Beverage bottle/can automatic collecting and classifying robot

An automatic recycling and robotic technology, applied in the field of robotics, can solve the problems of difficult sorting and reprocessing, inconvenient for cleaning workers to collect for a long time, and poor awareness of garbage sorting, so as to achieve efficient recycling and sorting work, save labor, and increase the amount of storage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

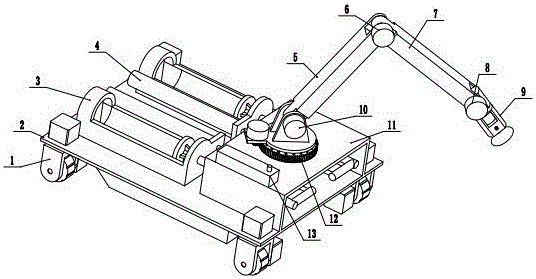

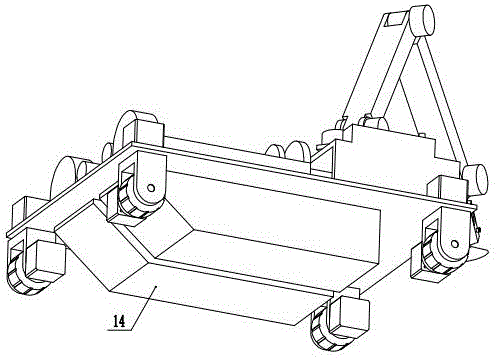

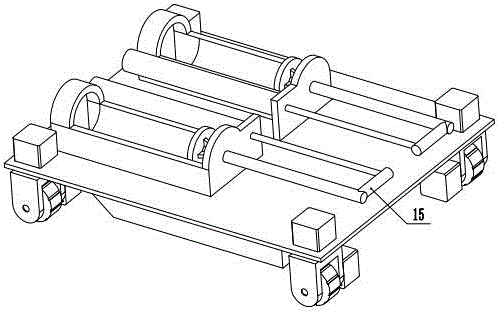

[0022] Such as Figure 1 to Figure 8 As shown, an automatic recycling and sorting robot for beverage bottles and cans, including four wheels 1, a chassis 2, two placement slots 3, two electric cylinders 4, a first connecting rod 5, an elbow motor 6, and a second connecting rod 7 , wrist motor 8, actuator 9, shoulder motor 10, mechanical arm mounting base 11, slewing bearing 12, vacuum pump 13, collection box 14, two ejector rods 15, rotating motor 16, gear 17, base 18, and It is characterized in that: the chassis 2 is a rectangular flat plate structure, and four circular through holes are opened at the four corners; the steering motors 101 of the four wheels 1 are respectively installed vertically at the four circular through holes at the four corners of the chassis 2 The two placement grooves 3 are in the shape of a dome and a square bottom, one end is processed with a boss with a circular through hole, and the bottom of the other end has a gap, and the gaps are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com