Cross pollution-free sample introduction device and control method thereof

A sampling device and cross-contamination technology, which is applied in the field of sampling devices without cross-contamination, can solve the problems affecting the accuracy of test analysis and cross-contamination, and achieve the effects of easy popularization, convenient operation, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further clarify the technical scheme and design principle of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

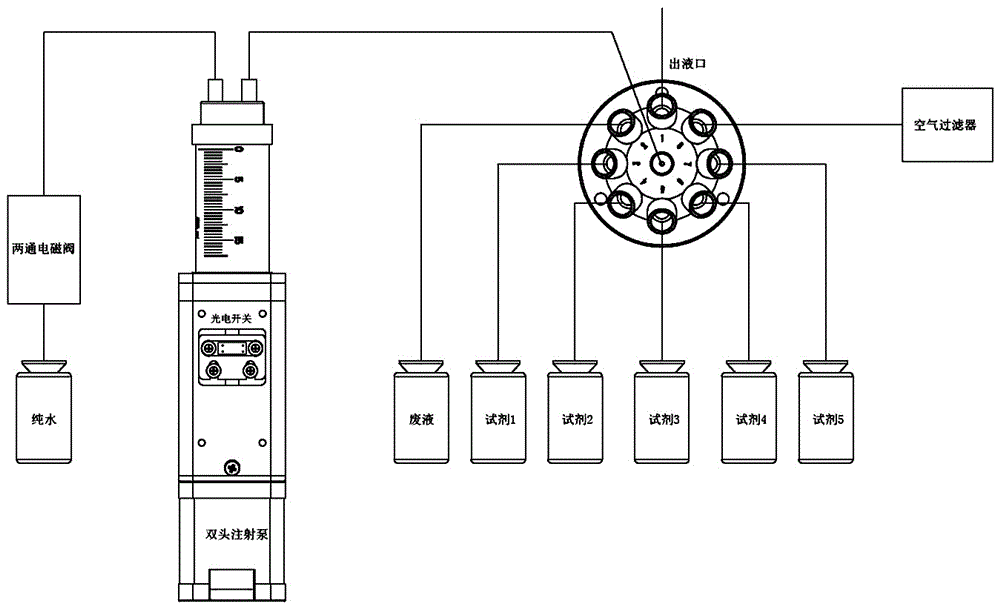

[0029] Such as figure 1 As shown, a cross-contamination-free sampling device includes a syringe pump, a multi-way valve, a cleaning solution container, a reagent container, a waste liquid container, and connecting pipelines.

[0030] The syringe pump is a double-headed syringe pump, which is provided with a liquid chamber, a piston, a drive mechanism that drives the piston to reciprocate, and a first nozzle and a second nozzle for liquid in and out. The nozzle is connected to the cavity of the injection pump, and the first nozzle is connected to the cleaning solution container through the first pipeline. The first control valve is provided on the first pipeline to control the on-off of the pipeline, preferably a two-way solenoid valve. Pure water as...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap