Stator for electric car hub motor and motor containing the same

A technology for in-wheel motors and electric vehicles, applied in the field of electric vehicles, can solve the problems of structural changes of electric vehicles, low motor conversion efficiency, and sharp increase in motor failure rate, so as to increase the area of stator slots, prevent the failure of Hall position sensors, Improve the effectiveness of the efficiency platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

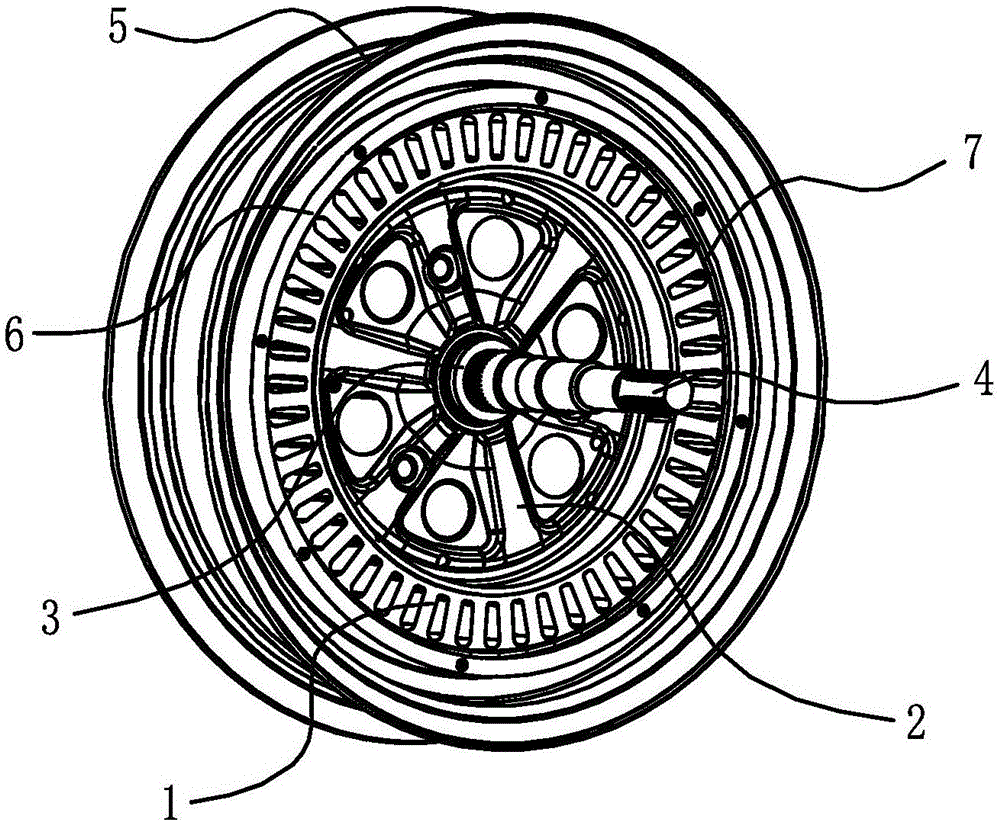

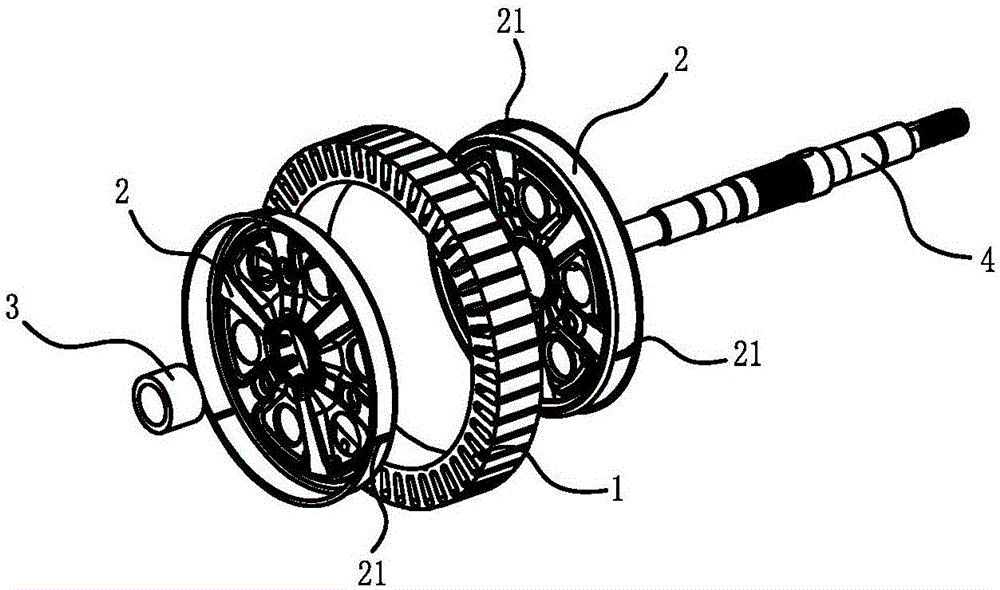

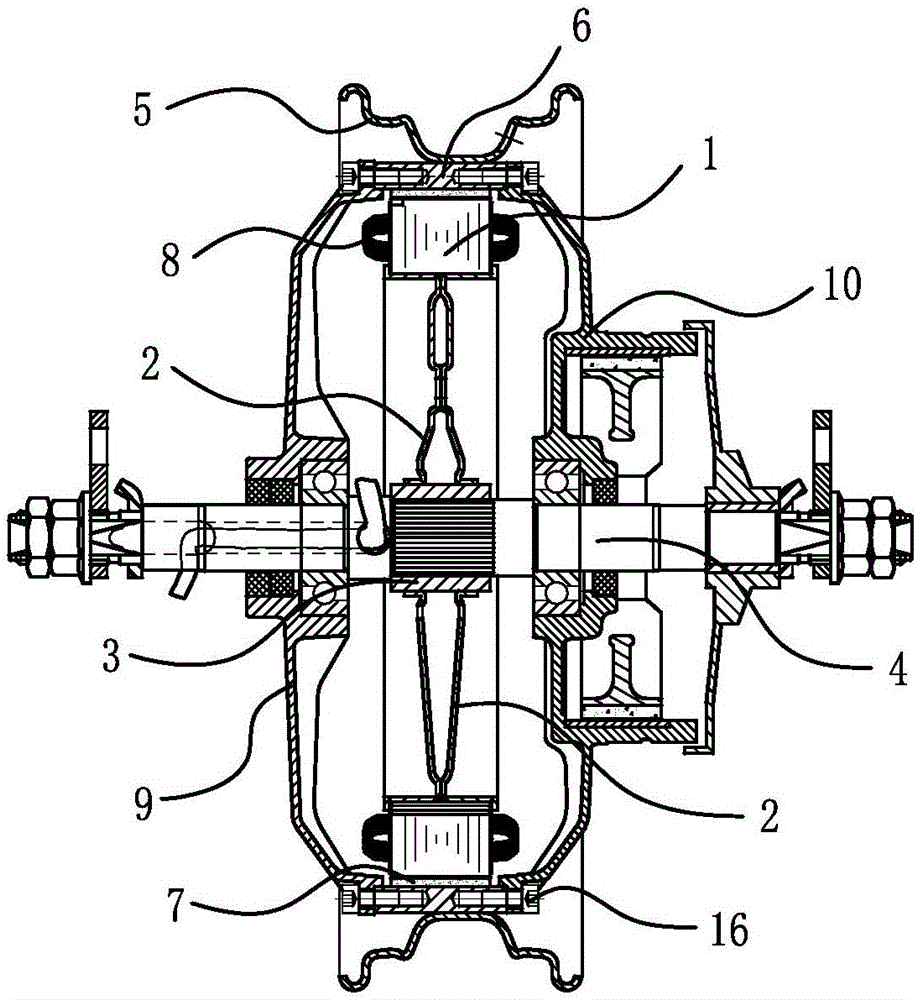

[0041] Such as Figure 1 to Figure 5 As shown, a 10-inch electric wheel hub motor stator provided in this embodiment includes a stator core 1 and a bracket 2, the stator core 1 is fixed on the bracket 2, and the stator core 1 is formed by laminating several stator pieces. As a result, a copper wire winding 8 is wound on the stator core 1 . In this embodiment, two above-mentioned brackets 2 with the same shape are used to fix the stator core 1 between the two brackets 2 by crimping. A mounting hole is provided in the center of the bracket 2, and a shaft sleeve 3 is pierced in the mounting hole. The stator core 1 is provided with anti-rotation grooves 15, and the bracket 2 is provided with anti-rotation ribs 21. The above-mentioned anti-rotation grooves 15 and anti-rotation ribs 21 correspond one-to-one, which can ensure that the stator will be under the action of electromagnetic shear force when the motor rotates. It will not rotate with it. In this embodiment, the structure ...

Embodiment 2

[0063] The technical solutions in this embodiment are mostly the same as those in Embodiment 1. This embodiment only describes the different parts in detail, and the parts that are the same as those in Embodiment 1 will not be repeated here.

