Repair and maintenance device

A maintenance device and repairing technology, which is applied in the direction of spraying device, spraying device, packaging material feeding device, etc., can solve the problems of increased project cost, complex structure, large volume, etc., and achieve the effect of preventing foaming or wrinkles and repairing Good, good wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

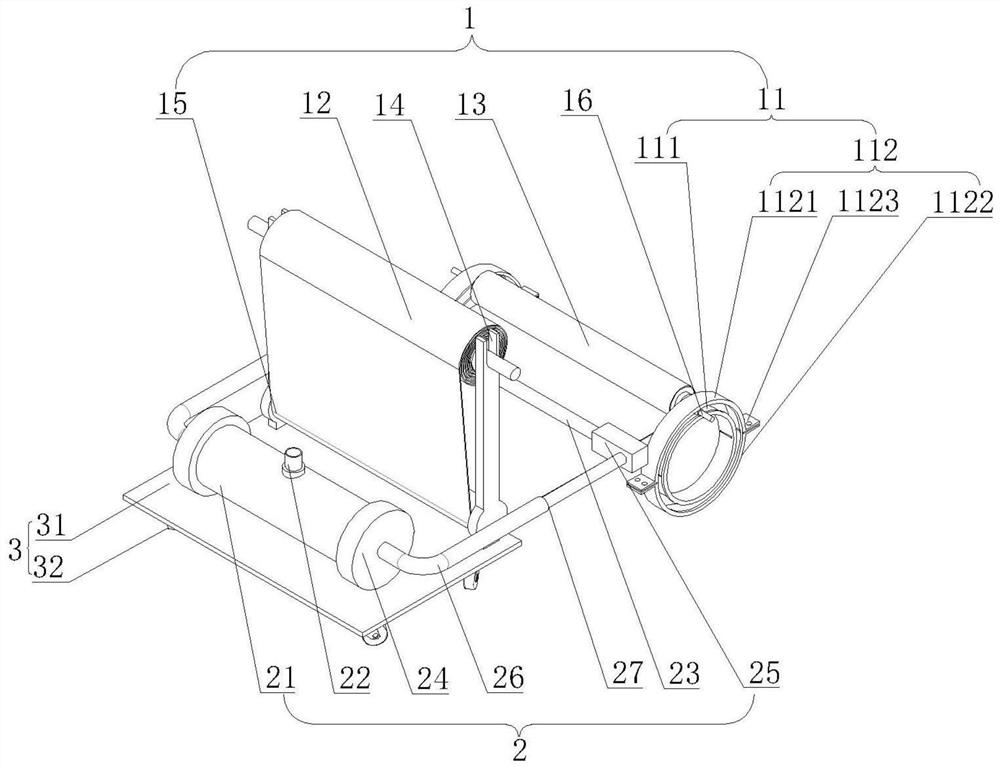

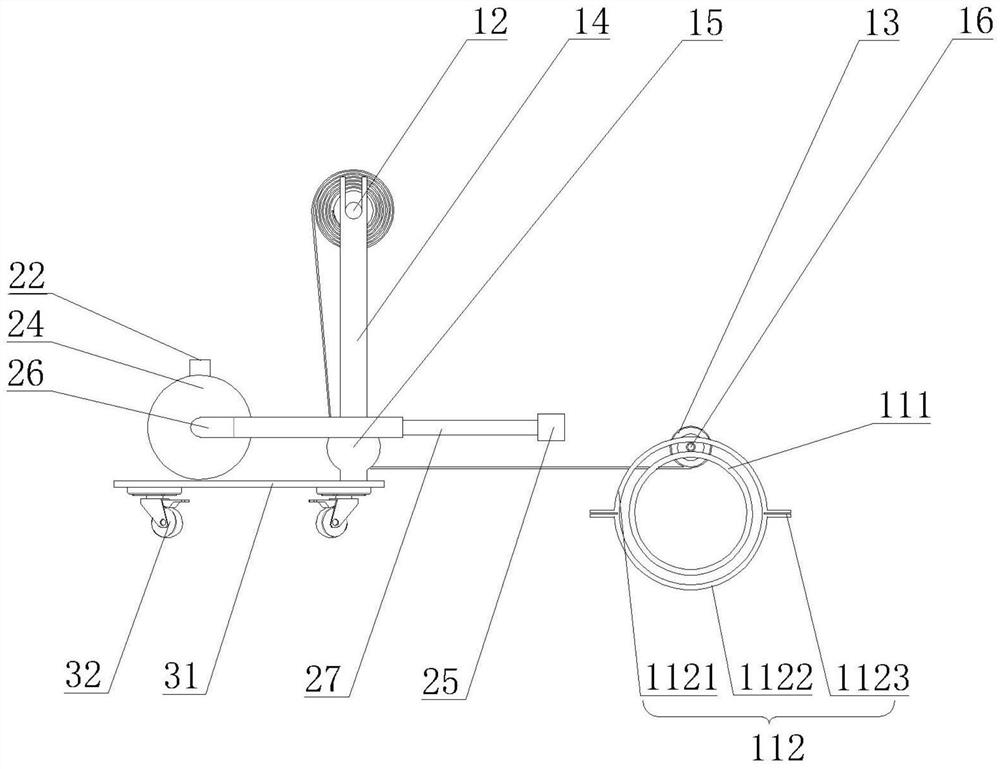

[0048] This embodiment provides a repair and maintenance device, such as figure 1 As shown, the repair and maintenance device includes a moving mechanism 3, the moving mechanism 3 includes a bearing plate 31 and a roller 32, the bearing plate 31 plays the role of integral support, the roller 32 is arranged at the bottom of the bearing plate 31, and the roller 32 is preferably locked. The universal wheel can freely change the rolling direction of the roller 32 along the horizontal direction, and can lock the current position. The rolling of the roller 32 can drive the bearing plate 31 to the destination, improving the adaptability to environmental changes in the repairing process.

