Linear Vibration Motor

A technology of linear vibration and vibration direction, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of low BL value and small magnetic field in the magnetic circuit, and achieve the effects of reducing magnetic flux leakage, increasing magnetic field strength, and increasing magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

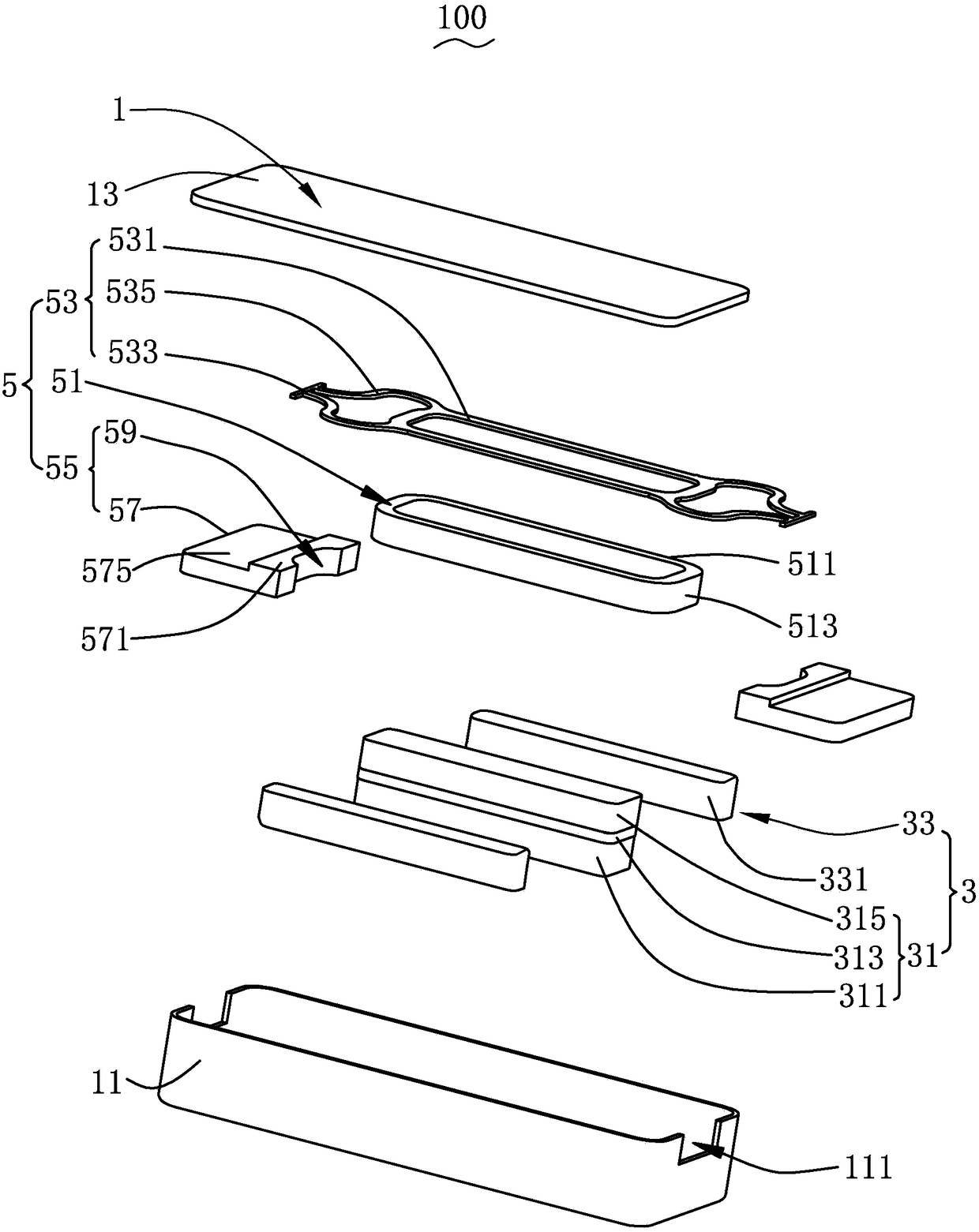

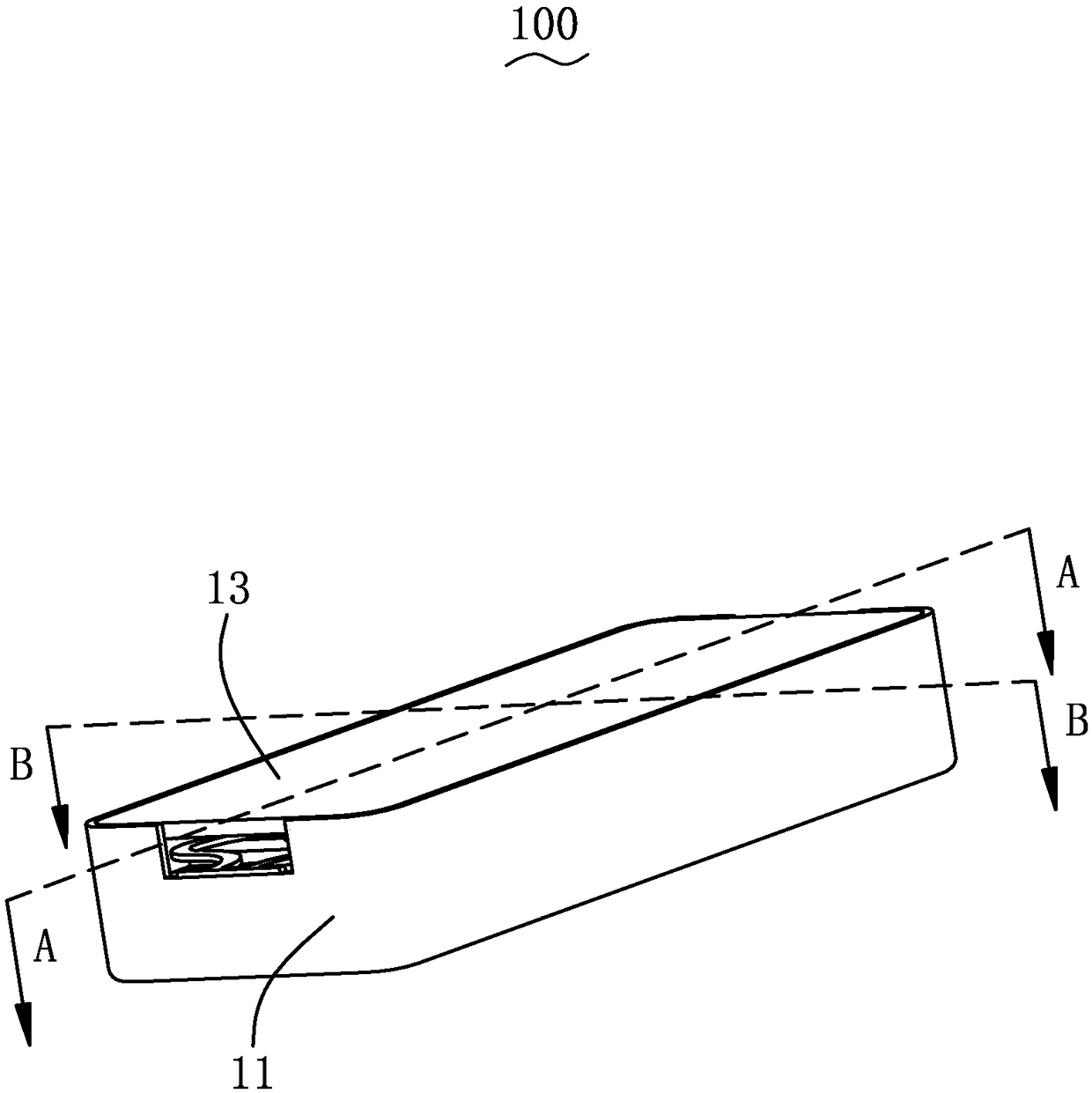

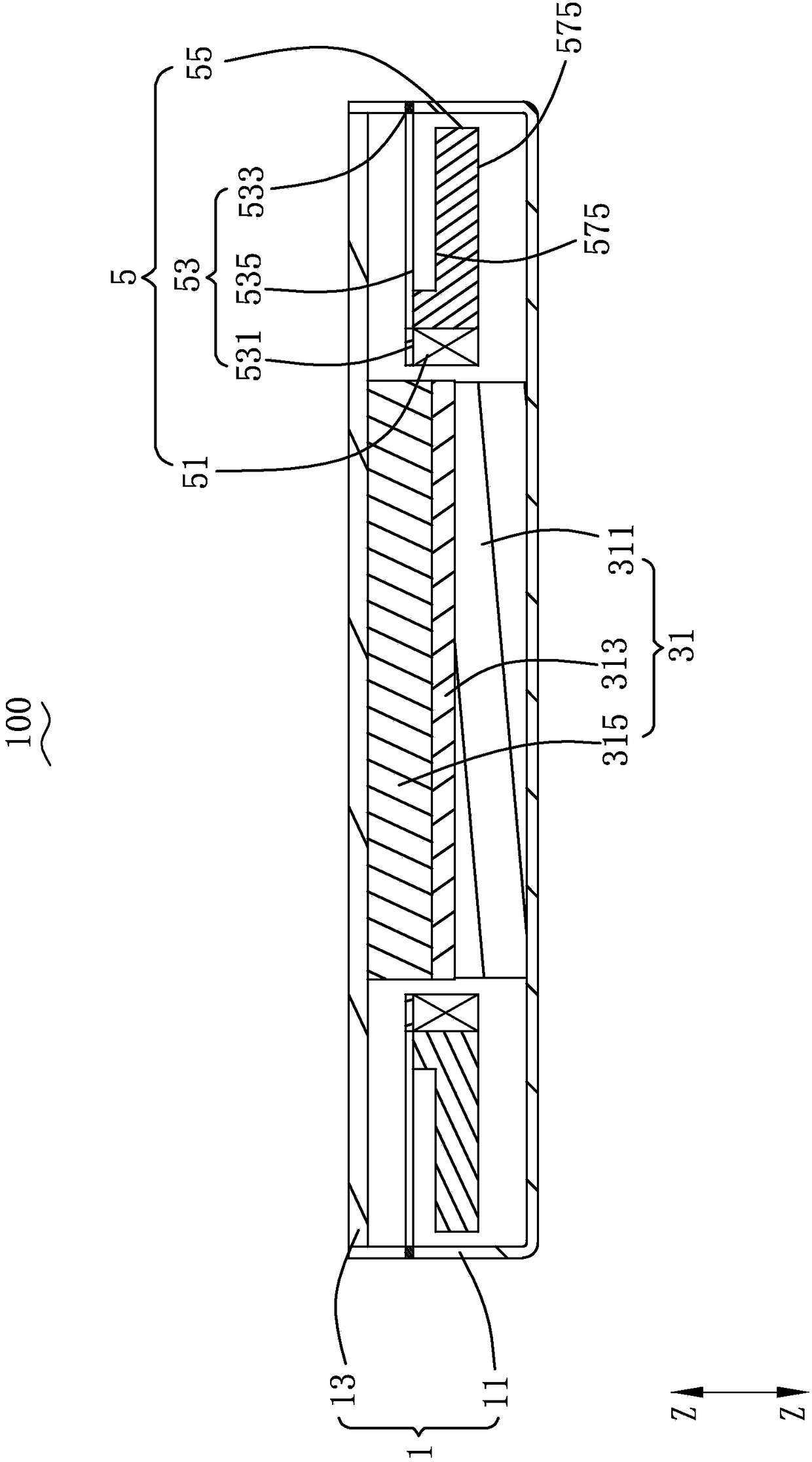

[0027] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 An exploded view of the three-dimensional structure of the linear vibration motor provided by the present invention, figure 2 for figure 1 The schematic diagram of the assembled structure of the linear vibration motor shown, image 3 for figure 2 The sectional view of the shown linear vibration motor along the direction A-A, Figure 4 for figure 2 The cross-sectional view of the linear vibration motor shown along the B-B direction. The present invention provides a linear vibration motor 100, which includes a housing 1 with a housing space, a magnetic circuit system 3 and a vibrator system 5 fixed in the housing 1, and the magnetic circuit system 3 drives the vibrator system 5 Vibrates along the Z-Z direction.

