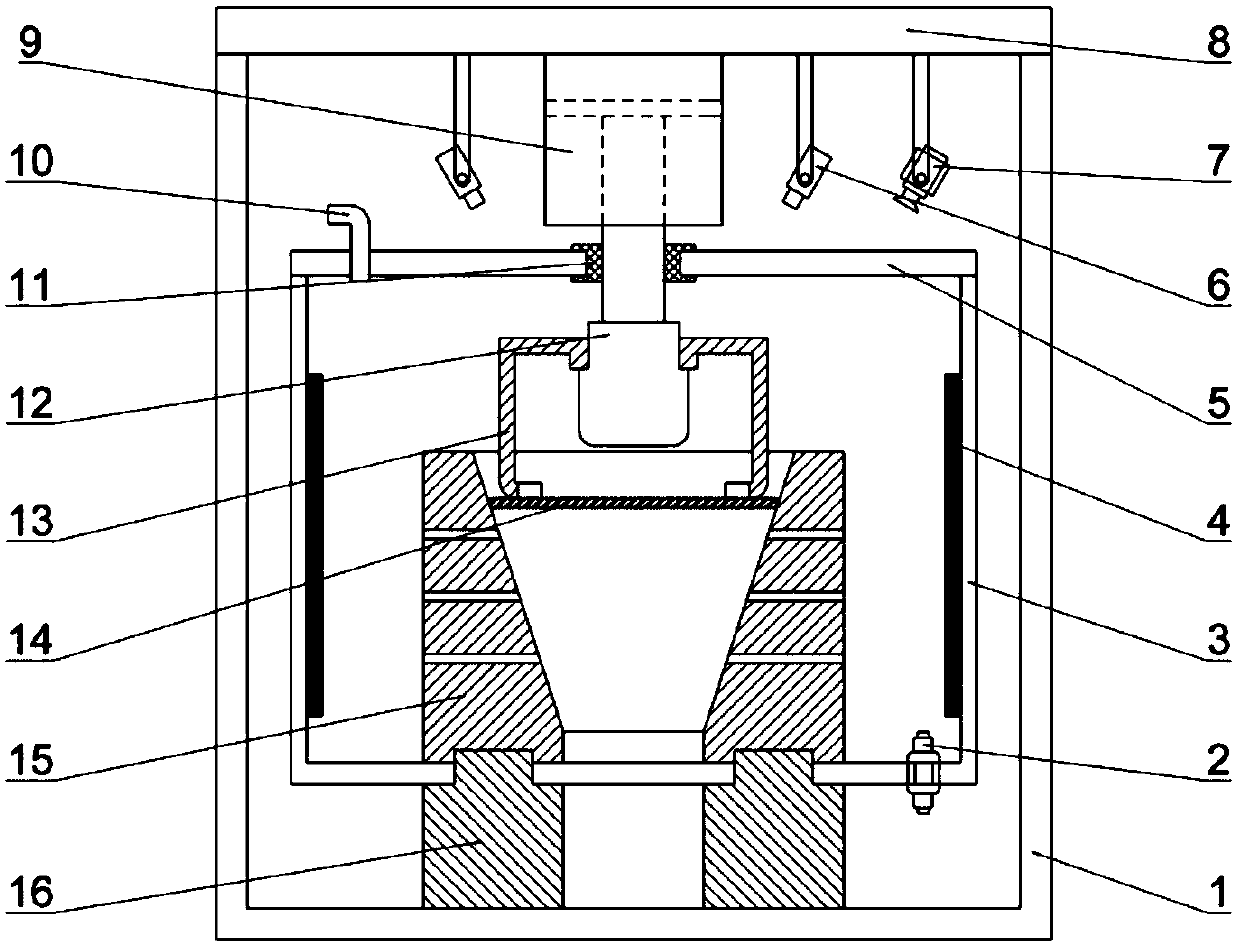

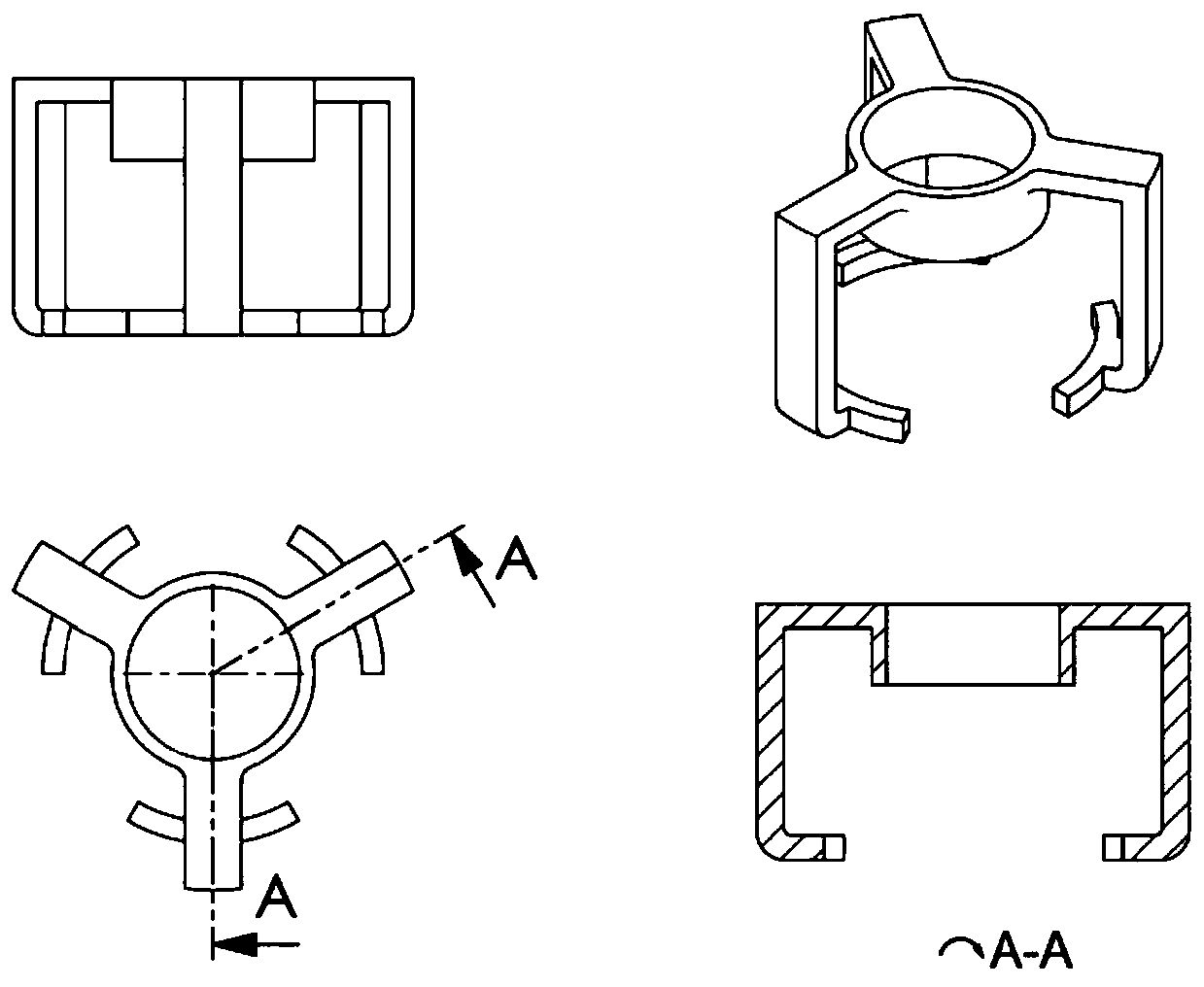

[0042] Attached below Figure 1-8 The technical solution of the present invention is described in detail.

[0043] In order to obtain the thermoforming wrinkling limit line, maintain a stable temperature during the heat preservation and test stages, and prevent excessive oxidation of high-strength steel, the present invention provides a thermoforming stamping test device for high-strength metal sheets, which includes: support 1, gas One-way valve 2, sealing box 3, resistance wire 4, quartz glass 5, high-speed camera 6, infrared temperature sensing device 7, bracket top cover 8, punch hydraulic pump 9, breather pipe 10, punch hydraulic pump connecting rod sealing ring 11. Punch 12, positioning ring 13, test piece 14, die 15, sealing box support 16.

[0044]Wherein, the sealing box support 16 and the support 1 are welded on the base. Both ends of the die 15 have grooves for matching with the seal box support and positioning the die 15 . The locating ring 13 and the punch are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com