Alloy fuse

A fuse and alloy technology, applied in electrical components, circuits, emergency protection devices, etc., can solve the problems of difficult control of the size of the alloy effect point at welding temperature, poor consistency of alloy fuses, and inability to achieve precise fusing, etc., and achieve fusing characteristics. The effects of control, power consumption reduction, and product safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the specific embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

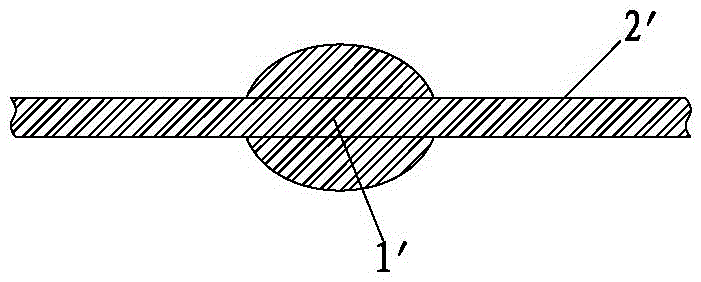

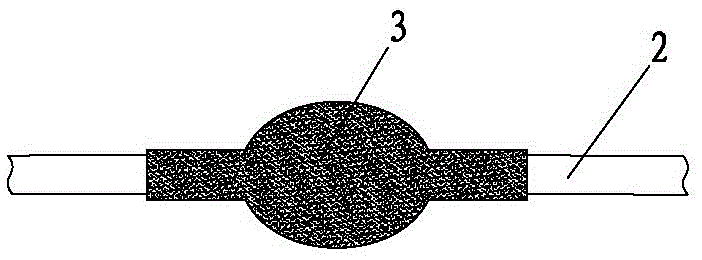

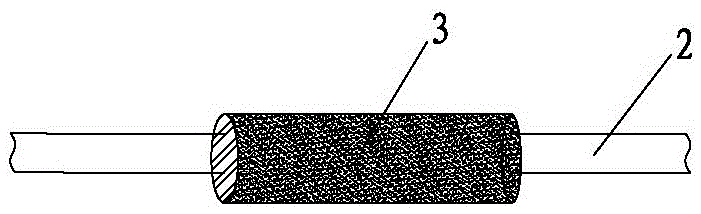

[0030] Such as Figure 2~6 As shown, an alloy fuse includes an alloy effect point 1 and a wire 2 connected to both ends of the alloy effect point 1, wherein the diameters of the wires 2 at both ends are equal, and the alloy effect point 1 is a flat sheet-shaped fuse, and the fuse The thickness of the fuse is 6 / 10~9 / 10 of the diameter of the wire 2, and the fuse piece is set in a flat shape, so that the fusing characteristics of the fuse are easier to control.

[0031] The fuse link is provided with several through holes 11, wherein the aperture size of the through hole 11 is 0.1~10mm, and the porosity is 40~80%. If the aperture or porosity is too small, the breaking capacity of the fuse link will be weakened, which is not conducive to Timely fusing; if the pore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com