Workpiece online cleaning station of horizontal machining center flexible line

A machining center and flexible wire technology, applied in metal processing machinery parts, metal processing equipment, cleaning methods using liquids, etc., can solve the problems of inability to achieve unattended operation, low degree of automation, and difficult to clean the inner cavity of workpieces, etc. Achieve the effect of unattended operation, high degree of automation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

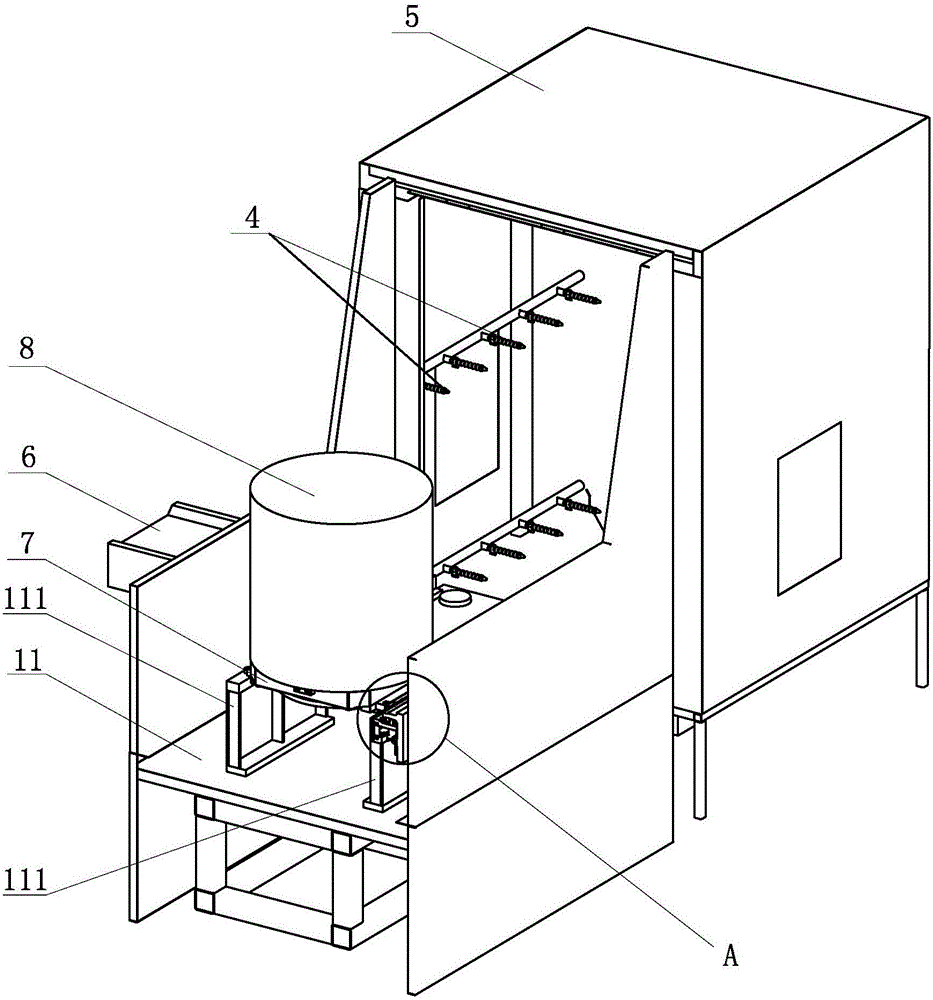

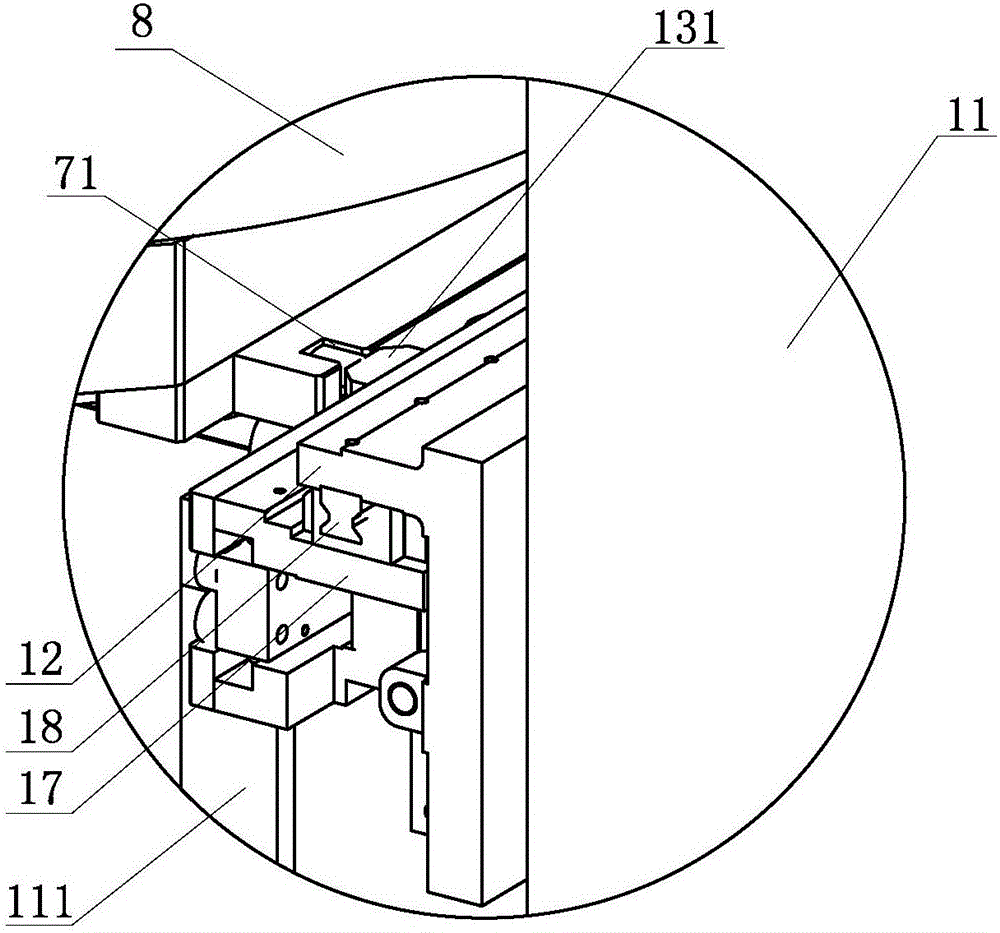

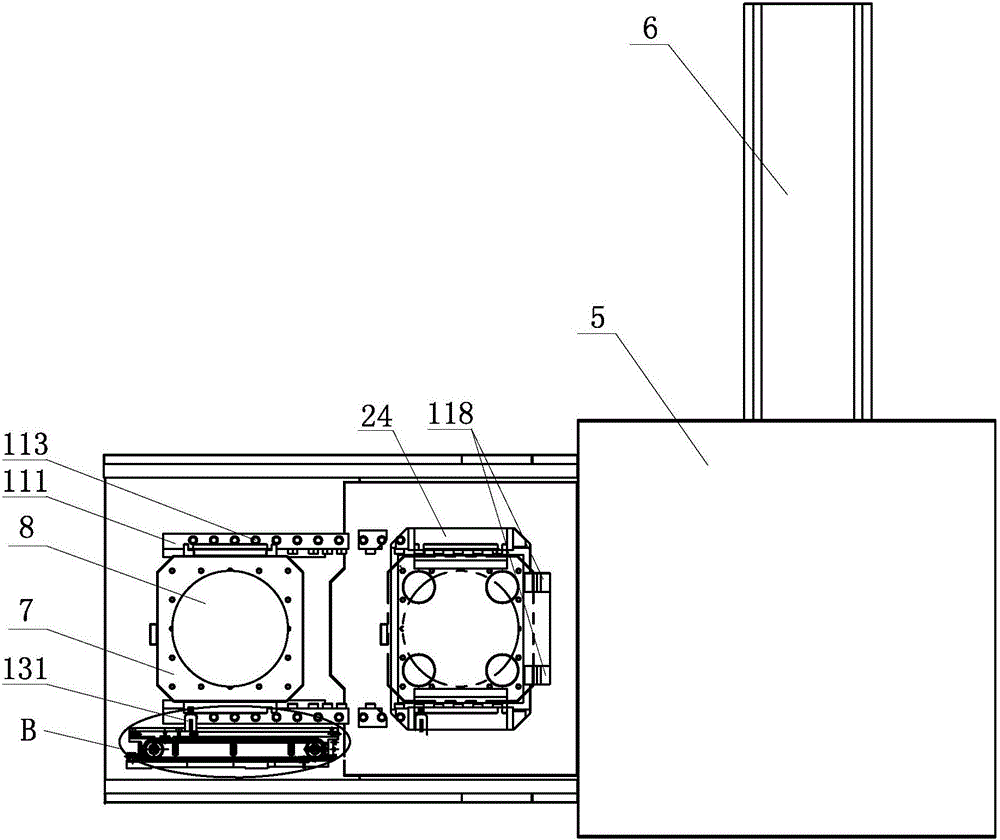

[0025]The workpiece online cleaning station of the flexible line of the horizontal machining center of Embodiment 1, as shown in the figure, includes a conveying device, a turning device, a rotating device, a spraying device and a chip removal device 6, and the conveying device includes a base 11 and a base mounted on the base 11. The sliding seat 12, the sliding body 13, the first driving mechanism and the chain transmission mechanism, the sliding seat 12 is slidably connected to the base 11, the output end of the first driving mechanism is connected to the sliding seat 12, and the sliding body 13 is slidably connected to the sliding seat 12, the chain transmission mechanism includes a chain 15 and two sprockets 16, the two sprockets 16 are installed on the slide 12 front and back, the chain 15 is wound on the two sprockets 16, and one end of the chain 15 is fixed on the base 11 , the other end of the chain 15 is fixed on the sliding body 13, the sliding body 13 is fixed with ...

Embodiment 2

[0028] The workpiece online cleaning station of the flexible line of the horizontal machining center of Embodiment 2, as shown in the figure, includes a conveying device, a turning device, a rotating device, a spraying device and a chip removal device 6, and the conveying device includes a base 11 and a base mounted on the base 11. The sliding seat 12, the sliding body 13, the first driving mechanism and the chain transmission mechanism, the sliding seat 12 is slidably connected to the base 11, the output end of the first driving mechanism is connected to the sliding seat 12, and the sliding body 13 is slidably connected to the sliding seat 12, the chain transmission mechanism includes a chain 15 and two sprockets 16, the two sprockets 16 are installed on the slide 12 front and back, the chain 15 is wound on the two sprockets 16, and one end of the chain 15 is fixed on the base 11 , the other end of the chain 15 is fixed on the sliding body 13, the sliding body 13 is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com