Vehicular micro-vacuum fruit-vegetable picking field cooling device and pre-cooling method thereof

A cooling device, fruit and vegetable technology, applied in fruit and vegetable preservation, food preservation, food science and other directions, to achieve the effect of short pre-cooling time, excellent comprehensive performance, and overcoming no electricity and no power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

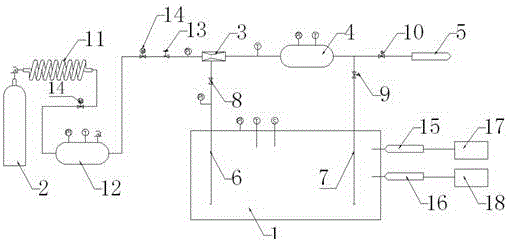

[0032] A vehicle-mounted micro-vacuum fruit and vegetable picking on-site cooling device, the pre-cooling effect is between differential pressure pre-cooling and vacuum pre-cooling, including a micro-vacuum box 1 and a liquid nitrogen cylinder 2 connected in sequence through a gas pipe, a vaporization decompression device, a vacuum Generator 3, gas storage tank 4 and exhaust pipe 5.

[0033] Wherein, the opposite sides of the inside of the micro-vacuum box 1 are respectively provided with an air extraction pipe 6 and an air return pipe 7, the vacuum generator 3 communicates with the air extraction pipe 6 through a gas pipe equipped with a check valve 8, and the gas storage tank 4 is installed with a The air pipe of the first electromagnetic valve 9 communicates with the air return pipe 7 . Arranging the exhaust pipe and the air return pipe on both sides of the micro-vacuum box indirectly achieves the effect of differential pressure pre-cooling. In addition, vacuuming the micro...

Embodiment 2

[0042] The difference from Embodiment 1 is that one side of the micro-vacuum box 1 is also connected with a constant temperature air duct 15 and a constant humidity air duct 16, and the refrigeration system 17 and the humidification system are respectively connected through the constant temperature air duct 15 and the constant humidity air duct 16 18, so as to record the pre-cooling data of different kinds of fruits to provide customers with experimental data of different kinds of fruits.

[0043] The advantages of the vehicle-mounted micro-vacuum picking site precooling device of the present invention are as follows:

[0044] 1. No power supply is needed, which solves the problem of no power supply at some picking sites.

[0045] 2. There are no special requirements for packaging and stacking, effectively improving stacking efficiency and reducing transportation costs.

[0046] 3. The cooling time is short and the speed is fast, only 20-30 minutes.

[0047] 4. Make full use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com