[0064] The outer diameter of the stator core 1 is 205.01-212 mm, preferably, the outer diameter of the stator core 1 is 206-210 mm, the notch width A2 of the stator core slot is related to the outer diameter of the stator core, the inner diameter of the stator core, and the yoke of the stator core The internal thickness A3 and the number of stator core slots satisfy the following relationship:

[0065] In this embodiment, the structure of the stator is a structure of 48 slots and 44 pieces of permanent magnets. The notch width A2 of the stator core slot = (α + the value of the thickness of the single-layer silicon steel sheet of the stator core) × π × (outer diameter of the stator core-inner diameter of the stator core-thickness of the y...

Embodiment 3

[0068] In this embodiment, the structure of the stator is a structure of 48 slots and 52 pieces of permanent magnets. The technical solutions in this embodiment are mostly the same as those in Embodiment 1. This embodiment only describes the different parts in detail, and the parts that are the same as those in Embodiment 1 will not be repeated here.

[0069] The outer diameter of the stator core 1 is 205.01 to 212 mm, preferably, the outer diameter of the stator core 1 is 205.5 to 211 mm, and the notch width A2 of the stator core slot is related to the outer diameter of the stator core, the inner diameter of the stator core, and the yoke of the stator core The internal thickness A3 and the number of stator core slots satisfy the following relationship:

[0070] The notch width A2 of the stator core slot = (α + the value of the thickness of the single-layer silicon steel sheet of the stator core) × π × (outer diameter of the stator core-inner diameter of the stator core-thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com