[0028] The casing 1 is made of soft magnetic material, and includes a casing 11 and a cover 13 assembled with the casing 11 to form a receiving space.

[0029] The housing 1...

Embodiment 2

[0042] see Figure 5 , is a cross-sectional view of Embodiment 2 of the linear vibration motor provided by the present invention. The difference between the second embodiment and the first embodiment is that the secondary magnetic circuit system 33 ′ of the linear vibration motor 200 further includes a fourth magnetic steel 333 ′ attached to the third magnetic steel 331 ′ along the Z-Z direction. The fourth magnetic steel 333' is magnetized along the Z-Z direction, and the polarity of the magnetic pole of the fourth magnetic steel 333' close to the third magnetic steel 331' is the same as that of the first magnetic steel 311'. The polarity of the magnetic poles of the core 313' is reversed. Specifically, when the opposite arrangement of the same poles of the first magnet 311' and the second magnet 315' is N-S-S-N, the N pole of the fourth magnet 333' is attached to the The third magnetic steel 331'; when the same polarity relative arrangement of the first magnetic steel 311'...

Embodiment 3

[0047] see Figure 6 , is a cross-sectional view of the third embodiment of the linear vibration motor provided by the present invention. The difference between the third embodiment and the second embodiment is that the secondary magnetic circuit system 33″ of the linear vibration motor 300 also includes The fifth magnet is 335″. The fifth magnetic steel 335 ″ is magnetized along the Z-Z direction, and the fifth magnetic steel 335 ″ and the fourth magnetic steel 333 ″ are oppositely arranged with the same pole.

[0048] In this embodiment, the fifth magnet 335″ is the same magnet as the fourth magnet 333″, and the fourth magnet 333″ is away from the fifth magnet 335″. The surface of the fifth magnetic steel 335 ″ is attached to the bottom of the housing 11 ″, and the surface of the fifth magnetic steel 335 ″ away from the fourth magnetic steel 333 ″ is attached to the cover 13 ″.

[0049] Compared with Embodiment 2, in Embodiment 3, the two third magnetic steels 331″ are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com