[0049]During the maintenance process of pipelines by using the repairing and maintenance device, the buried pipelines are subject to environmental corrosion or collision, which may easily lead to damage and cracks in the pipeline itself. To this end, the repairing and maintenance device includes a ...

Embodiment 2

[0064] In this embodiment, on the basis of the first embodiment, the refinement of the carrying area of the mobile mechanism 3 is added.

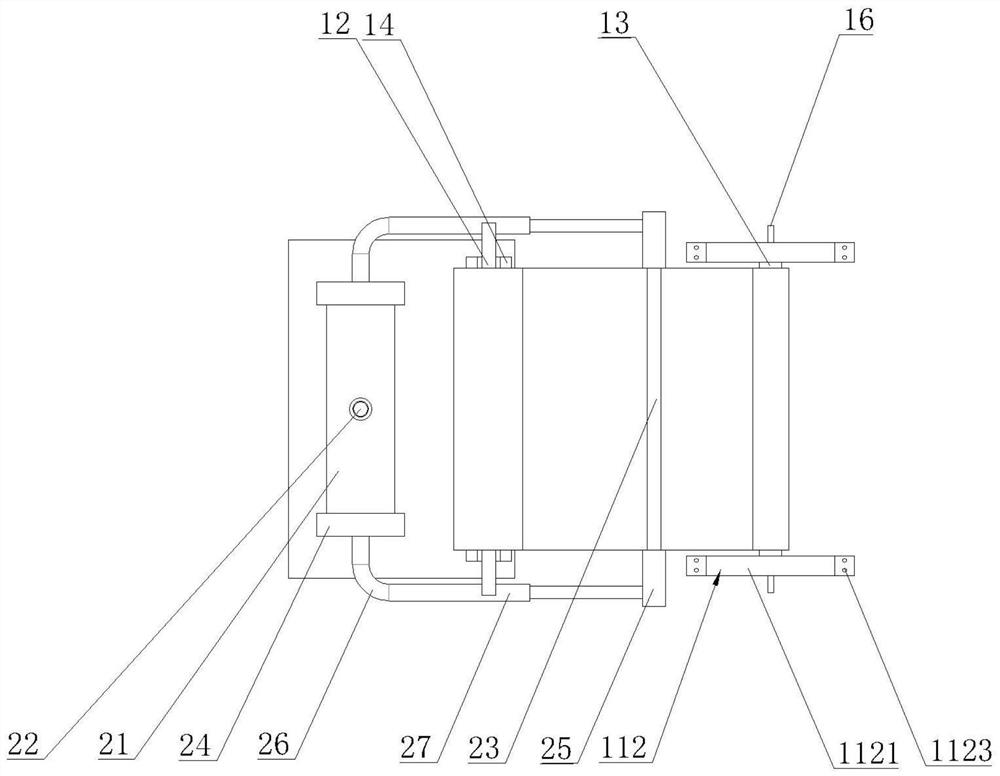

[0065] A repair and maintenance device provided in this embodiment also includes a spraying mechanism 2, such as Figure 5 As shown, the spraying mechanism 2 is arranged on the carrying plate 31 for spraying the antiseptic to the protective film, and the carrying plate 31 provides the necessary installation space for the spraying mechanism 2 . When it is necessary to spray preservatives on the protective film wrapped on the workpiece to be maintained, it is generally sprayed manually, resulting in uneven thickness and discontinuity of the sprayed layer. The requirements for the spraying technology of personnel are harsh, and the spraying time is relatively long, which affects maintenance efficiency.

[0066] In order to solve this problem, the spraying mechanism 2 includes a box body 21, a spray pipe 23 and a heating seat 24. The box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com