Mark, display apparatus, and method for monitoring exposure and etching process stability by use of mark

A display device and stability technology, applied in the field of TFT manufacturing, can solve problems such as slenderness, affecting process stability, product quality, process fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the general Cu process product design, since all the metal traces inside the effective area will gather and gather at various pads in the peripheral fan-out area, resulting in dense and slender out-of-plane traces, this part of the area is prone to etching Endless questions.

[0017] Therefore, in one aspect of the present invention, a mark for monitoring the stability of the exposure and etching process is set on the transition area between the display area and the non-display area. By monitoring this mark, the peripheral metal traces can be scientifically and effectively monitored. The exposure and etching conditions of the line, and the stability of the exposure and etching process can be monitored at the same time.

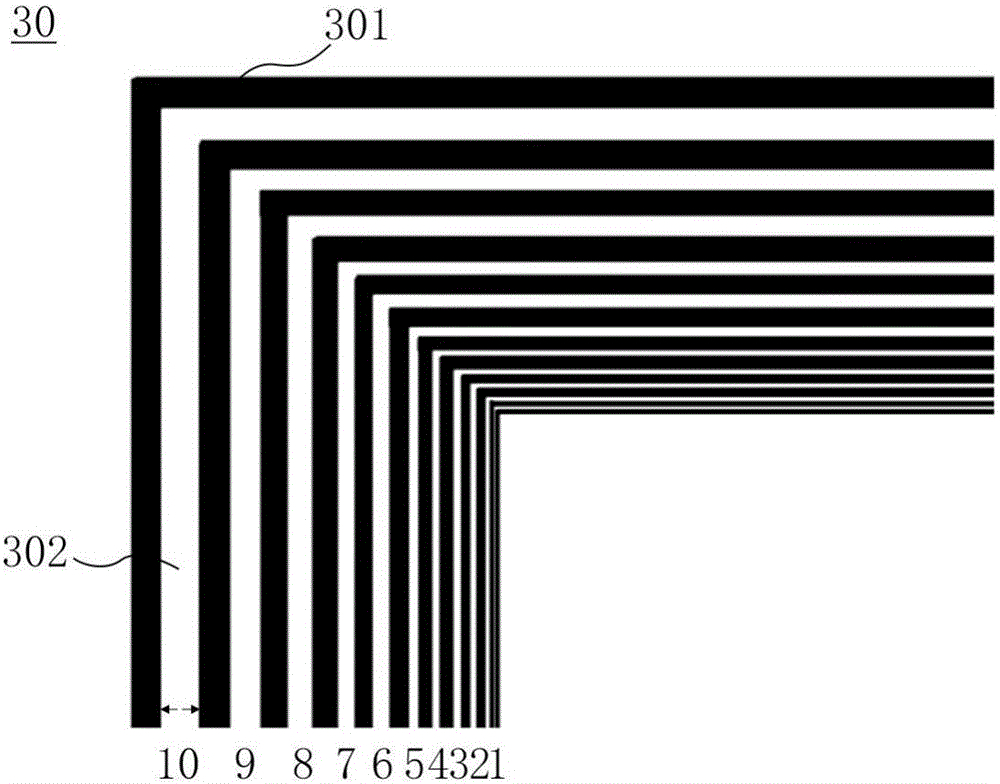

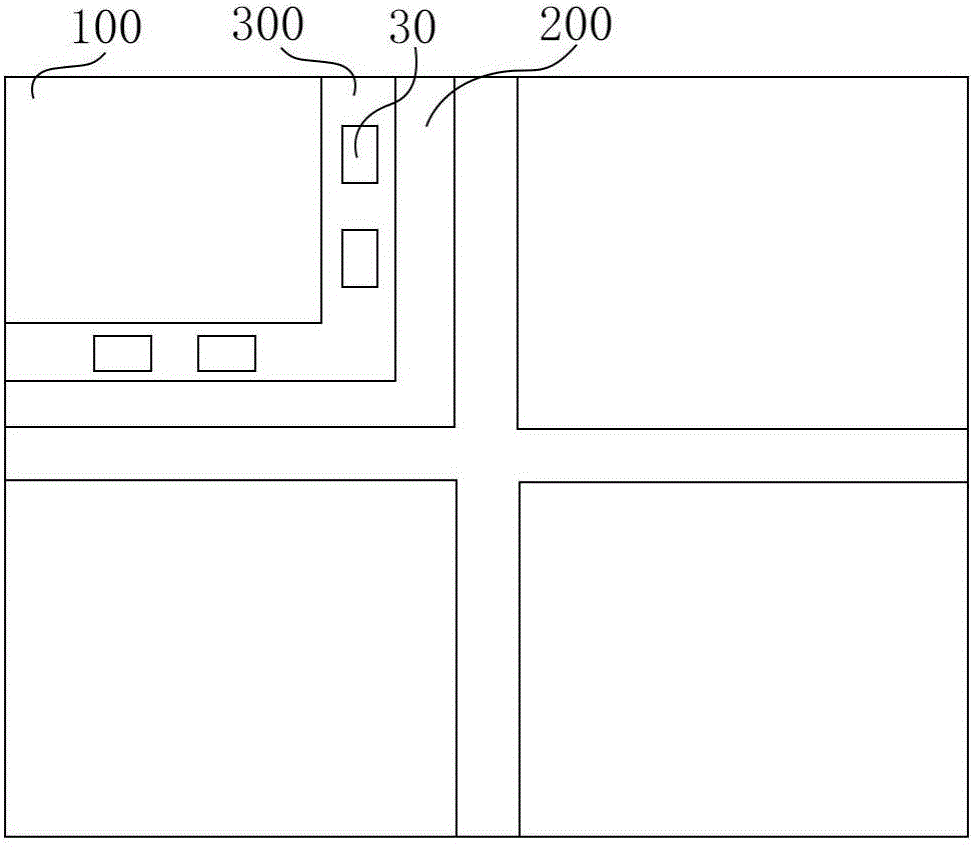

[0018] figure 1 is a diagram schematically showing marks for monitoring exposure and etching process stability according to an exemplary embodiment of the present invention; figure 2 It is a layout view schematically showing the marks for monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com