Paying-off and cutting integrated machine for corrugated pipes

A corrugated tube and integrated machine technology, applied in the field of corrugated tube pay-off and cutting integrated machine, can solve the problems of uneven quality of finished products, poor quality of corrugated tube cut surface, difficult quality guarantee, etc., and achieve high precision, high work efficiency, and structural Simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

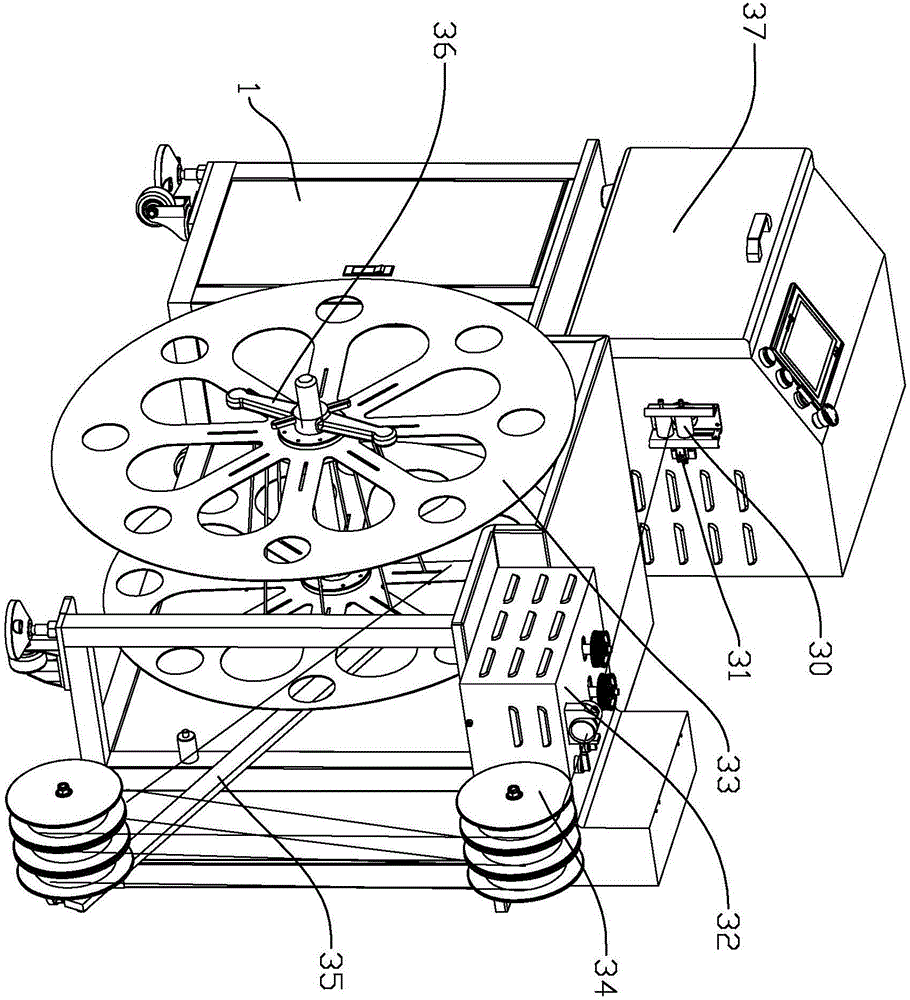

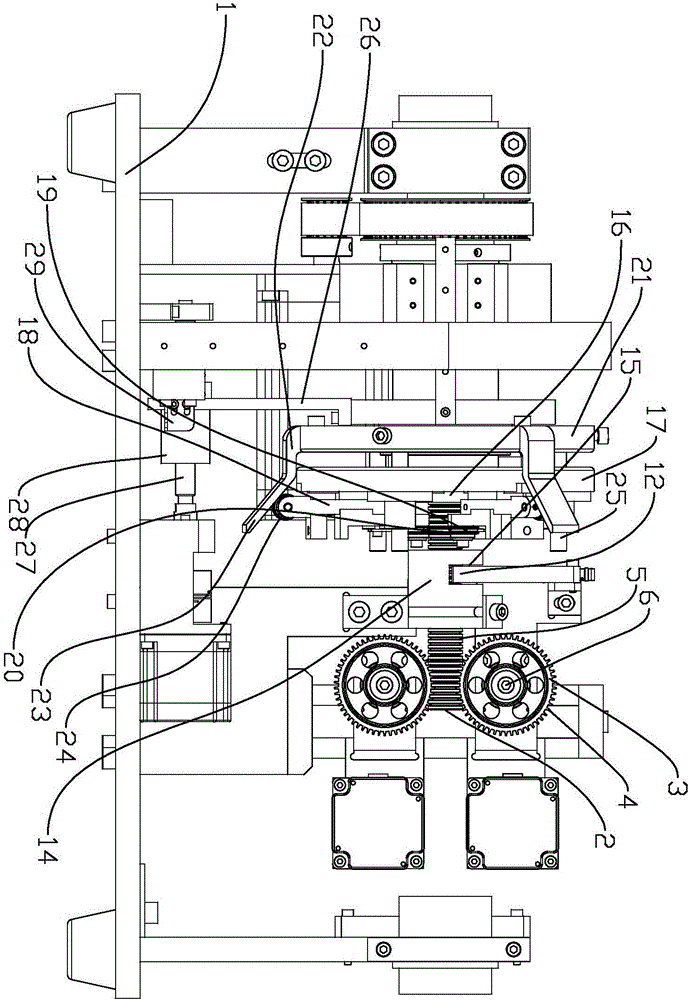

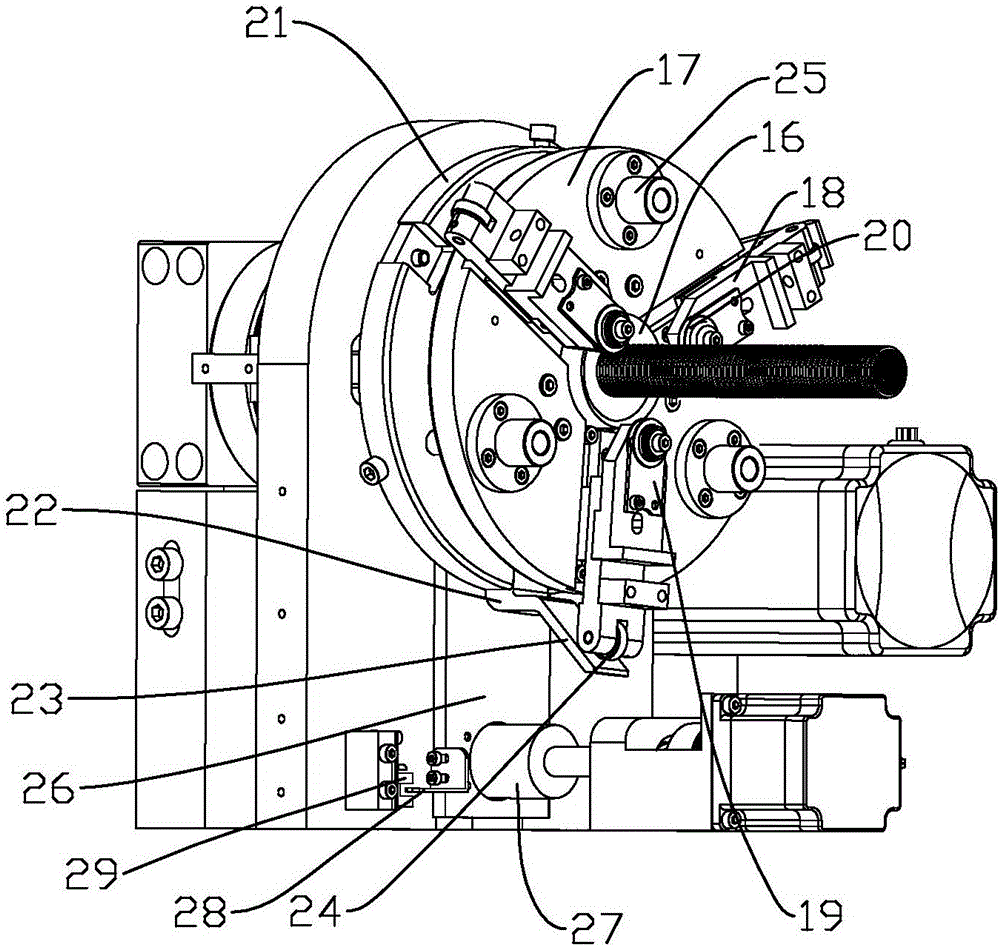

[0030] refer to Figure 1 to Figure 6 , the present invention is an all-in-one bellows wire cutting machine including:

[0031] Frame 1, a discharge device is arranged on the frame, which is used for storing and conveying the bellows outward, and controlling the discharge speed of the bellows;

[0032] The feeding device is docked with the discharging device and is arranged on the frame to drive the bellows 2 to move forward and control the bellows to be in a natural state;

[0033] The length measuring device is arranged on the frame 1 and is used to measure the length of the corrugated pipe 2 passing through;

[0034] The cutting device is arranged on the frame 1 and connected with the length measuring device for cutting the bellows 2 according to the set size. The present invention adopting the above structure can realize stable feeding of the bellows 2, automatic detection of the length of the passing bellows 2, and cutting of the bellows 2 according to the set size, wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com